Cartridge element for dust collector

a technology of cartridge elements and dust collectors, which is applied in the directions of transportation and packaging, separation processes, filtration separation, etc., can solve the problems of low space utilization rate of cartridge elements, affecting the fixing effect, and the method may not tightly seal the flang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

A. the Invention

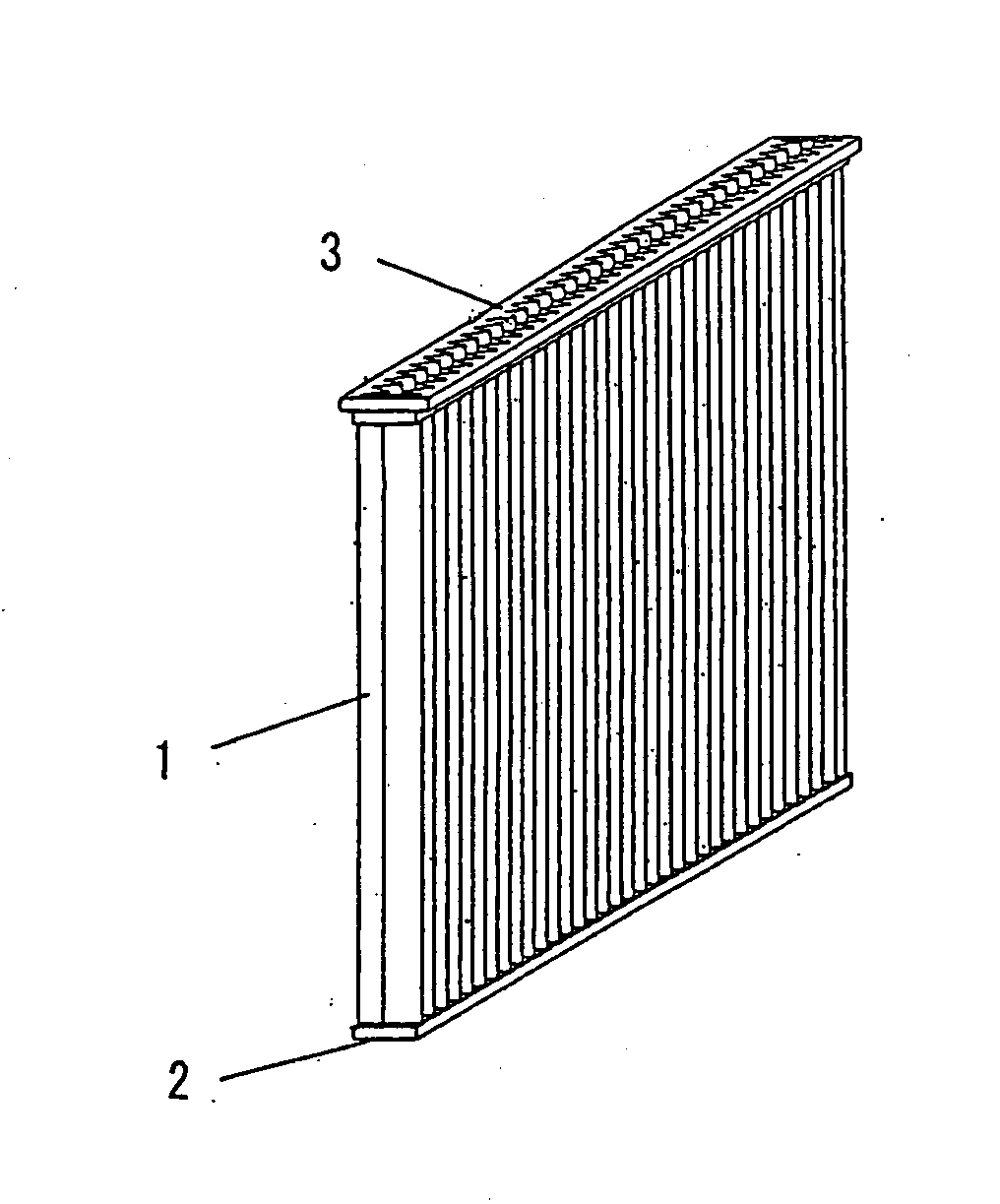

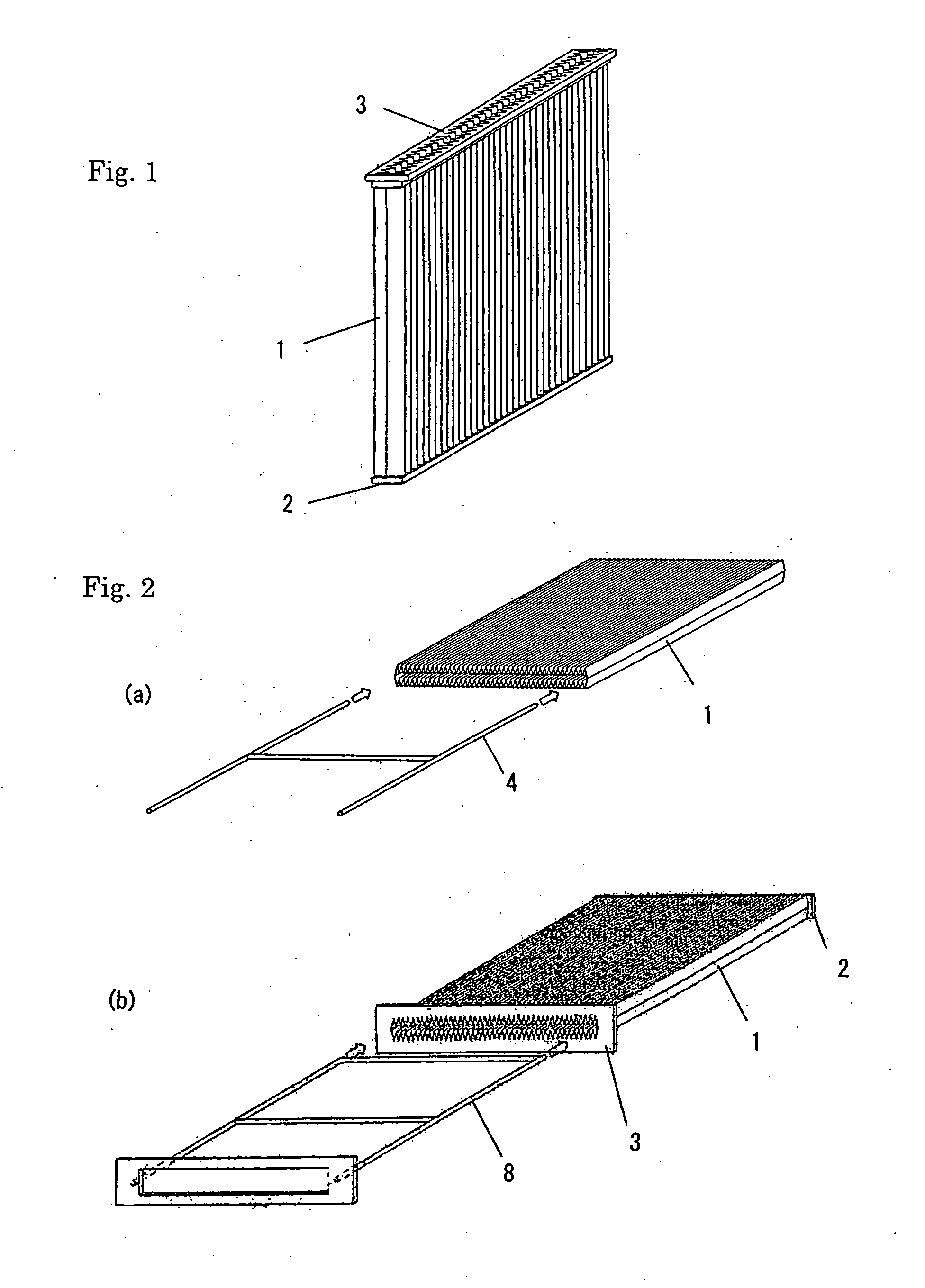

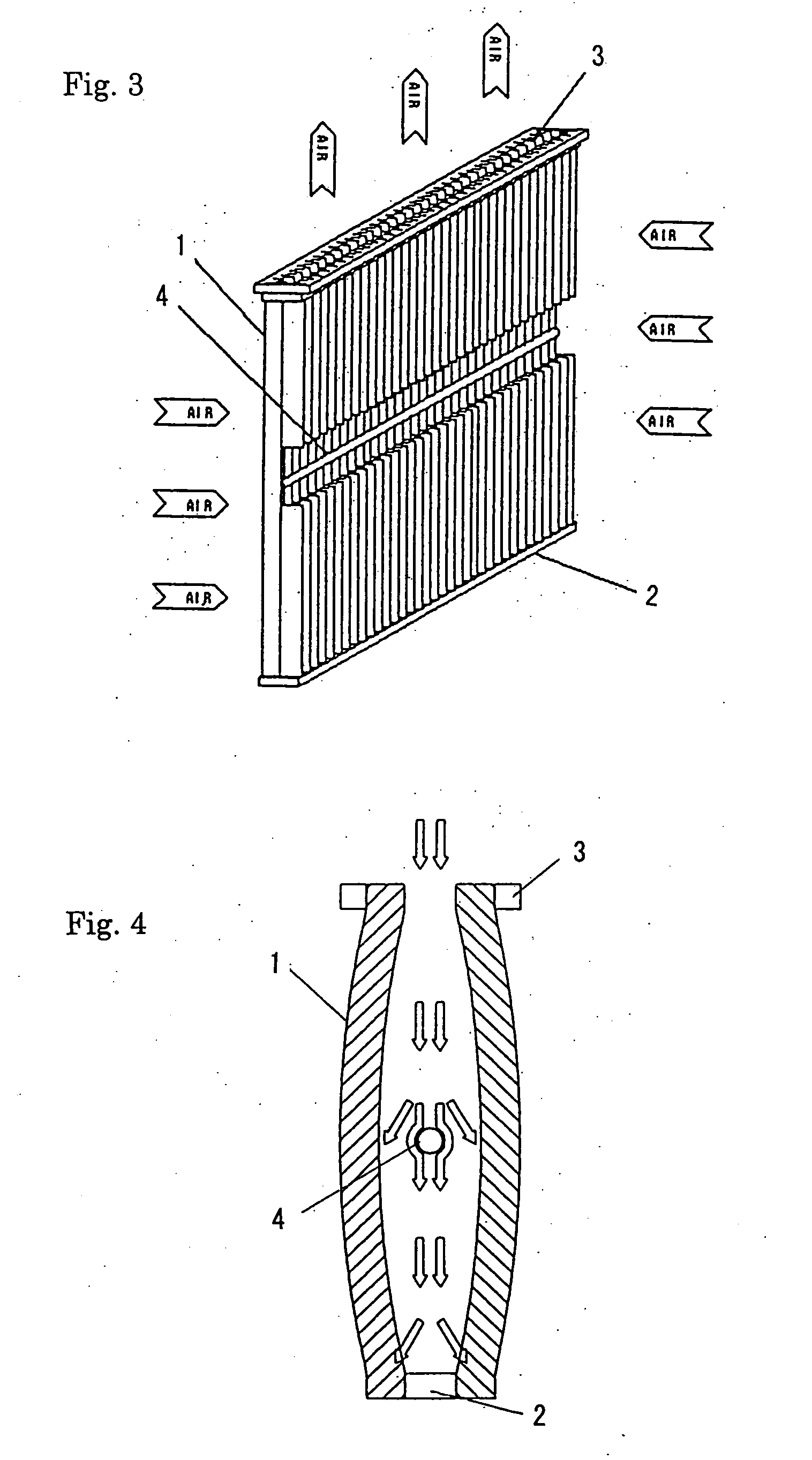

[0062] Now we discuss the embodiment of the plate-type cartridge element of the invention.

[0063] The first embodiment can achieve the function discussed above by making a cartridge element into a plate-type element, as follows.

[0064] First, the space for the elements in a dust collector can be utilized effectively and the rate of the use of the space by the element can be increased by making the cartridge element into a plate-type element.

[0065] The plate-type-cartridge element of this embodiment is one that substantially has the shape of a plane plate when it is installed in a dust collector. The sectional view of it is rectangular. The ratio of the long and short sides of the rectangle is 1:0.08-1:0.15.

