Processing apparatus

a processing apparatus and processing technology, applied in the field of processing apparatuses, can solve the problem that it is difficult to reduce the influence degree of particles on wafers sufficiently, and achieve the effect of preventing object pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

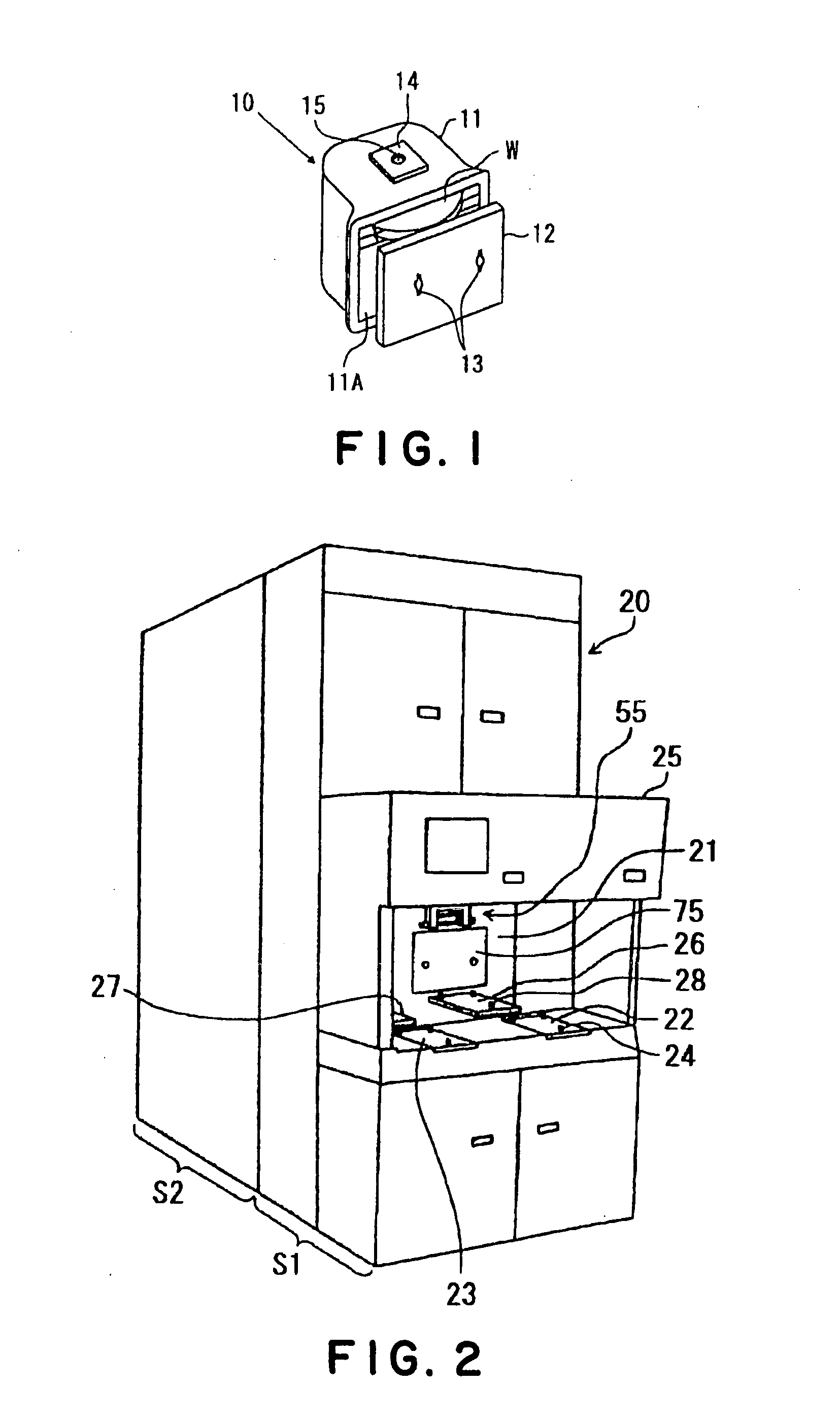

