Encapsulated flexible polyurethane foam and method for making polyol to form foam

a flexible polyurethane foam and polyurethane technology, applied in the field of encapsulated flexible polyurethane foam and method for making polyol to form foam, can solve the problems of inconvenient use of petrochemical polyols, inability to meet the needs of industrial production,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

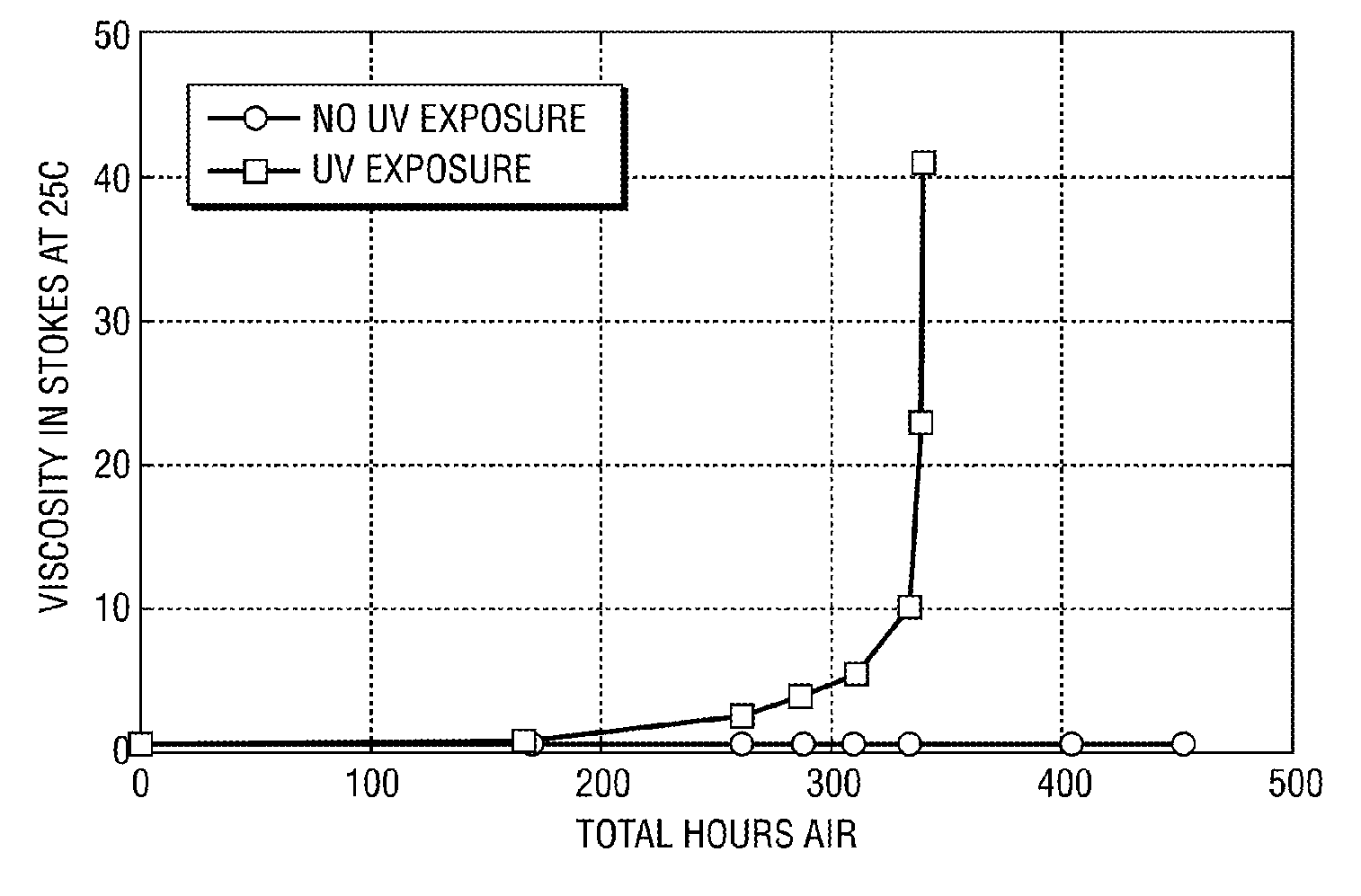

[0046] In one experiment, one (1) liter of cold pressed degummed soy oil, available from the Thumb Oilseed Producers' Cooperative of Ubly, Mich., was placed in a custom blown glass column. This experiment was conducted at room temperature, about 72 F. The quartz column allowed the degummed soy oil to be exposed to all of the UV light. In a first trial, an external UV lamp, available from Philips Electronics North America of New York City, N.Y., generated UV light at a wavelength of 315 nm, which was directed at the glass column. During the UV exposure, air was blown through the degummed soy oil. The results of this trial are found in Table 1 below. A Gardner bubble viscometer was utilized to measure the viscosity in stokes at 25 C. The percent volatiles produced was measured following the Ca2c-25 test method from the American Oil Chemists Society for testing volatiles.