[0066]“Pleated” of this embodiment denotes being made with a configuration that has cross section in the shape of successive Vs. Any angles of the gradients of the two sides of every V-shape are acceptable. Both of them may be at the same angle or one of them may...

second embodiment

B. the Invention

[0079] Now, we discuss the second embodiment of the invention in detail. The embodiment uses a plate-type cartridge element 15 as a cartridge element based on drawings. As shown in FIG. 7, at the bottom of a duct 11 that is installed in a predetermined position in a dust collector, guiding members 12 are fixed at intervals and have more than one inclined elliptic hole 12a. Inside each guiding member 12, a drilled rail 13 that has connecting holes 13a that correspond to the inclined elliptic holes 12a is attached (see FIG. 9).

[0080] The guiding members 12 and the rails 13 are coupled by the coupling devices 14 that are inserted through the inclined elliptic holes 12a and the connecting holes 13a. The rails 13 have a sliding member 16, which has more than one opening 16a to be inserted in the plate-type cartridge elements 15. More than one (in this embodiment, three) plate-type cartridge elements 15 are inserted in the openings that are made on the sliding member 16. ...

third embodiment

C. the Invention

[0095] Now, we discuss the third embodiment of the invention in detail based on the drawings. In reference to FIG. 12, on the upper part of each of the filtering chambers that are stacked and form a number of rows (three rows in this embodiment) and that communicate with each other, a number of ducts 32 are installed. They are spaced apart from each other (see FIG. 14). In each filtering chamber 31, the plate-type cartridge elements are installed and each of them is attached under the duct 32 and is detachable.

[0096] Now, we discuss the plate-type cartridge element 33. In this embodiment, “plate-type” means substantially having the shape of a plane plate as a whole, and a “plate-type cartridge element” means a plate-type filter unit that can be easily attached and detached. In reference to FIG. 15, we specifically discuss the plate-type cartridge element 33 of this embodiment as follows. A filter 33b, which is composed of two sheets of pleated filter medium 33a and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com