Liquid chemical supply system

a technology of liquid chemical supply and liquid chemical, which is applied in the direction of positive displacement liquid engine, pump parameter, piston pump, etc., can solve the problem that liquid chemical may no longer be able to be discharged as intended, and achieve the effect of accurate detection, high degree of accuracy and high degree of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

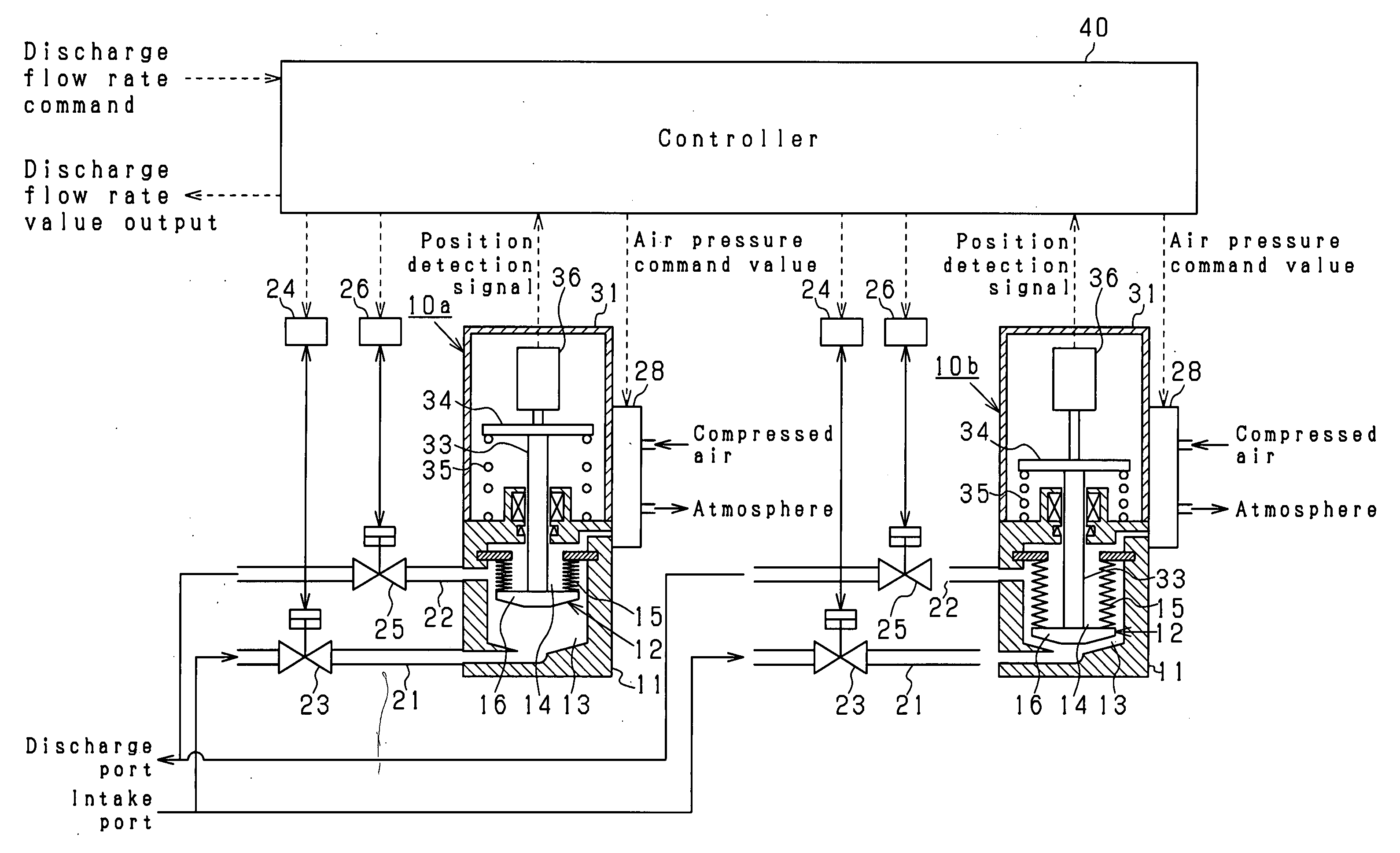

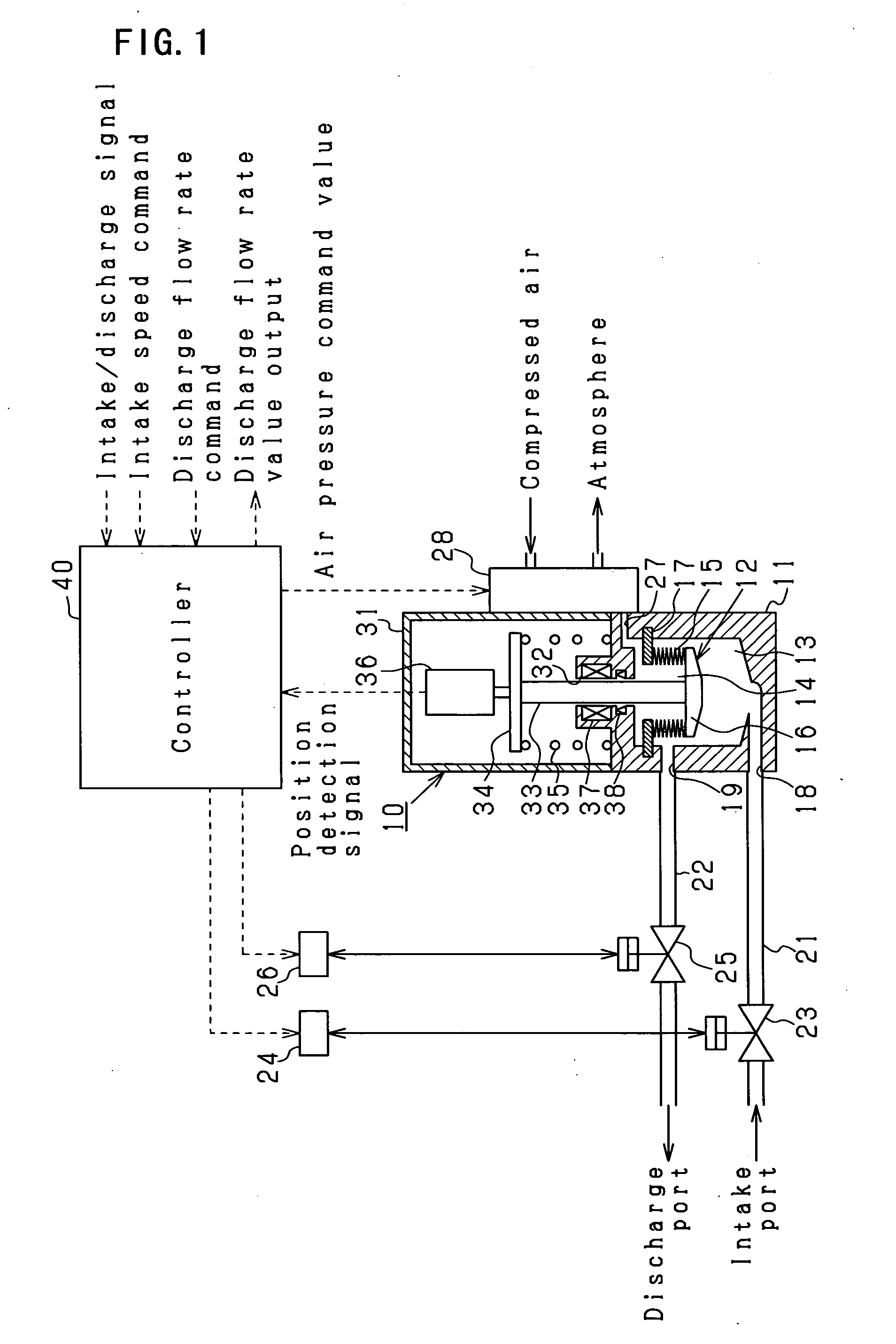

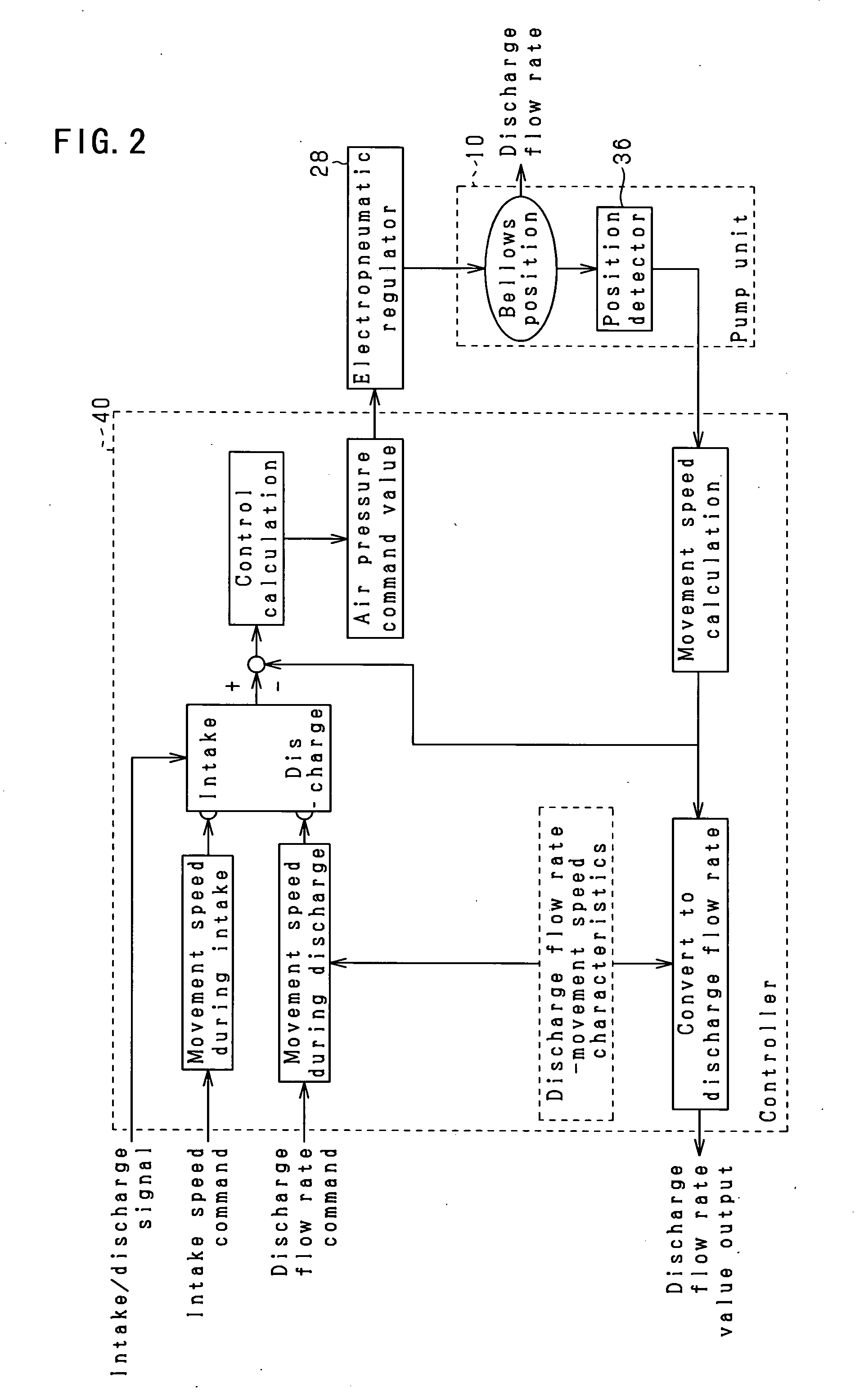

[0039]A first embodiment of the present invention will be described below in accordance with the drawings. The present embodiment is embodied as a liquid chemical supply system which is used in a production line of a semiconductor device or the like. The basic construction of this system will be described based upon FIG. 1.

