Refrigeration cycle device

a technology of refrigerating cycle and condenser, which is applied in the direction of lighting and heating apparatus, heating types, and domestic hot water supply systems, etc., can solve the problems of deteriorating cooling capacity of evaporators, shortening or lowering the amount of heat to be rejected from refrigerant in the condenser, and causing temperature rise, so as to maintain the cooling capacity of the evaporator, the temperature of the water subjected to the heat exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

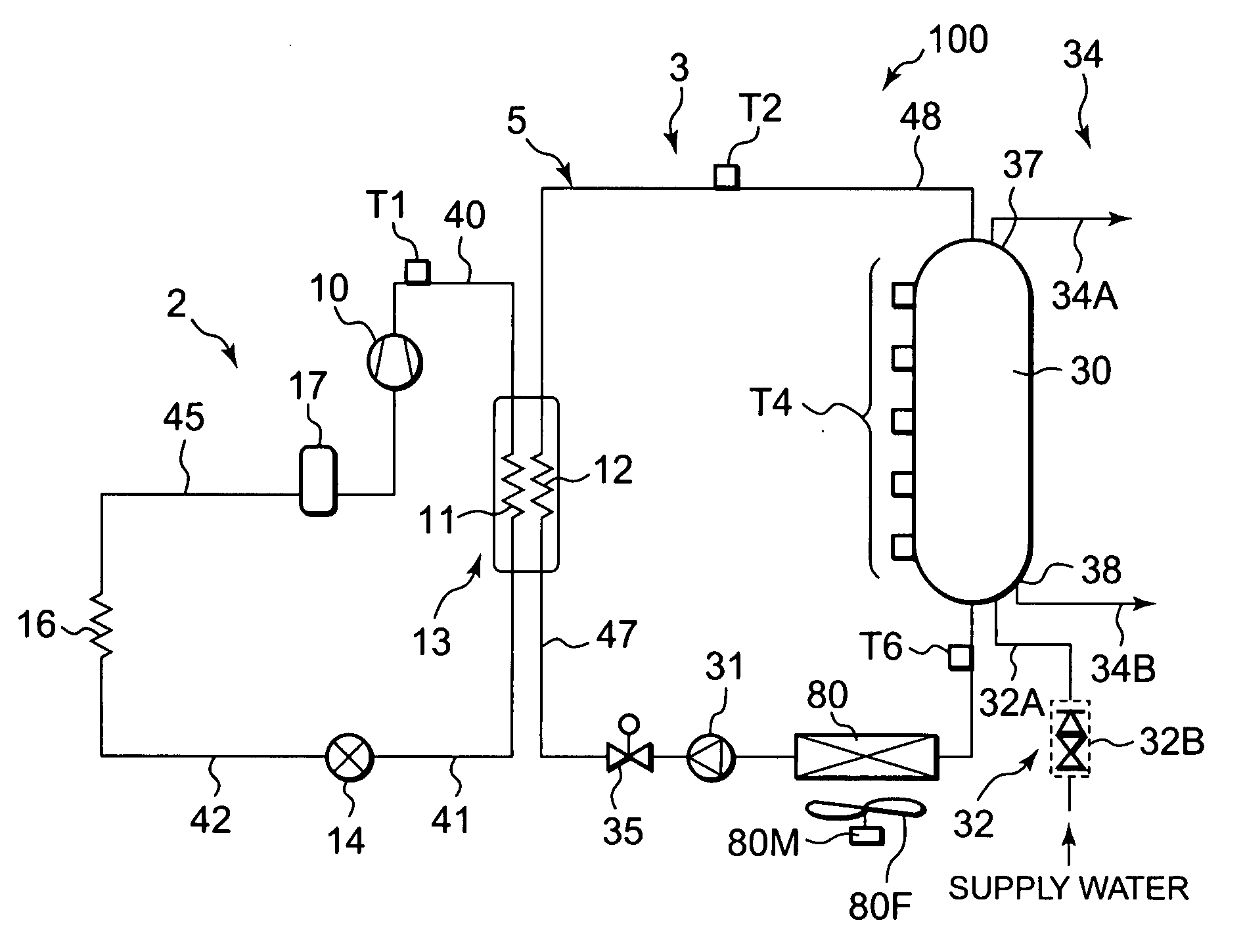

[0027]FIG. 1 is a schematic constitution diagram of a refrigeration cycle device of one embodiment to which the present invention is applied. A refrigeration cycle device 1 of the present embodiment is provided with a refrigerant circuit 2 including a compressor 10, a condenser 11, an expansion valve 14 as a throttling means and an evaporator 16; and a hot water supply circuit 3 including a hot water storage tank 30. The device exhibits a heating function by heat rejected from the condenser 11 and exhibits a cooling function by heat absorption of the evaporator 16. That is, the refrigeration cycle device 1 performs heat exchange between water or hot water circulated from the hot water storage tank 30 through the hot water supply circuit 3 and the condenser 11 to generate high-temperature water by the heat rejected from the condenser 11 and store the hot water in the hot water storage tank 30. Moreover, the device exhibits the cooling function by the heat absorption of the evaporator...

