Optical system and optical apparatus including optical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

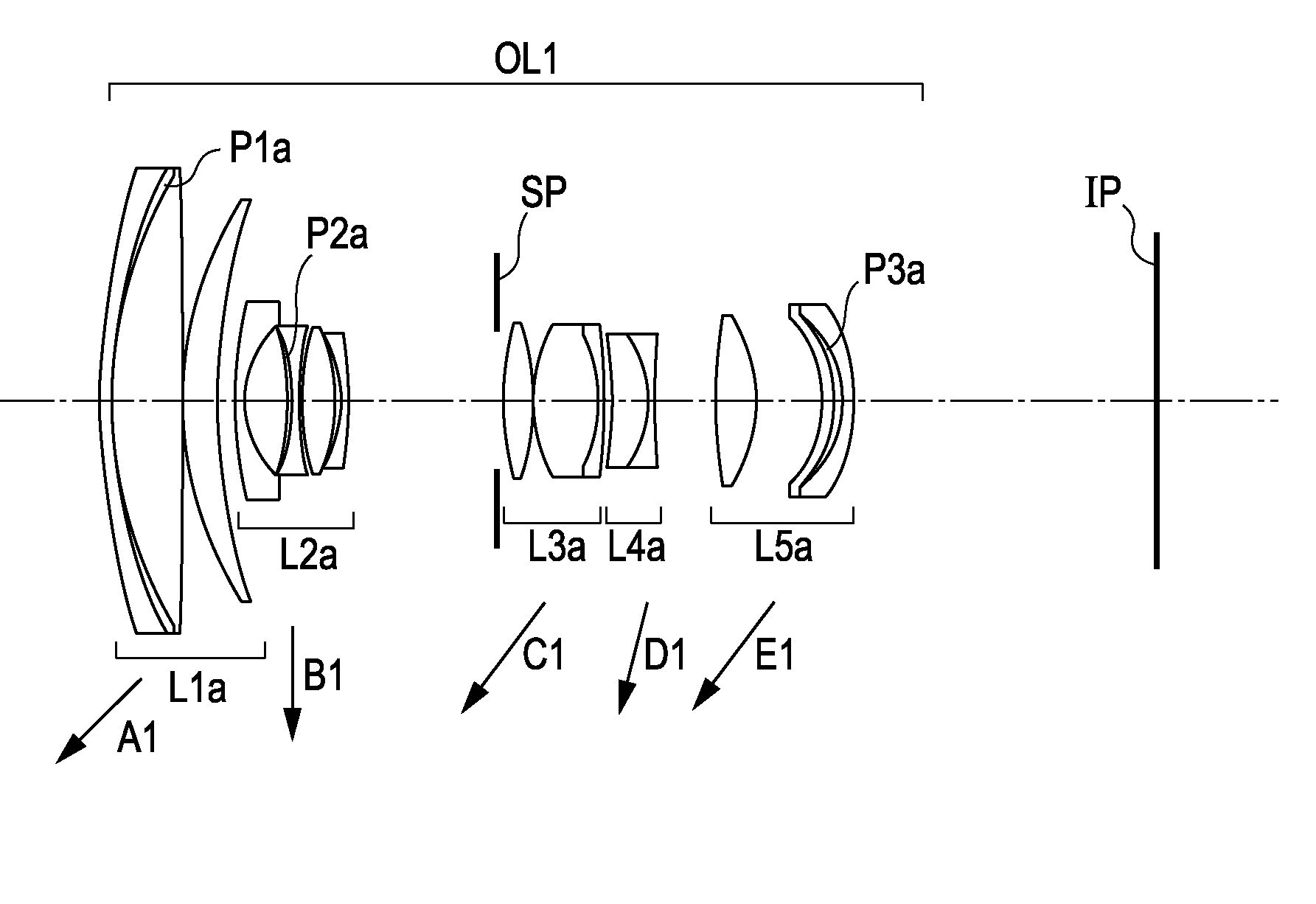

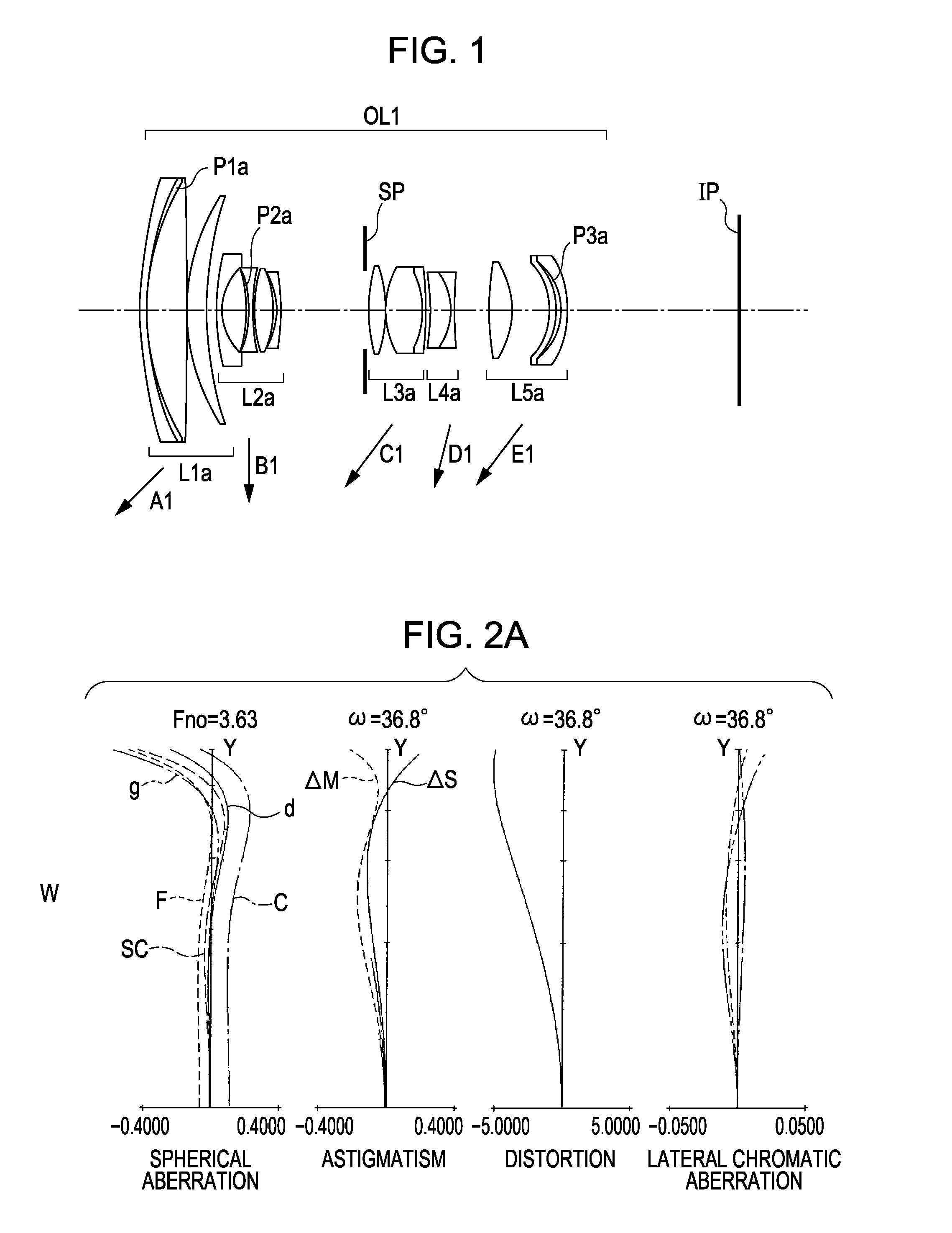