[0040]The liquid chemical supply system of FIG. 1 comprises a liquid chemical pump 10 for performing the intake and discharge of liquid chemical. A bellows-type diaphragm 12 as a volume variation member is housed inside a pump housing 11 of the liquid chemical pump 10. A pump chamber 13 and a pressure application chamber 14 are separately formed by means of the bellows-type diaphragm 12. The bellows-type diaphragm 12 has a bellows 15 that is compressible in the axial direction, and a diaphragm plate 16 that is attached to one end of the bellows 15 (the lower end in the drawing), and the other end of the bellows 15 (the upper end in the drawing) is fixed to an annu...

second embodiment

[0083]In the aforementioned embodiment, the air pressure was changed by the electropneumatic regulator 28 with the pump chamber 13 sealed in the liquid chemical pump 10, and an air intrusion determination was performed based upon the amount of extension or contraction of the bellows at that time. However, in the second embodiment, the aforementioned method is changed with respect to the air intrusion determination. In other words, in the present embodiment, after first opening the intake valve 23 in order to perform intake, the air pressure will be controlled with the electropneumatic regulator 28, and the bellows type diaphragm 12 will be displaced while resisting the urging force of the compression coil spring 35. Next, the pump chamber 13 will be sealed, and the air pressure control by the electropneumatic regulator 28 will be released in this state. Then, an air intrusion determination will be performed based upon the change in the bellows length at that time.

[0084]A summary of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com