Method and arrangement for cooling an exhaust system

a technology for exhaust systems and cooling systems, applied in exhaust treatment, electrical control, mechanical equipment, etc., can solve the problems of evaporative emissions, gas vaporization, engine heat loss, etc., and achieve the effect of reducing evaporative emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

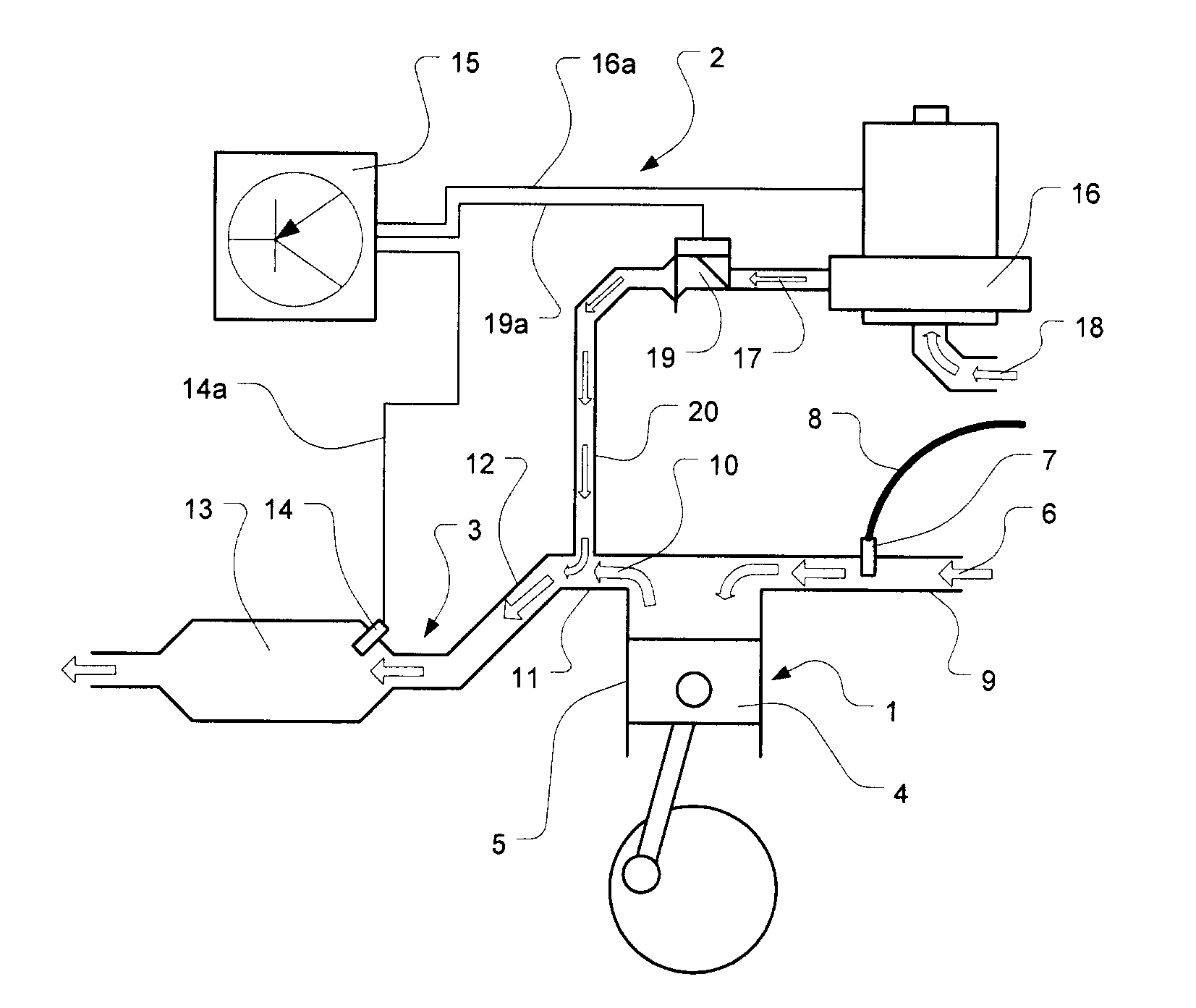

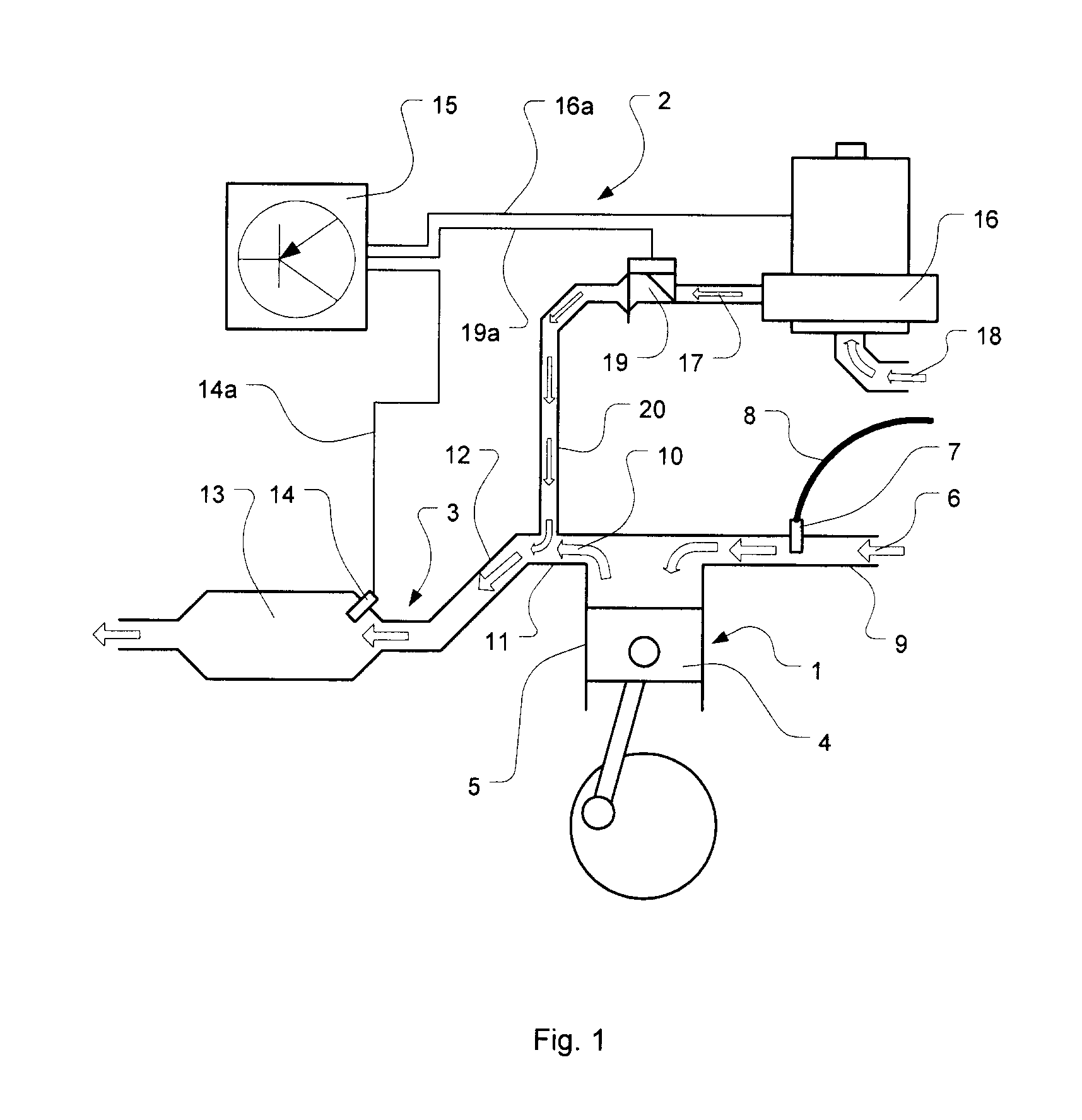

[0018]Referring to FIG. 1, there is illustrated schematically a simplified view of an internal combustion engine 1 having an arrangement 2 for cooling an associated exhaust system 3 in accordance with an embodiment of the present invention. A piston 4 is shown arranged within a cylinder 5 of the engine 1 in conventional manner. Fuel is injected into an air stream, illustrated by arrows 6, by means of a fuel injector 7 and its associated hosing 8. The fuel is injected into the air stream 6 inside an inlet manifold 9 of the engine 1 and mixes with the air stream 6, where after the air / fuel mixture in the inlet manifold 9 is introduced into the cylinder 5 by means of one or more inlet valves, not shown, in conventional manner. Following compression of the air / fuel mixture by the piston 4 the mixture is ignited to drive the piston 4 in conventional manner. Thereafter the produced exhaust gases, illustrated by arrows 10, are allowed to leave the cylinder by means of one or more exhaust v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com