Internal turbine-like toroidal combustion engine

a combustion engine and turbine-like technology, applied in the direction of machines/engines, efficient propulsion technologies, mechanical apparatuses, etc., can solve the problems of engine evolution, engine but were dangerous and inefficient, and added to the complexity of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

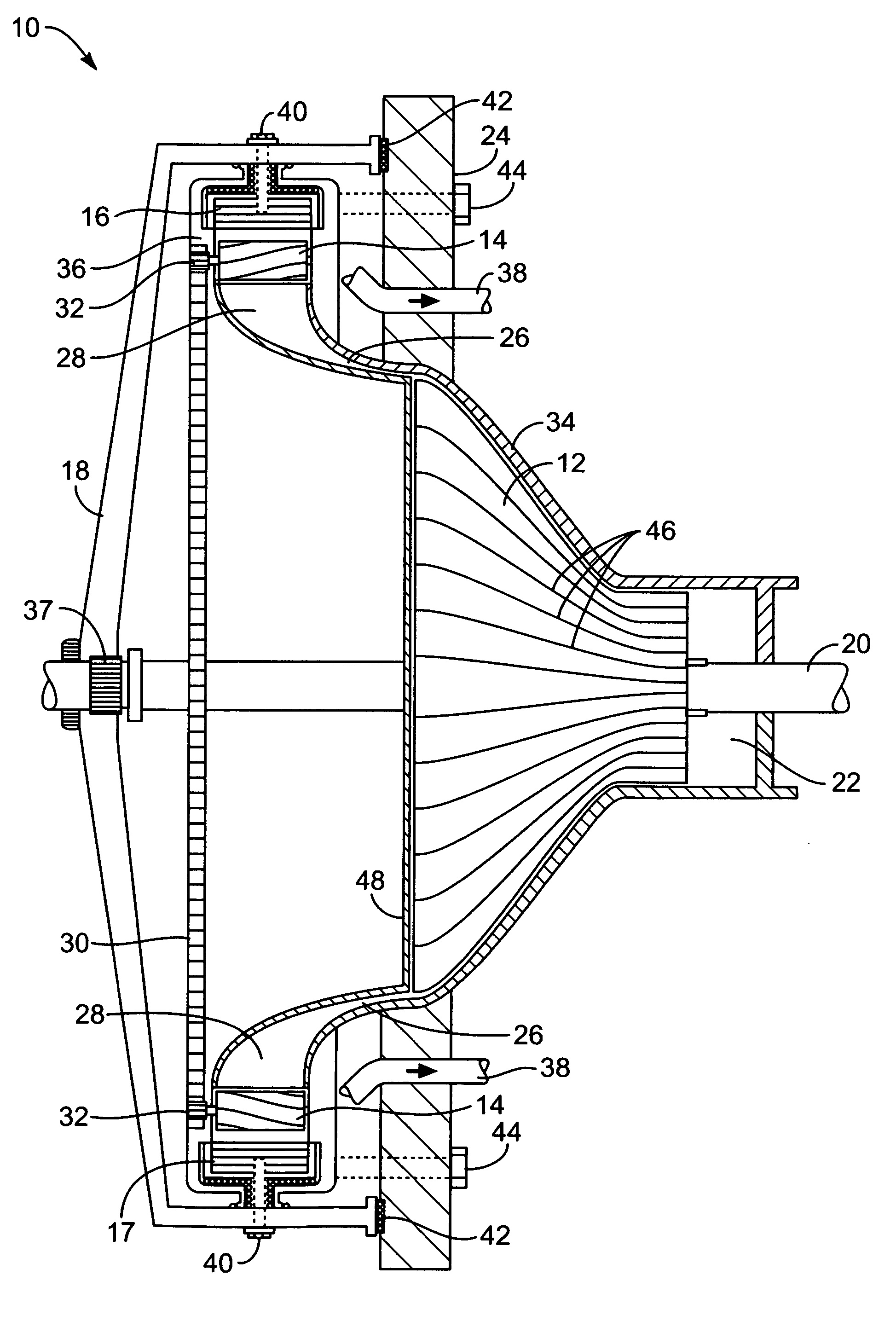

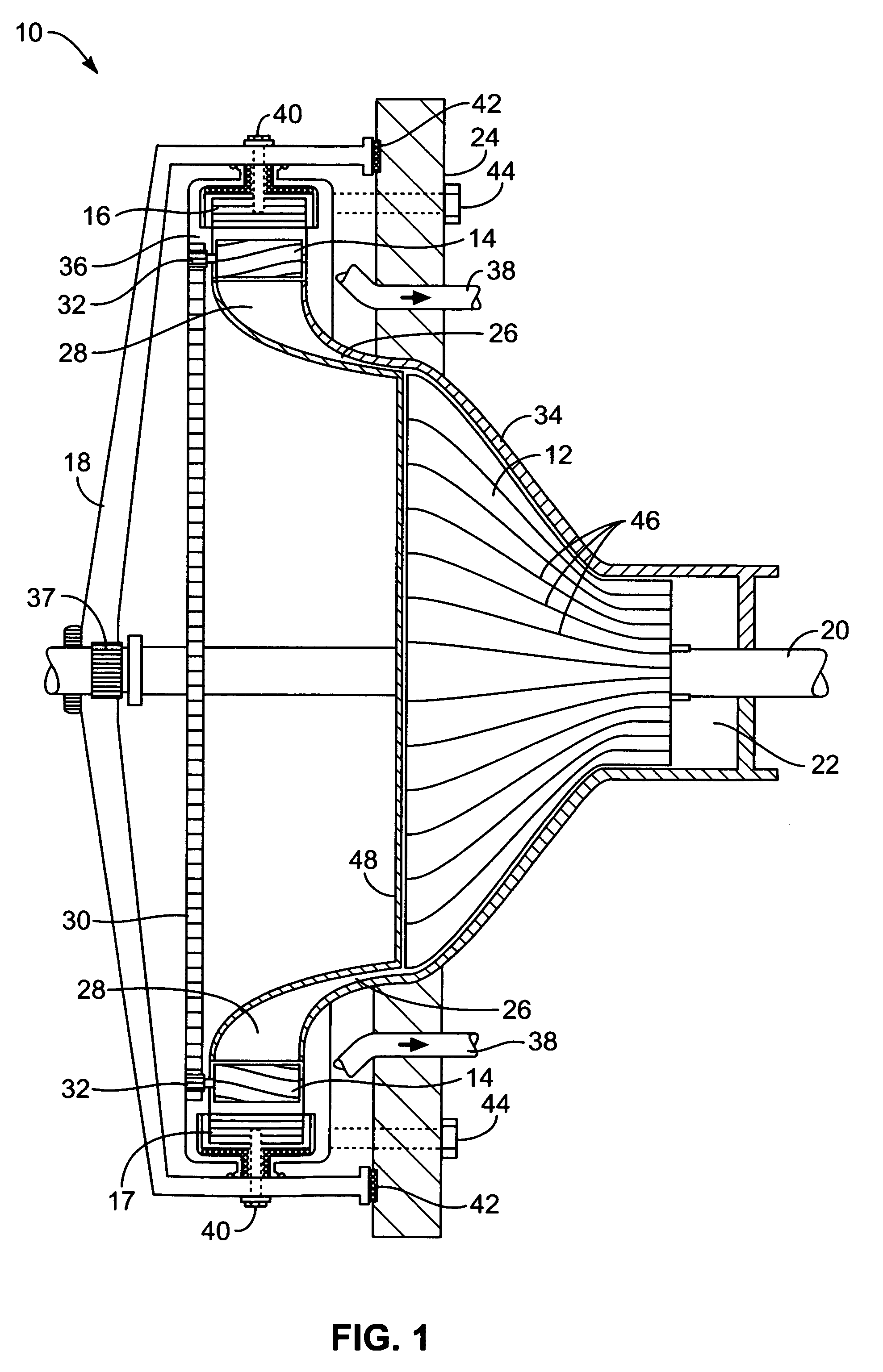

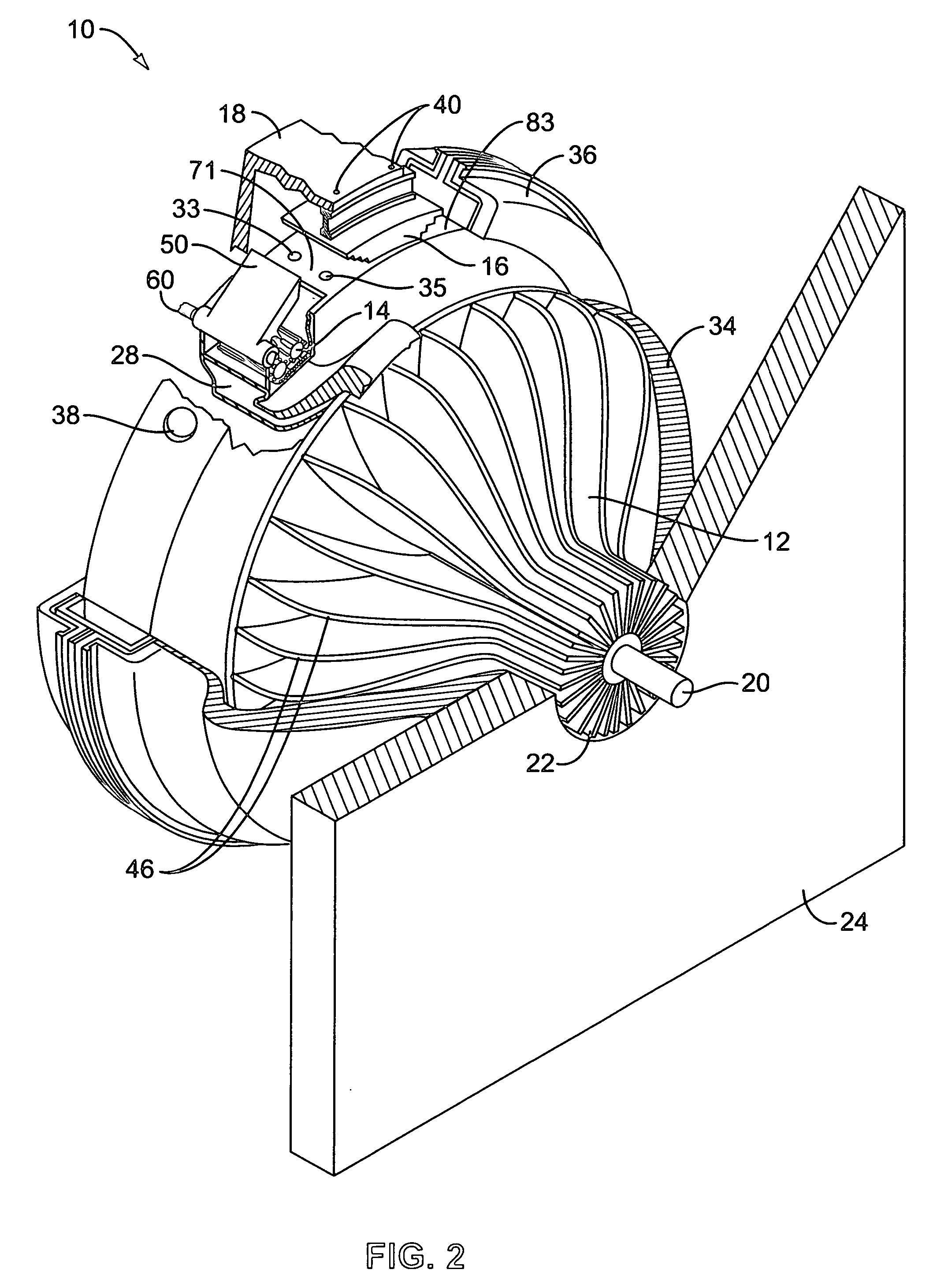

[0031] A novel engine is disclosed that is an improvement over the prior art. Engine 10 is illustrated in FIGS. 1 and 2 and is a multistage compression, air chamber trap engine with turbine like features that eschews reciprocating pistons found in conventional reciprocating piston combustion engines. Engine 10 includes a first compressor stage or compressor 12, which rotates within a compressor housing or shell 34, that is further coupled to two second compressor stages or compressors 14 via compressed air path 22. Compressor shell 34 connects to an engine frame 24, which provides support and rigidity for engine 10. Compressed air from path 26 feeds to an air feed 28 that is coupled to both second compressors 14. Each compressor 14 provides a second compression action on the compressed air and mixes fuel with it just prior to combustion, which is used to extract energy and convert the force into useable work.

[0032] Engine 10 further includes an active or first race piston 16 that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com