Evaporatively cooled thermosiphon

a technology of thermosiphon and cooling assembly, which is applied in the direction of heat exhanger fins, lighting and heating apparatus, and semiconductor devices, etc., can solve the problems of air having a relatively low heat capacity and the ability of cooling units to effectively disperse heat, so as to increase the surface area, enhance the heat transfer rate, and increase the heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

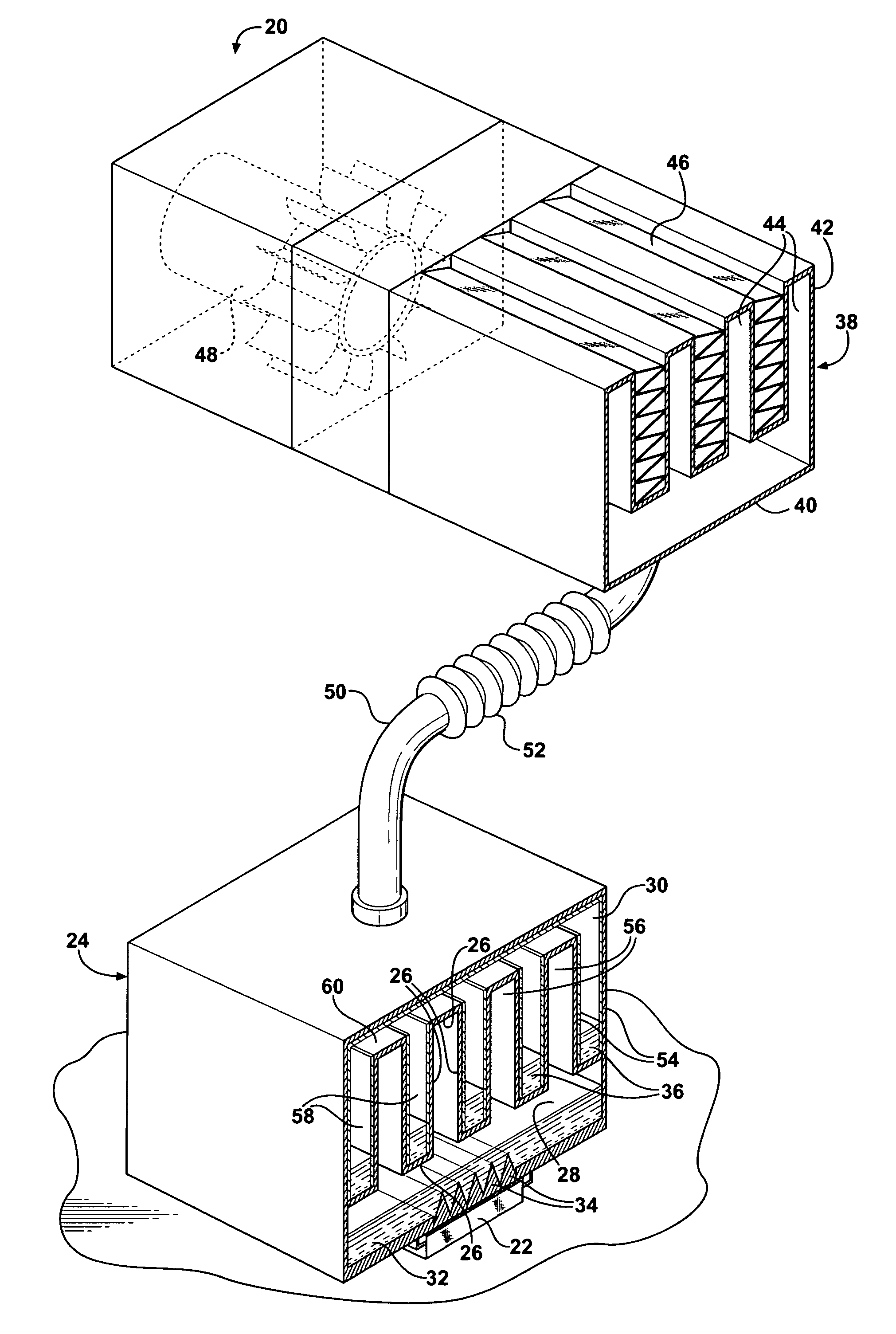