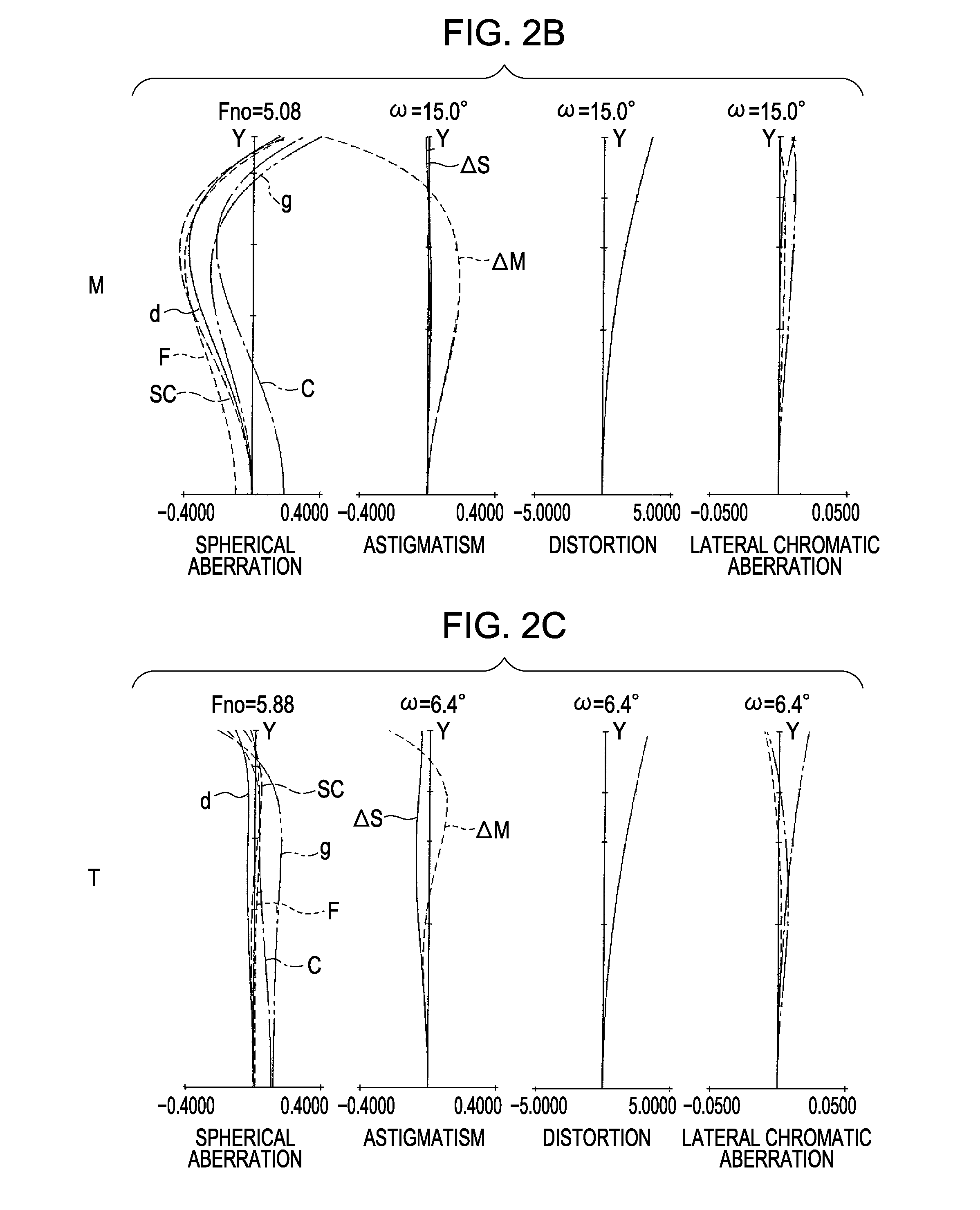

[0042]FIGS. 1, 3, 5, and 7 are cross-sectional views of lenses at a wide-angle end. FIGS. 2A to 2C, 4A to 4C, 6A to 6C, and 8A to 8C illustrate aberration at the wide-angle end (A), at an intermediate position of a zoom range (B), and at a telephoto end (C). FIGS. 10 and 12 illustrate aberration when a focus of an optical system is adjusted to an object at infinity.

