Device for generating hydrogen for use in internal combustion engines

a technology for internal combustion engines and hydrogen, which is applied in the field of fuel in internal combustion engines, can solve the problems of increasing fuel cost, affecting the economy of most drivers, and requiring a large amount of environmental cost, so as to reduce the amount of fuel an internal combustion engine consumes, increase the efficiency of the internal combustion engine, and reduce the effect of hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

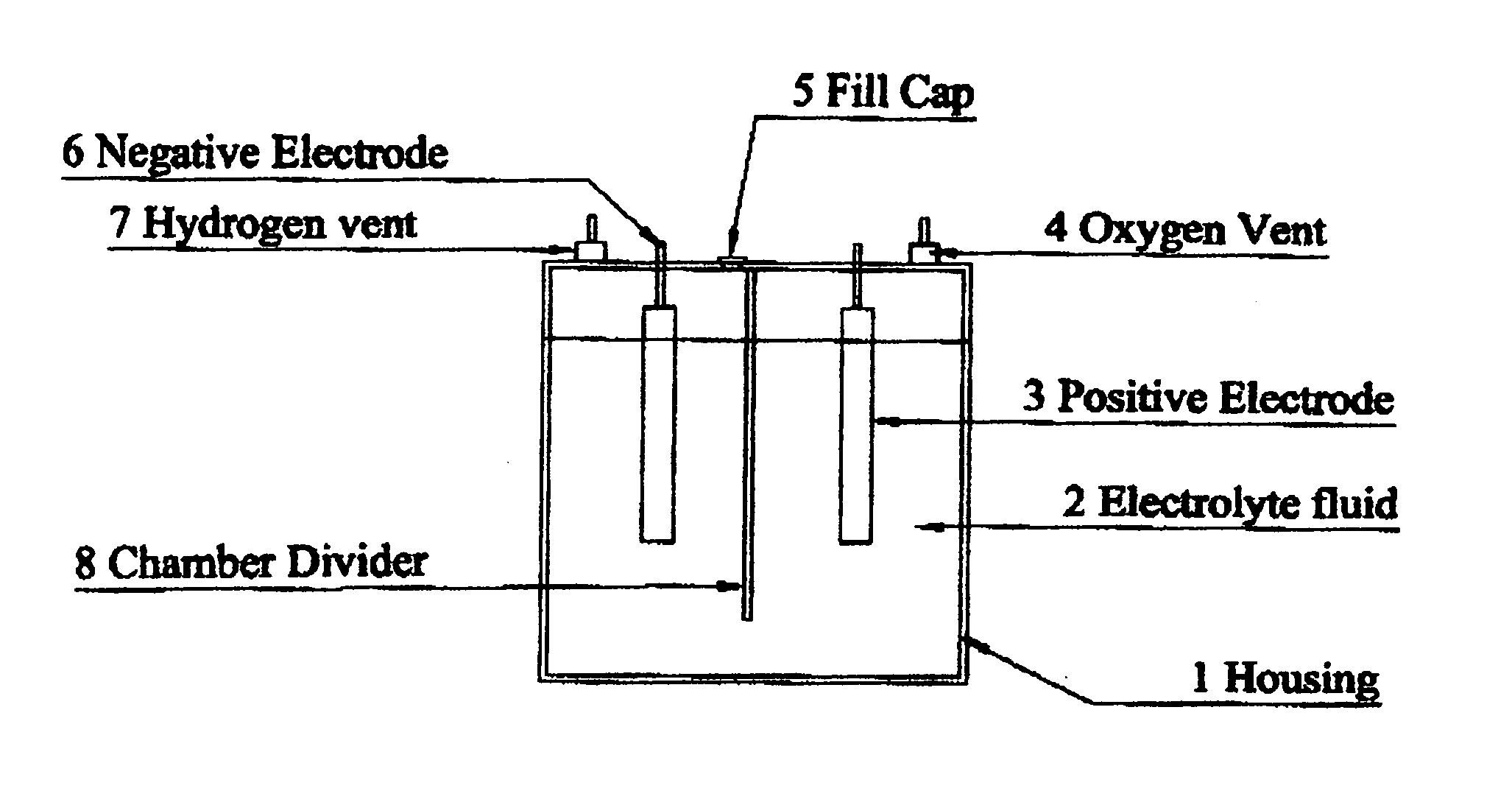

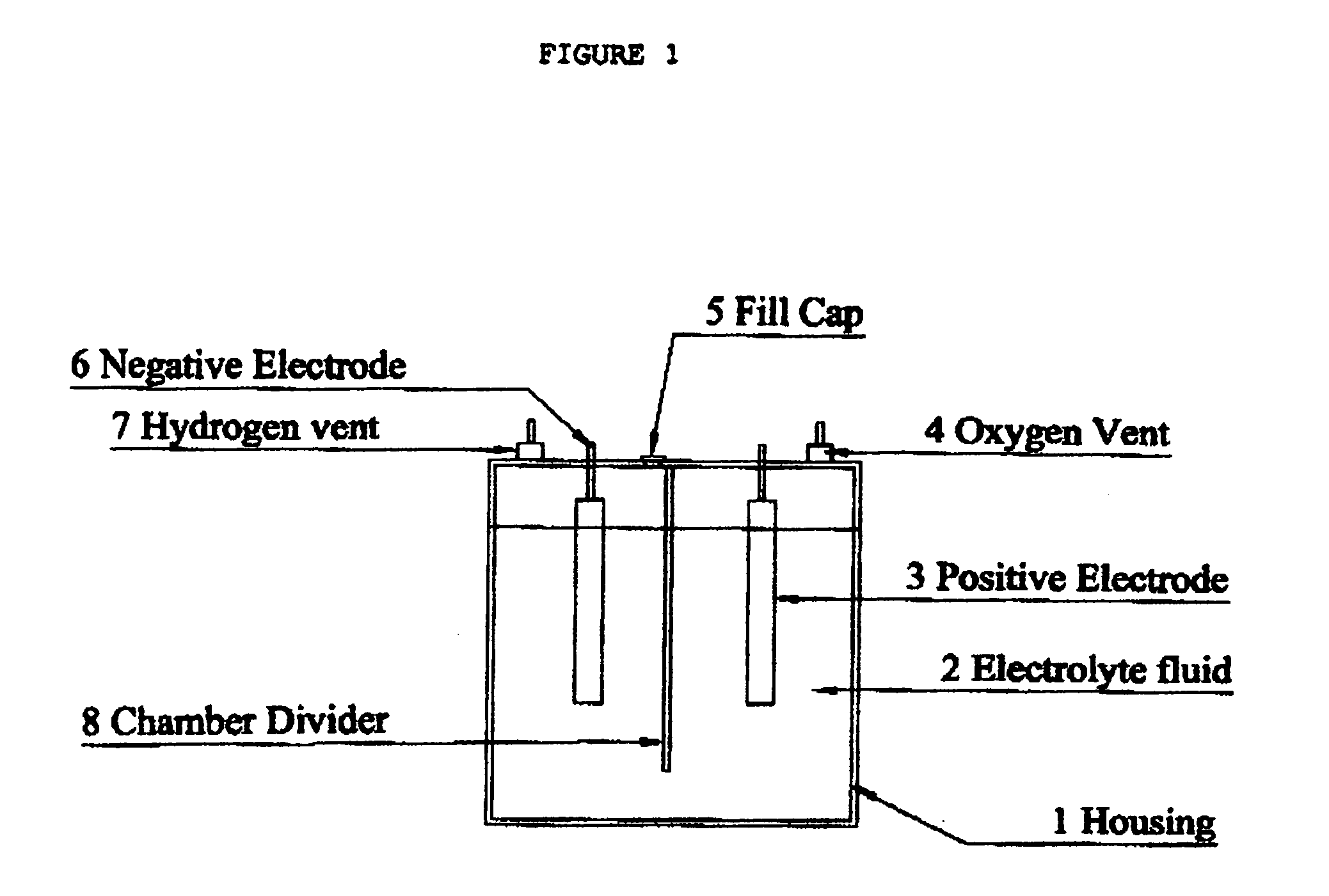

[0023]FIG. 1 which is a front view of the housing 1 for the electrodes provides a space to add water and space for the electrode to come in contact with water. The Electrolyte fluid 2 increases the conductivity of the fluid. The Positive Electrode 3 provides a device to bring the positive current in contact with the electrolyte fluid 2. The Oxygen vent (4) provides an exit for the oxygen gas hat is created. The fill cap (5) provides a place to fill the device with the fluid. The Negative Electrode 6 provides a place for the negative current to come in contact with the fluid. The Hydrogen vent 7 provides a exit for the hydrogen gas that is created The Chamber Divider 8 (6) separated the hydrogen from the oxygen.

[0024] Since other modifications and changes varied to fit particular operating requirements and environments will be apparent to those skilled in the art, the invention is not considered limited to the example chosen for purposes of disclosure, and covers all changes and mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| volumes | aaaaa | aaaaa |

| weights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com