High temperature lubricant compositions

a technology of lubricant composition and high temperature, applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of increasing the viscosity of lubricant, reducing the mobility of lubricant liquid, and formation of deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

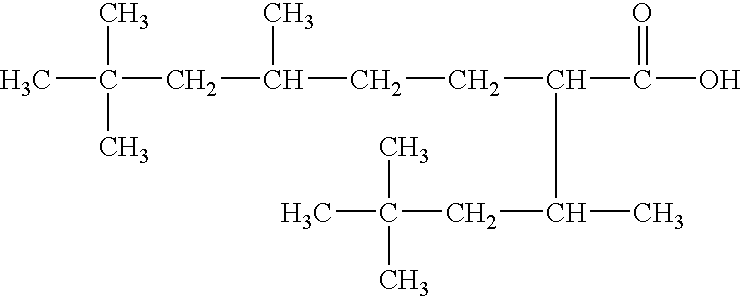

[0037]The lubricant composition trimethylolpropane tri-5,7,7-trimethyl-2-(1,3,3-trimethylbutyl)-octanoate (TMPTTBO) was prepared by combining the following materials of Table 1 in a batch reactor fitted with a mechanical stirrer, inert gas sparge, vapor column, condenser, and distillate receiver. Pressure in the reactor was controlled by a vacuum pump that was attached to the reactor.

TABLE 1Parts Per 100Moles Per 100ComponentPartsPartsTrimethylolpropane13.60.1015,7,7-trimethyl-2-(1,3,3-trimethylbutyl)-86.40.304octanoic acid

[0038]About 0.10 parts per 100 parts tetrabutyltitanate was added to the reaction mixture, and the mixture was heated to from about 180° C. to about 250° C. Pressure was slowly reduced until sufficient conversion was obtained. The crude ester was further purified by steam distillation and filtration. The result was a yellow viscous liquid possessing the following properties shown in Table 2:

TABLE 2Property, UnitsTest MethodResultTotal Acid Number, mg KOH / gASTM D-9...

example 2

[0039]The lubricant composition Trimethylolpropane / Pentaerythritol 5,7,7-trimethyl-2-(1,3,3-trimethylbutyl)-octanoate (TMPPETTBO) was prepared by combining the following materials in Table 3 in a batch reactor fitted with a mechanical stirrer, inert gas sparge, vapor column, condenser, and distillate receiver. Pressure in the reactor was controlled by a vacuum pump that was attached to the reactor.

TABLE 3Parts Per 100Moles PerComponentParts100 PartsTrimethylolpropane9.50.071Pentaerythritol3.20.0245,7,7-trimethyl-2-(1,3,3-trimethylbutyl)-87.30.307octanoic acid

[0040]About 0.10 parts per 100 parts tetrabutyltitanate was added to the reaction mixture, and the mixture was heated to from about 180° C. to about 250° C. The pressure was slowly reduced until sufficient conversion was obtained. The crude ester was further purified by steam distillation and filtration. The result was a yellow viscous liquid possessing the following properties listed in Table 4:

TABLE 4Property, UnitsTest Method...

example 3

[0041]A lubricant base oil was prepared by combining the following ingredients of Table 5:

TABLE 5ComponentParts Per 100 PartsTMPTTBO50Synthetic Ester50

[0042]The result was a yellow viscous liquid possessing the following properties shown in Table 6:

TABLE 6Property, UnitsTest MethodResultTotal Acid Number, mg KOH / gASTM D-9720.17Hydroxyl Number, mg KOH / gASTM D-19574.5Kinematic Viscosity @ 40° C., cStASTM D-445401.4Kinematic Viscosity @ 100° C., cStASTM D-44520.0Viscosity IndexASTM D-227035Flash Point (C.O.C), ° C.ASTM D-92270Pour Point, ° C.ASTM D-97−15Evaporation Loss, %58.7Deposits After Heating, VisualMinimalFluidity After Heating, VisualFluid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com