[0043]Optical systems (e.g., OL1-OL6) according to exemplary embodiments of the present invention can be used for imaging and / or optical apparatus (e.g., silver-salt film cameras, digital still cameras, video cameras, telescopes, binoculars, projectors, copying machines, and other optical apparatus as known by one of ordinary skill in the relevant arts). In the cross-sectional views of the lenses, the left side is adjacent to an object (the anterior position), and the right side is adjacent to an image-taking side (the posterior position).

[0044]When the optical systems according to the exemplary embodiments of the present...

numerical example 1

[0099]

f=28.90˜193.15Fno=3.63˜5.88 2ω=73.6˜12.8

R1=102.694D1=1.50N1=1.846660ν1=23.9

R2=67.525D2=0.05N2=1.578566ν2=16.5

R3=57.448D3=9.29N3=1.603112ν3=60.6

R4=−938.598D4=0.12

R5=48.476D5=4.44N4=1.622992ν4=58.2

R6=82.382D6=variable

*R7=73.541D7=1.20N5=1.834807ν5=42.7

R8=13.885D8=5.65

R9=−33.988D9=0.60N6=1.578566ν6=16.5

R10=−24.239D10=1.00N7=1.834807ν7=42.7

R11=52.693D11=0.12

R12=30.334D12=4.52N8=1.755199ν8=27.5

R13=−21.950D13=0.60

R14=−17.654D14=0.90N9=1.772499ν9=49.6

R15=−69.021D15=variable

R16=SP D16=0.94

R17=43.224D17=4.08N10=1.487490ν10=70.2

R18=−30.236D18=0.15

R19=26.744D19=8.13N11=1.487490ν11=70.2

R20=−21.083D20=0.90N12=1.805181ν12=25.4

R21=−63.759D21=variable

R22=−51.876D22=4.69N13=1.740769ν13=27.8

R23=−14.998D23=0.90N14=1.882997ν14=40.8

R24=123.097D24=variable

R25=85.239D25=5.21N15=1.583126ν15=59.4

*R26=−20.371D26=8.80

R27=−15.933D27=1.50N16=1.698947ν16=30.1

R28=−16.645D28=1.01N17=1.635550ν17=22.7

R29=−14.231D29=1.50N18=1.805181ν18=25.4

R30=−24.910[0100]\Focal length 28.90 80.81 193.15[0101]Variable gap\[010...

numerical example 2

[0109]

f=28.90˜193.17Fno=3.63˜5.88 2ω=73.6˜12.8

R1=132.527D1=1.50N1=1.846660ν1=23.9

R2=49.733D2=2.52N2=1.635550ν2=22.7

R3=67.379D3=7.08N3=1.622992ν3=58.2

R4=984.359D4=0.12

R5=51.358D5=7.04N4=1.622992ν4=58.2

R6=234.151D6=variable

*R7=73.837D7=1.20N5=1.834807ν5=42.7

R8=14.793D8=5.59

R9=−44.796D9=0.21N6=1.578566ν6=16.5

R10=−37.512D10=1.00N7=1.834807ν7=42.7

R11=45.257D11=0.12

R12=27.772D12=4.32N8=1.755199ν8=27.5

R13=−30.460D13=1.02

R14=−19.218D14=0.90N9=1.772499ν9=49.6

R15=101.774D15=2.03N10=1.784723ν10=25.7

R16=−93.904D16=variable

R17=SP D17=0.70

R18=34.666D18=4.41N11=1.518229ν11=58.9

R19=−28.082D19=0.15

R20=37.367D20=4.95N12=1.517417ν12=52.4

R21=−20.919D21=0.30N13=1.635550ν13=22.7

R22=−18.412D22=0.90N14=1.846660ν14=23.9

R23=−118.206D23=variable

R24=−39.813D24=2.43N15=1.728250ν15=28.5

R25=−18.948D25=0.90N16=1.882997ν16=40.8

R26=−97.865D26=variable

R27=52.675D27=6.09N17=1.583126ν17=59.4

*R28=−20.674D28=1.27

R29=315.706D29=2.16N18=1.487490ν18=70.2

R30=−126.226D30=3.07

R31=−21.208D31=1.00N19=1.834000ν19=37.2

R32=284.744D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com