embodiment 2

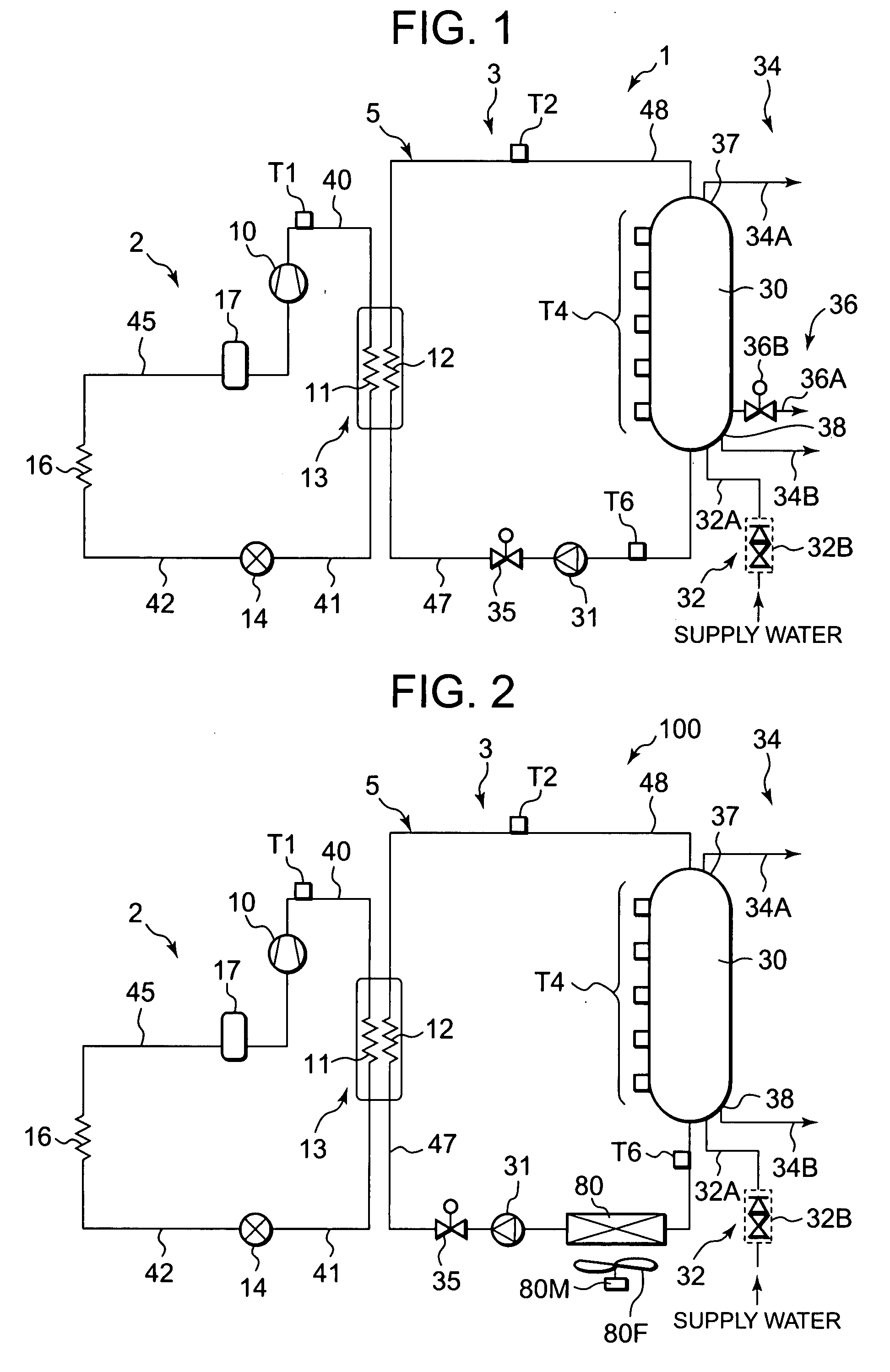

[0077]Next, another embodiment of a refrigeration cycle device according to the present invention will be described. FIG. 2 is a schematic constitution diagram of the refrigeration cycle device of the embodiment to which the present invention is applied. In FIG. 2, components denoted with the same reference numerals as those of FIG. 1 are the same components or components which produce similar functions or effects. Therefore, description thereof is omitted, and a part of the present embodiment different from the above embodiment will mainly be described.