TABLE 1Viscosity in stokesPercent volatilesTotal hours airTotal hours UVat 25 C.produced000.501661660.8502611702.5...

example 2

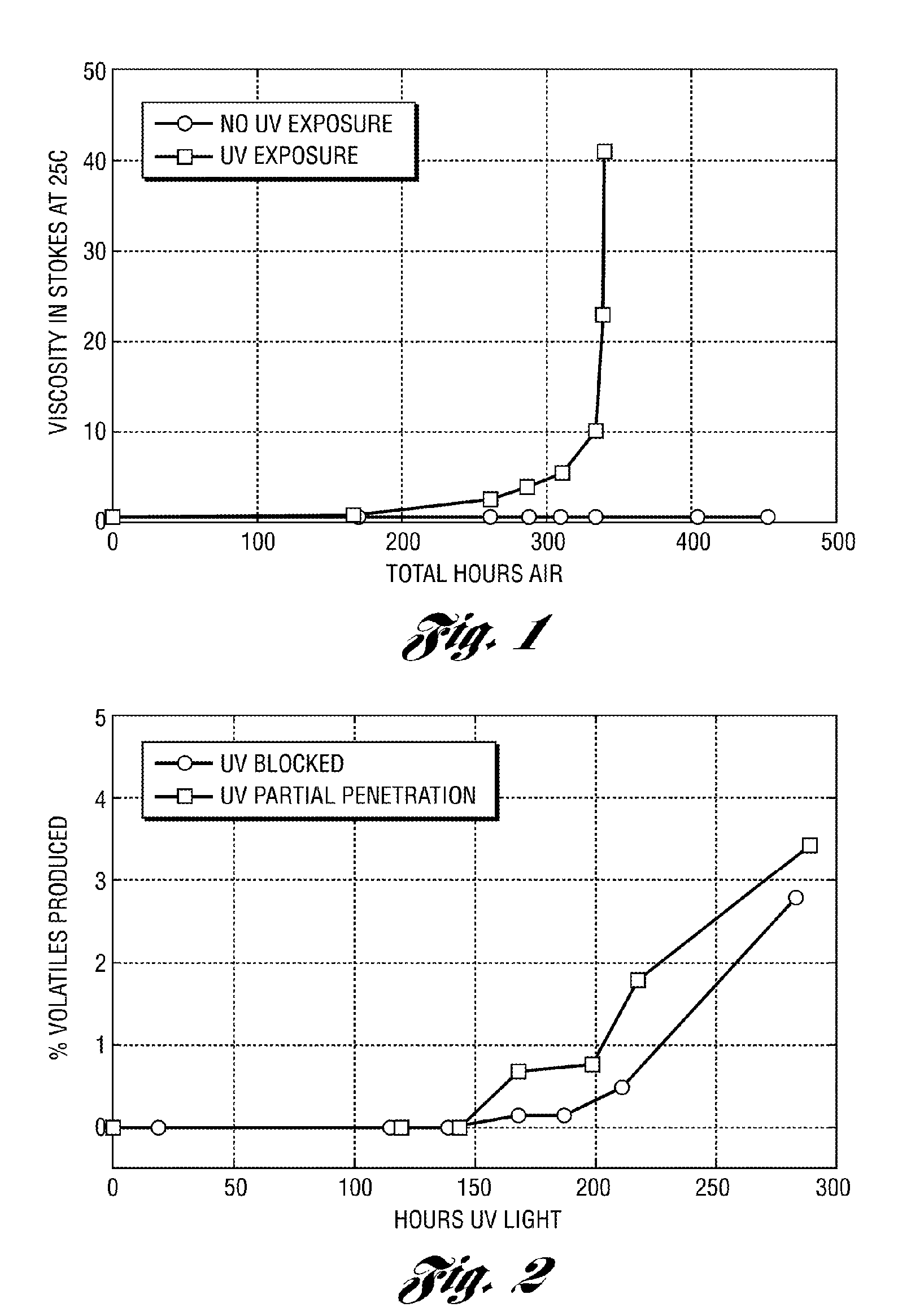

[0049] In another series of experiments, one (1) liter of cold pressed degummed soy oil, available from the Thumb Oilseed Producers' Cooperative of Ubly, Mich., was placed in a PYREX column that allowed some UV light to penetrate. UV light from an external UV lamp was directed at the PYREX column. The results of these experiments are found in Tables 3-6 below.

TABLE 3PercentageUVVis. in stokesVolatiles(nm)T (F.)Hrs airHrs UVat 25 C.Produced350 nm721201201.41.54

[0050]

TABLE 4PercentageUVVis. in stokesVolatiles(nm)T (F.)Hrs airHrs UVat 25 C.Produced315 nm7228628612.14.23315 nm72309309164.88

[0051]

TABLE 5PercentageUVVis. in stokesVolatiles(nm)T (F.)Hrs airHrs UVat 25 C.Produced315 nm22220202.25—315 nm22225252.65—315 nm22243434.850.478

[0052]

TABLE 6PercentageUVVis. in stokesVolatiles(nm)T (F.)Hrs airHrs UVat 25 C.Produced315 nm17525251.25—315 nm17525 @25 @5.5—and 72175 F.175 F.and 72and 72@ 72@ 72

example 3

[0053] In yet another experiment, degummed soy oil was placed in a PYREX column that allowed the passage of some UV light. UV light at 315 nanometers from a UV lamp was directed at the PYREX column. The experiment was conducted at a temperature of about 100 F. The results of this experiment are found in Table 7 below.

TABLE 7TotalViscosity in stokesPercentageTotal hours airhours UVat 25 C.Volatiles Produced000.501201200.501441440.6501681680.850.6819819810.7522172172.51.7782892896.153.426

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com