Liquid slag quick quenching apparatus and method

a liquid slag and quick technology, applied in heat treatment apparatus, furnace types, furnaces, etc., can solve the problems of generating an appreciable amount of dust, difficult handling and transportation of cooled slag in its powder form, and so as to reduce the amount of dust. , the effect of reducing the operating hours of front-end loaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

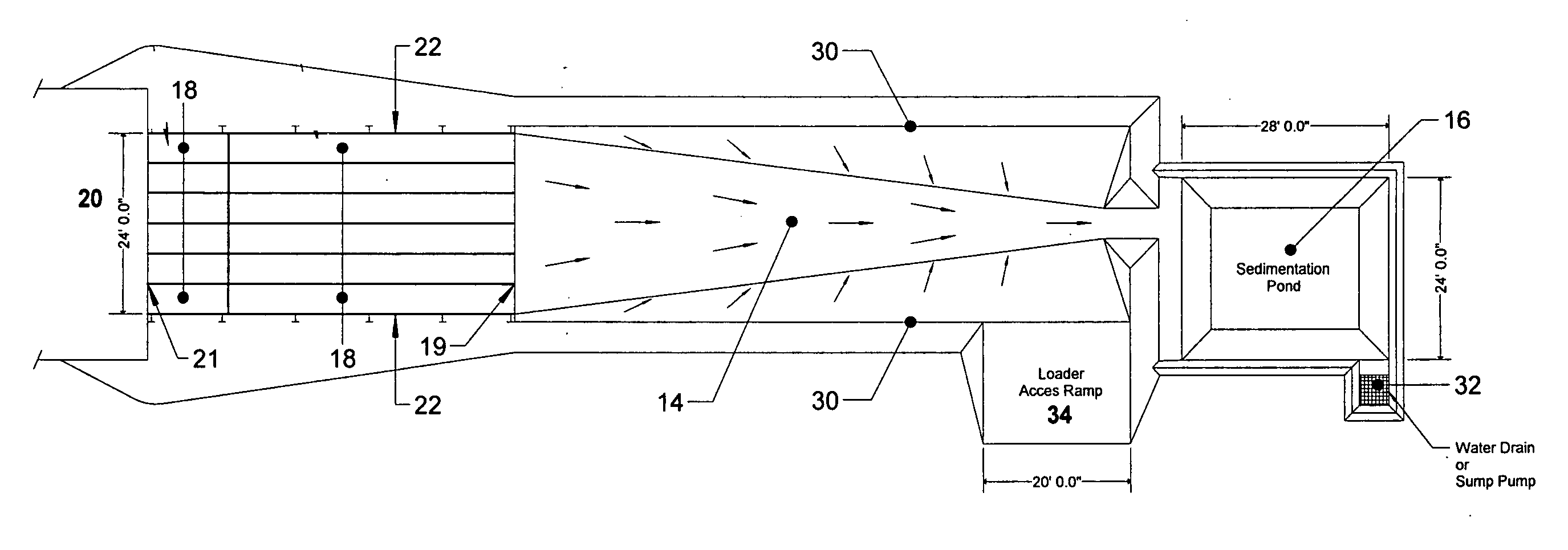

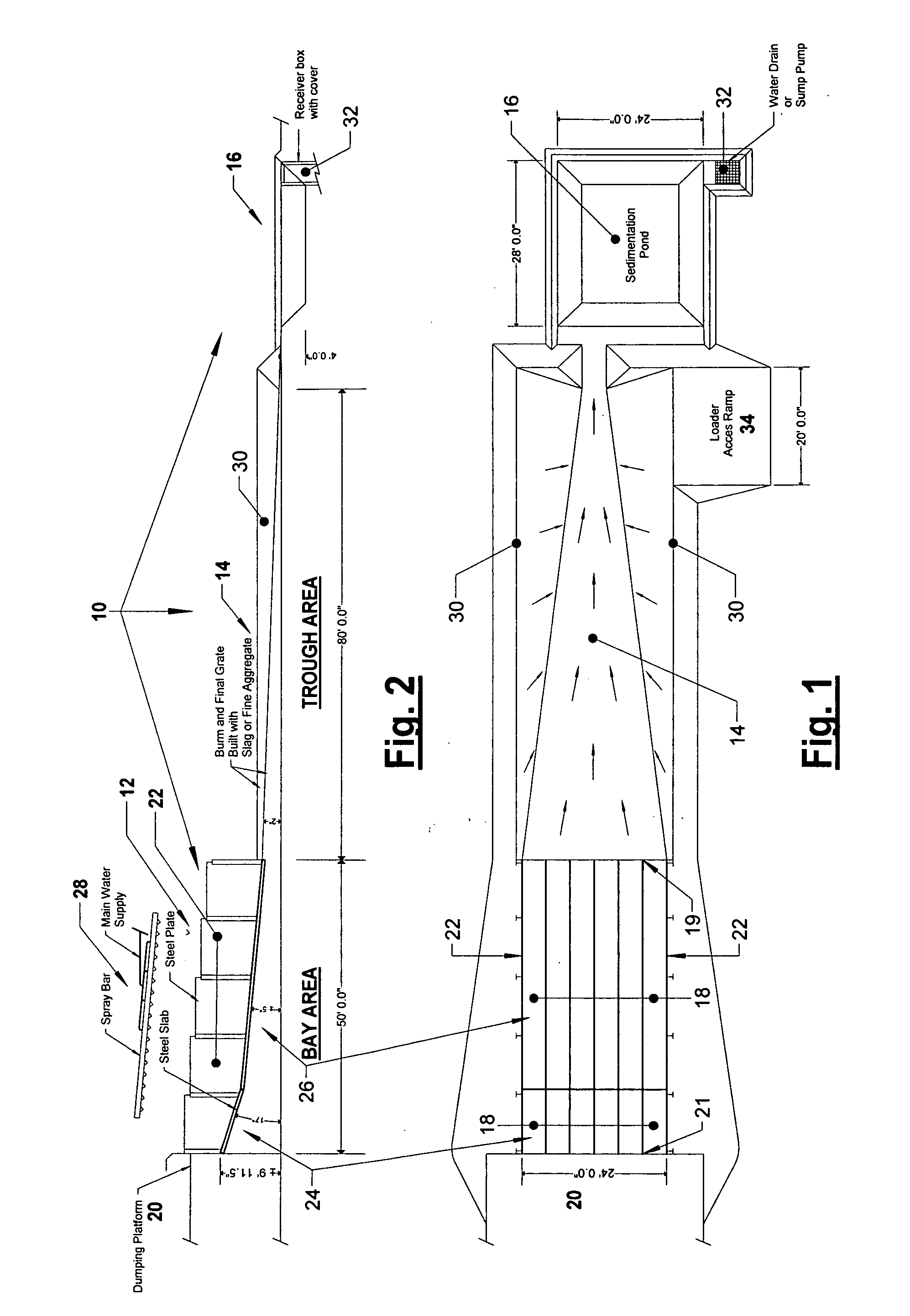

[0023] Referring to FIGS. 1-2, an exemplary apparatus for quick quenching liquid, or molten, slag is illustrated, shown generally at 10. The apparatus 10 generally includes a bay area 12 and a trough area 14. The liquid slag is cooled in the bay area 12 by the application of water under pressure, such that the cooled slag remains in the bay area 12. The trough area 14 receives the water running from the bay area 12 and directs it to a sedimentation pond 16, where the water can be recycled for further quenching or other applications.

[0024] The bay area 12 generally includes a plurality of steel slabs 18 which are installed side by side to form a flat surface. Liquid slag (not shown) is poured onto the steel slabs 18 for cooling, and thus the steel slabs 18 need to be able to withstand the high temperature of the liquid slag. The steel slabs 18 are oriented generally at an angle, with the low end 19 adjacent the trough area 14, such that the liquid slag and the water applied to the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| angle of inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com