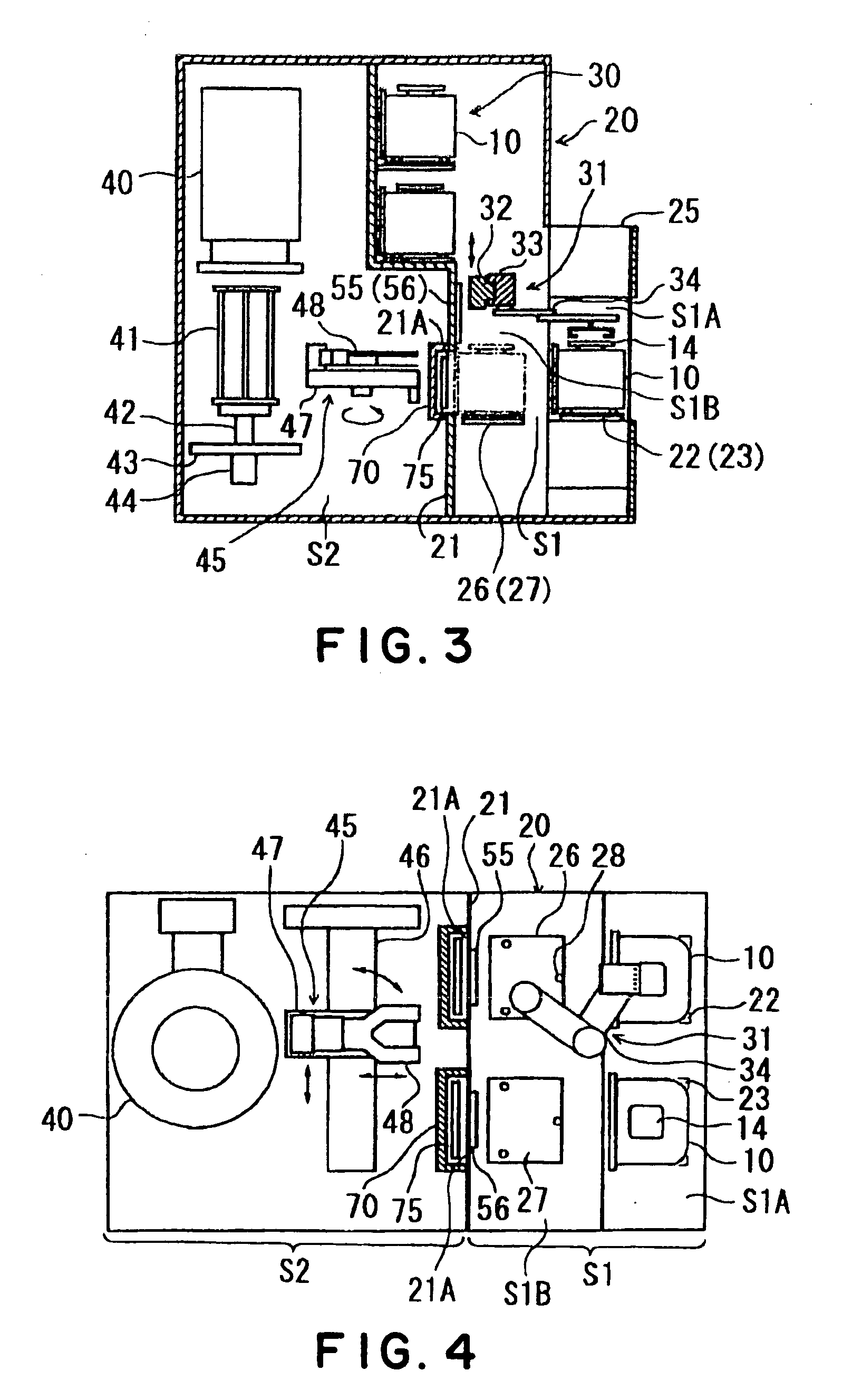

[0034] In a processing apparatus of the present invention, a hermetic container containing an object to be processed is placed at a predetermined position, and then the object to be processed is taken out from the container, and conveyed into an inside space area, which is maintained under a clean atmosphere, to be subjected to a predetermined process.