[0078]First, a difference between a constitution of a refrigeration cycle device 100 of the present embodiment and that of the refrigeration cycle device 1 of Embodiment 1 will be described. The refrigeration cycle device 1 of Embodiment 1 includes a discharge unit 36 which discharges hot water from a hot water storage tank 30 as needed. On the other hand, the refrigeration cycle device 100 of the present embodiment does not include ...

embodiment 3

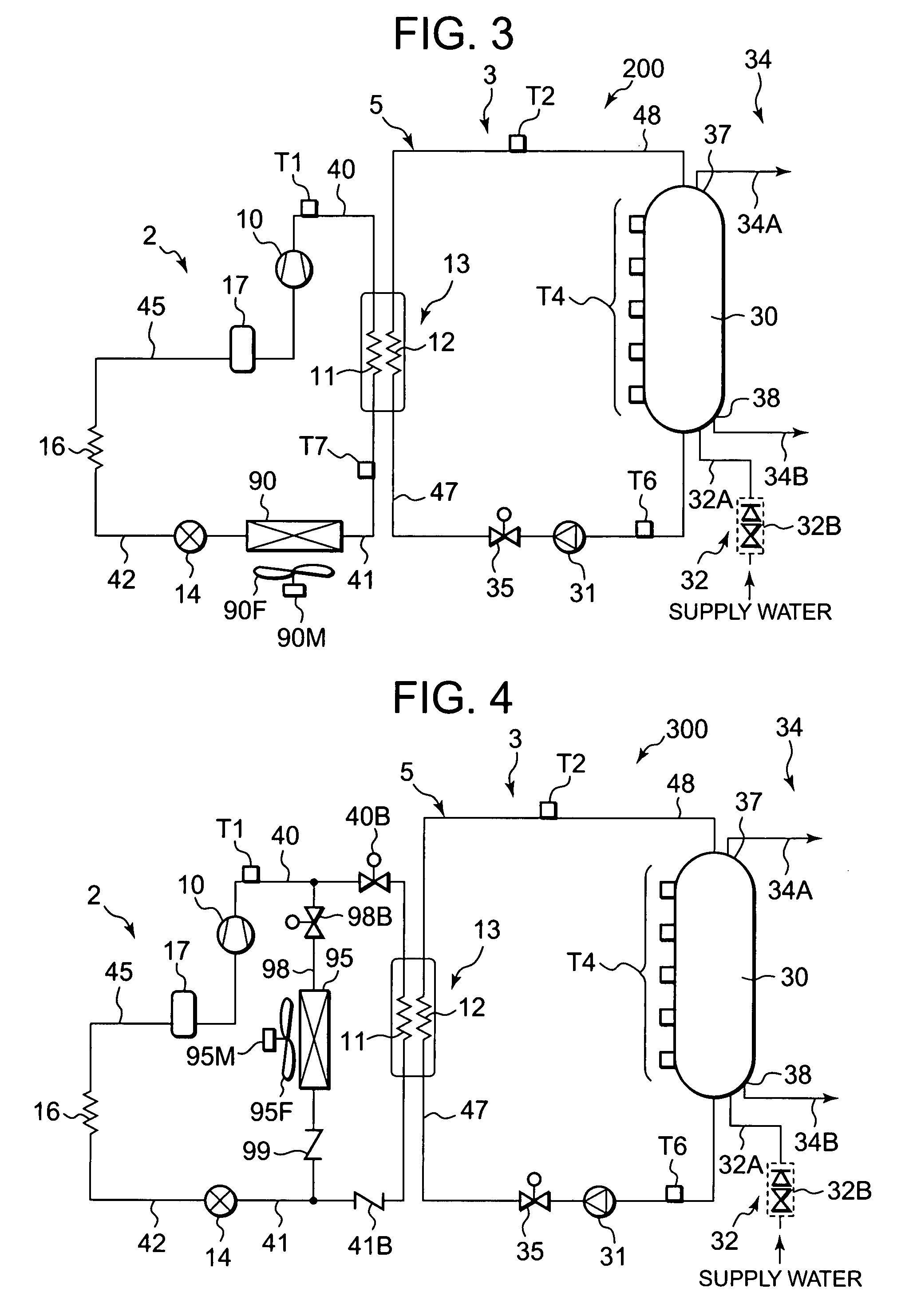

[0093]Next, still another embodiment of a refrigeration cycle device according to the present invention will be described. FIG. 3 is a schematic constitution diagram of the refrigeration cycle device of Embodiment 3 to which the present invention is applied. It is to be noted that in FIG. 3, components denoted with the same reference numerals as those of FIGS. 1 and 2 are the same components or components which produce similar functions or effects. Therefore, description thereof is omitted, and a part of the present embodiment different from the above embodiments will mainly be described.

[0094]First, a difference between a constitution of a refrigeration cycle device 200 of the present embodiment and that of the refrigeration cycle device 1 of Embodiment 1 will be described. The refrigeration cycle device 1 of Embodiment 1 includes a discharge unit 36 which discharges hot water from a hot water storage tank 30 as needed. On the other hand, the refrigeration cycle device 200 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com