Heat exchanger and method of manufacturing outside plate used for header tanks of heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will next be described in detail with reference to the drawings. These embodiments are implemented by applying a heat exchanger according to the present invention to a gas cooler of a supercritical refrigeration cycle.

[0054] In the following description, the upper, lower, left-hand, and right-hand sides of FIGS. 1 and 2 will be referred to as “upper,”“lower,”“left,” and “right,” respectively. Further, in the following description, the term “aluminum” encompasses aluminum alloys in addition to pure aluminum.

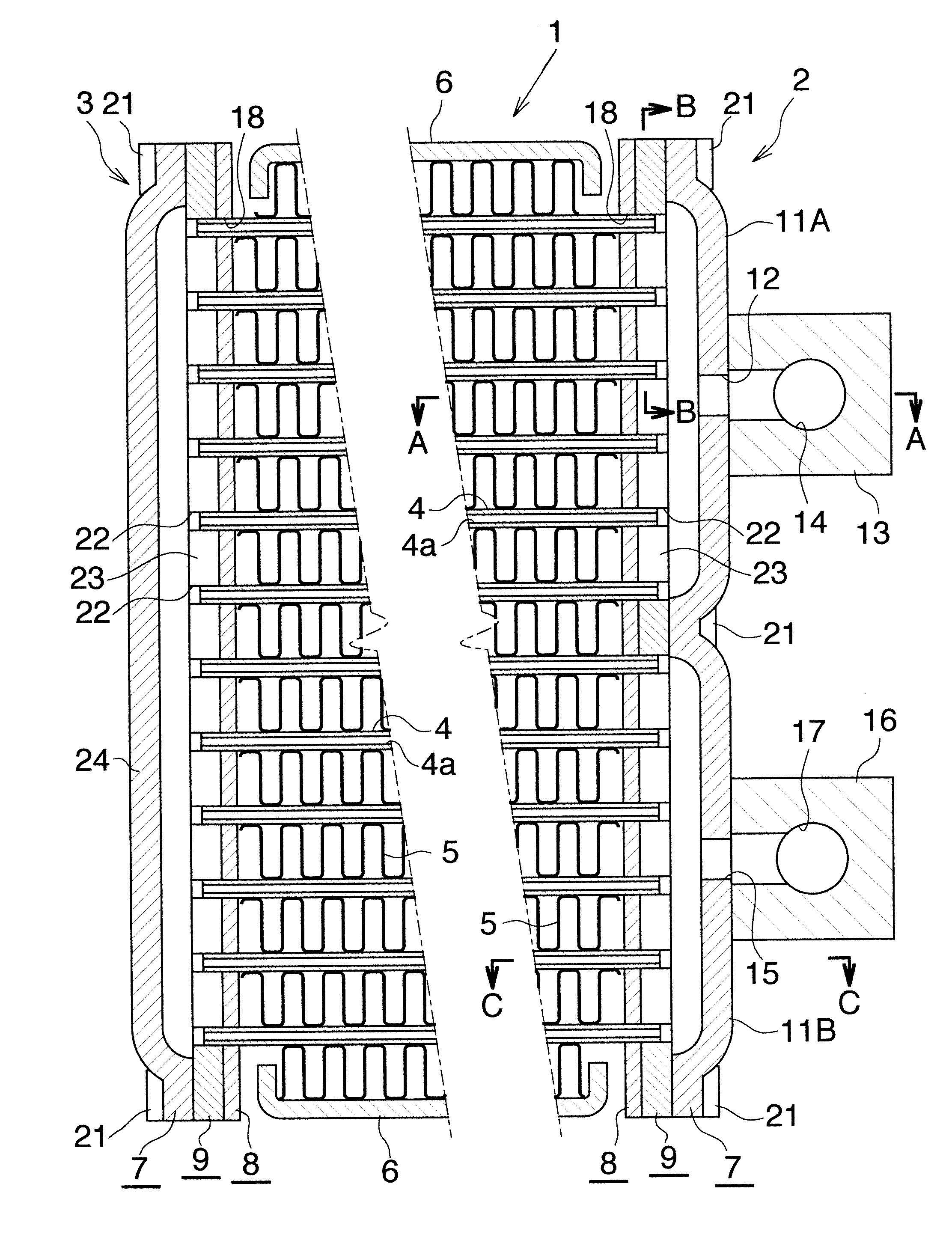

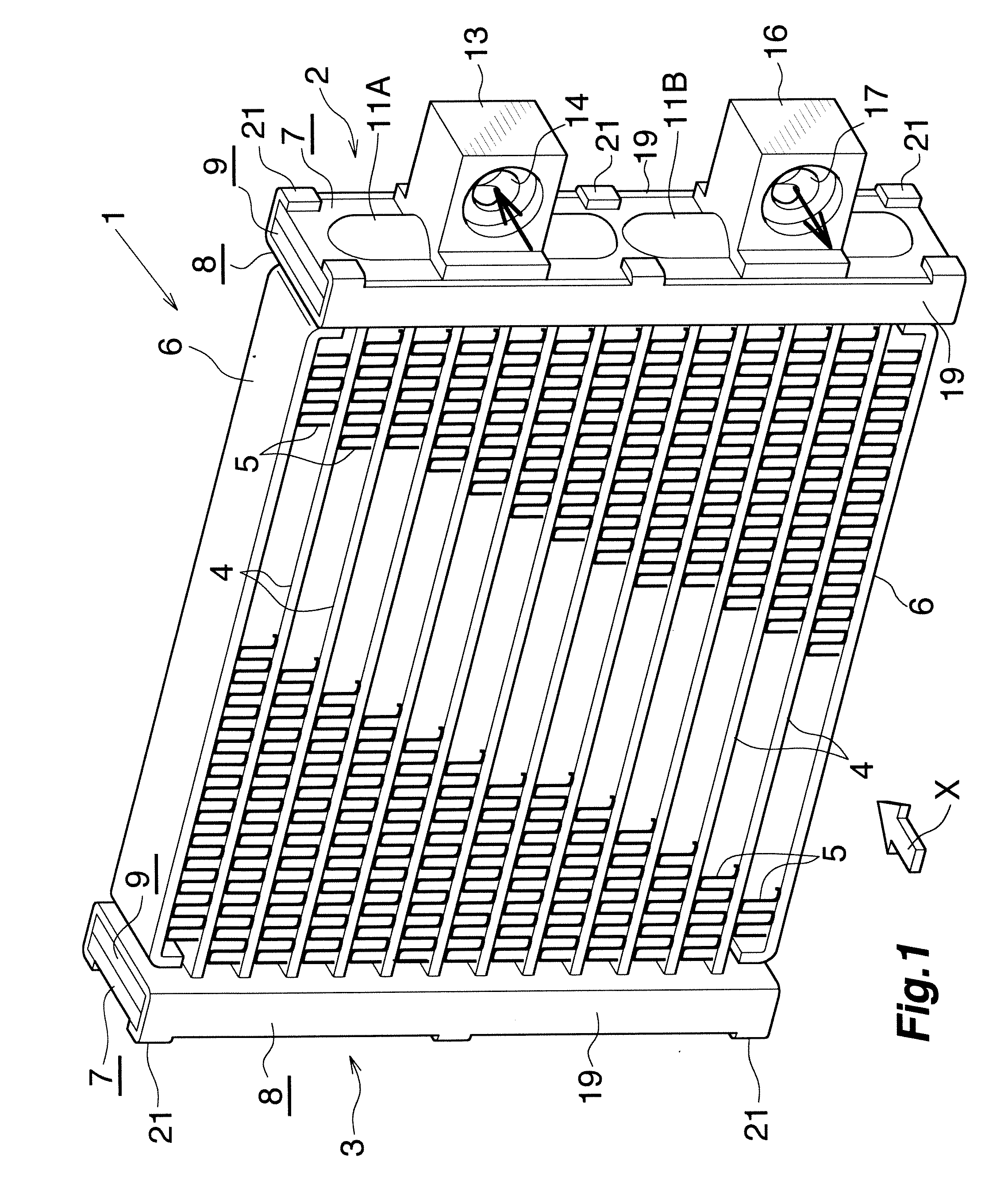

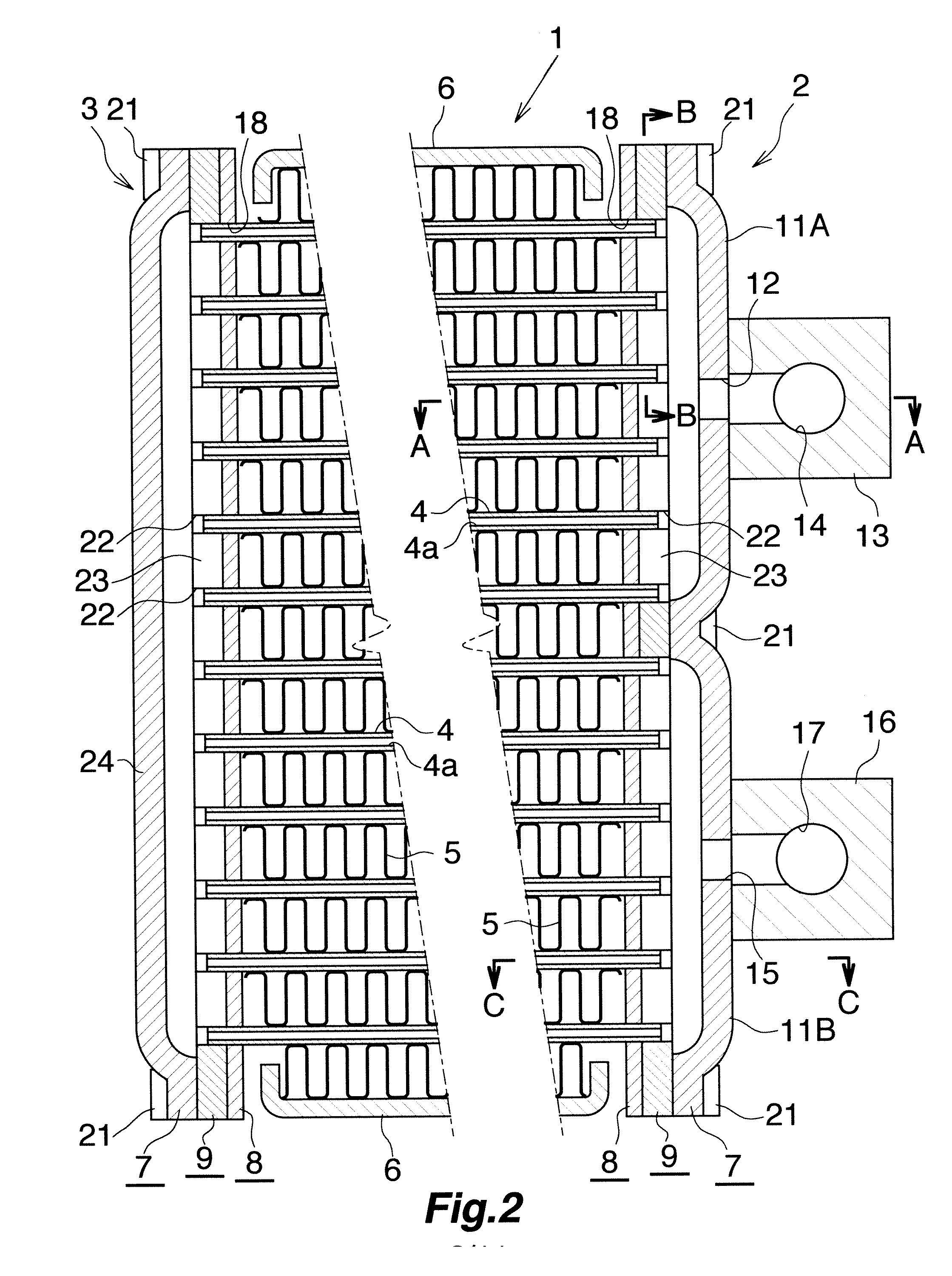

[0055]FIGS. 1 and 2 show the overall construction of a gas cooler to which the heat exchanger according to the present invention is applied. FIGS. 3 to 6 show the configuration of essential portions of the gas cooler of FIG. 1. FIGS. 7 to 9 show a method of manufacturing header tanks. FIGS. 10 and 11 show a heat exchange tube. FIG. 12 shows a method of manufacturing the heat exchange tube.

[0056] With reference to FIG. 1, a gas cooler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com