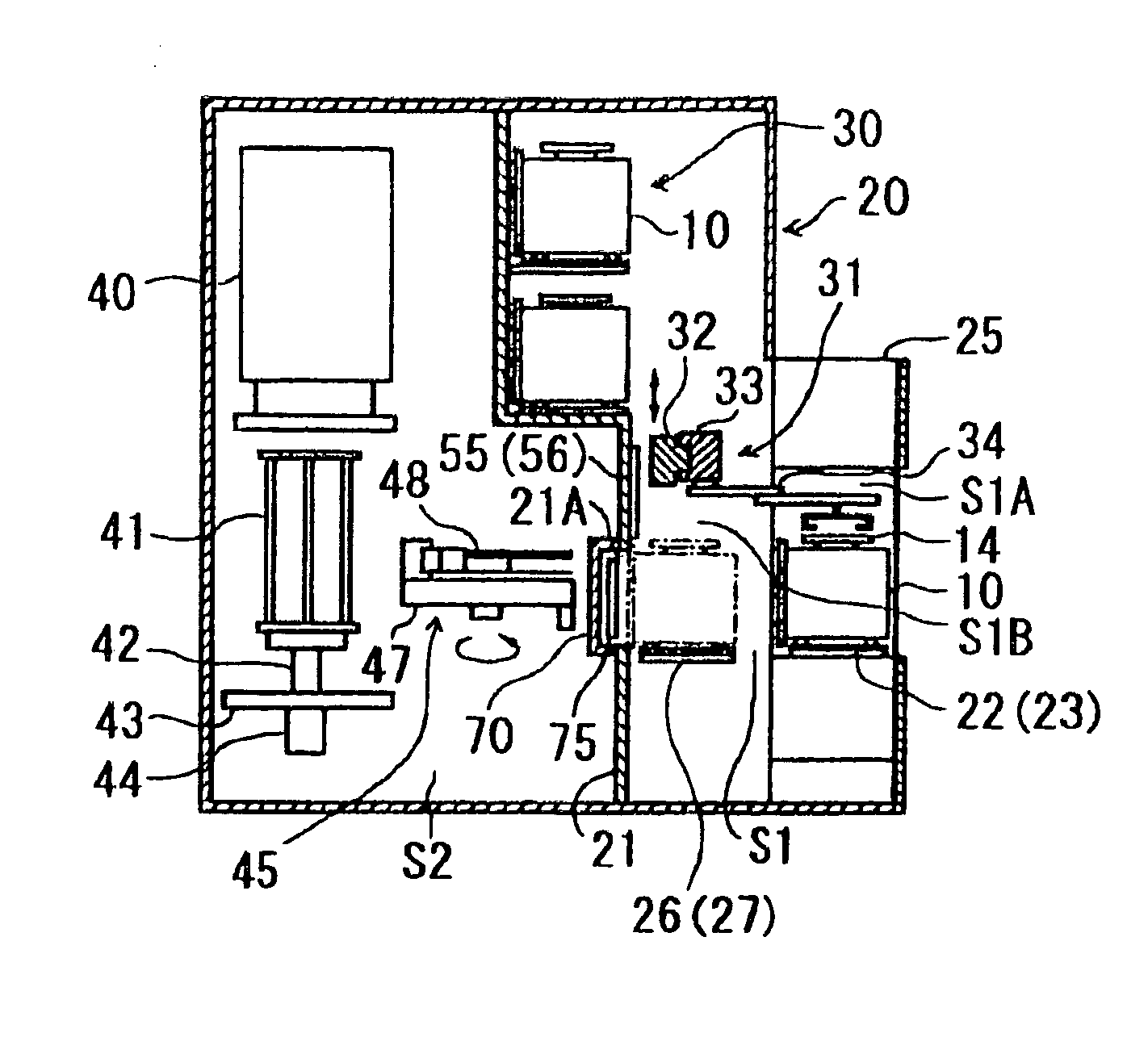

[0035] A carrier 10 including a main carrier body 11 is used, for example, as a container containing the object to be processed, as shown in FIG. 1. A taking-out port 11A is opened at one surface of the main carrier body 11. The taking-out port 11A is closed by a lid 12 that is provided to be removable. The carrier 10 is, for example, made of resin. The object to be processed is, for example, a wafer W whose diameter is 300 mm. The carrier 10 is composed so as to be capable of holding a plurality of, for example, 25 wafers W in a tier-like manner.

[0036] The lid 12 of the carrier 10 includes a not-shown latch mechanism (a lock mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com