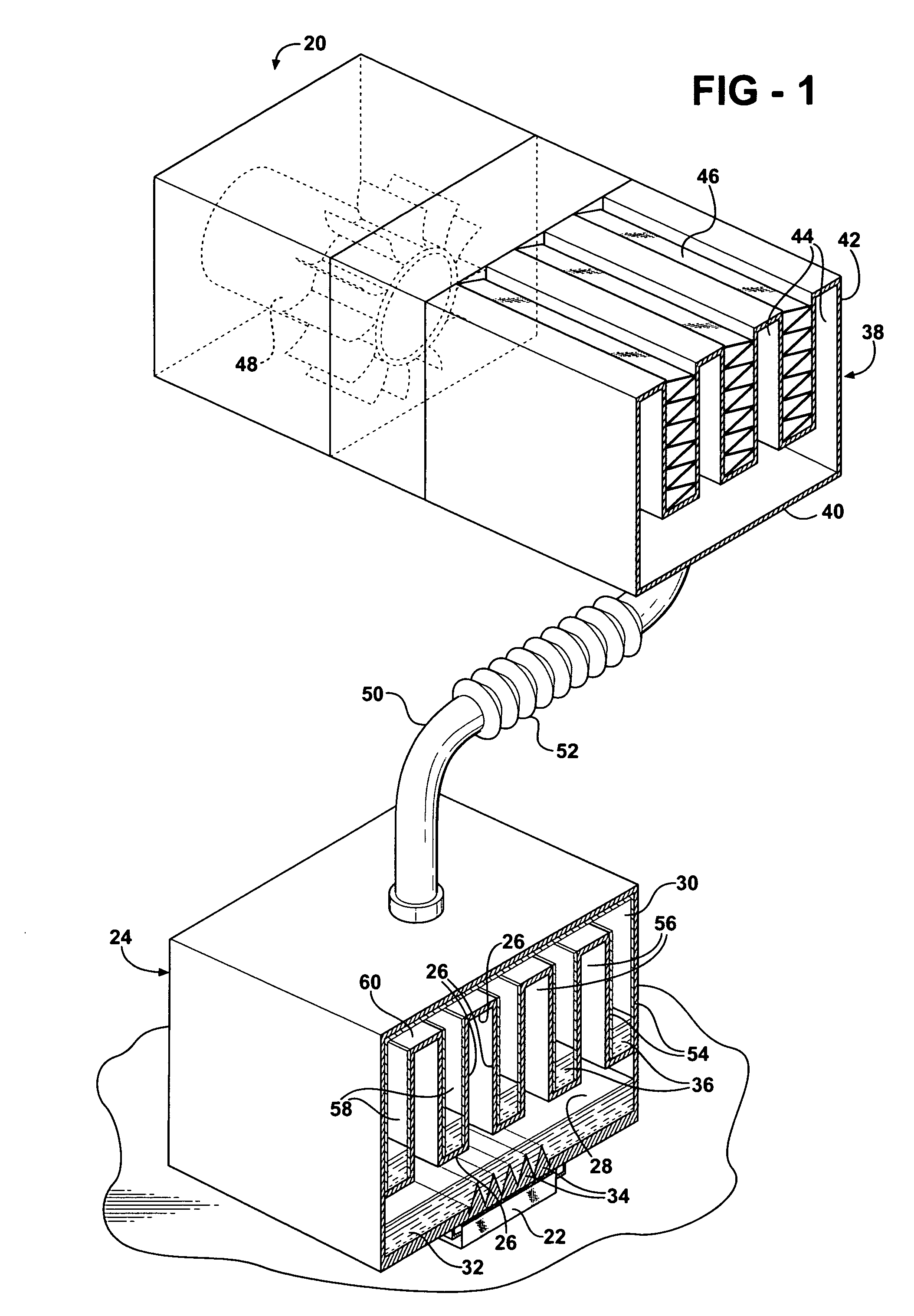

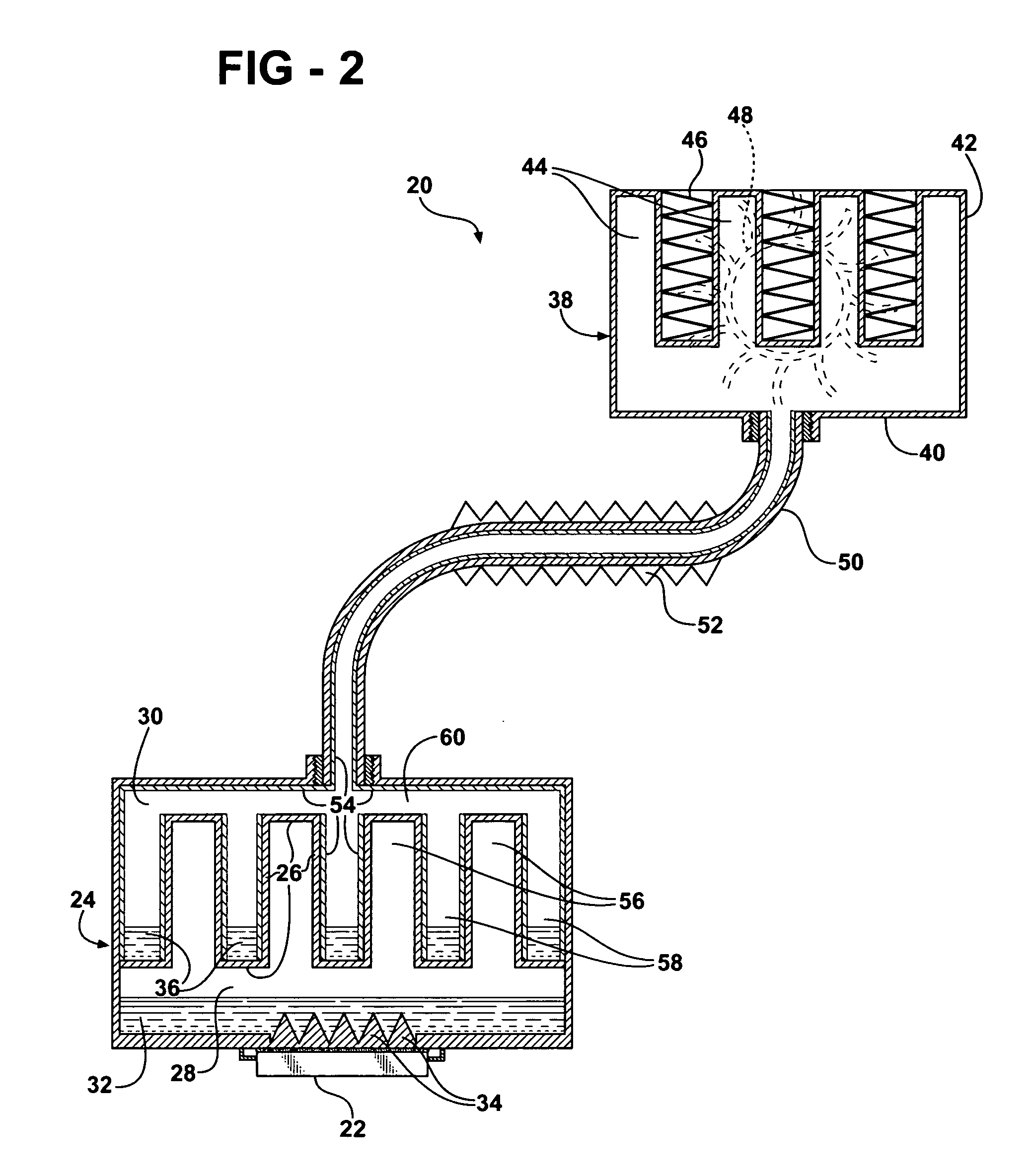

[0017] Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a thermosiphon cooling assembly 20 is shown generally for cooling an electronic device 22.

[0018] A thermosiphon cooling assembly 20 comprises a housing 24 generally indicated having a partition 26 defining a lower boiling chamber 28 for receiving heat from the electronic device 22 and an upper evaporating chamber 30. The assembly 20 is used to cool the electronic device 22 engaging or secured to the exterior of the lower boiling chamber 28 of the housing 24. The housing 24 is generally rectangular with the lower boiling chamber 28 being hermetically sealed to contain a first refrigerant 32 for liquid-to-vapor transformation.

[0019] The first refrigerant 32 is disposed below the partition 26 in the lower boiling chamber 28 of the housing 24 for liquid-to-vapor transformation. The first refrigerant 32 is confined to the lower boiling chamber 28 of the housing 24 and absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com