Brazing material with continuous length layer of elastomer containing a flux

a technology of elastomer and flux, which is applied in the direction of manufacturing tools, solvents, packaging, etc., can solve the problems of reducing the overall product cost, so as to achieve the effect of preventing, limiting or minimizing cracking, peeling, cracking or detachment, and sufficient elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

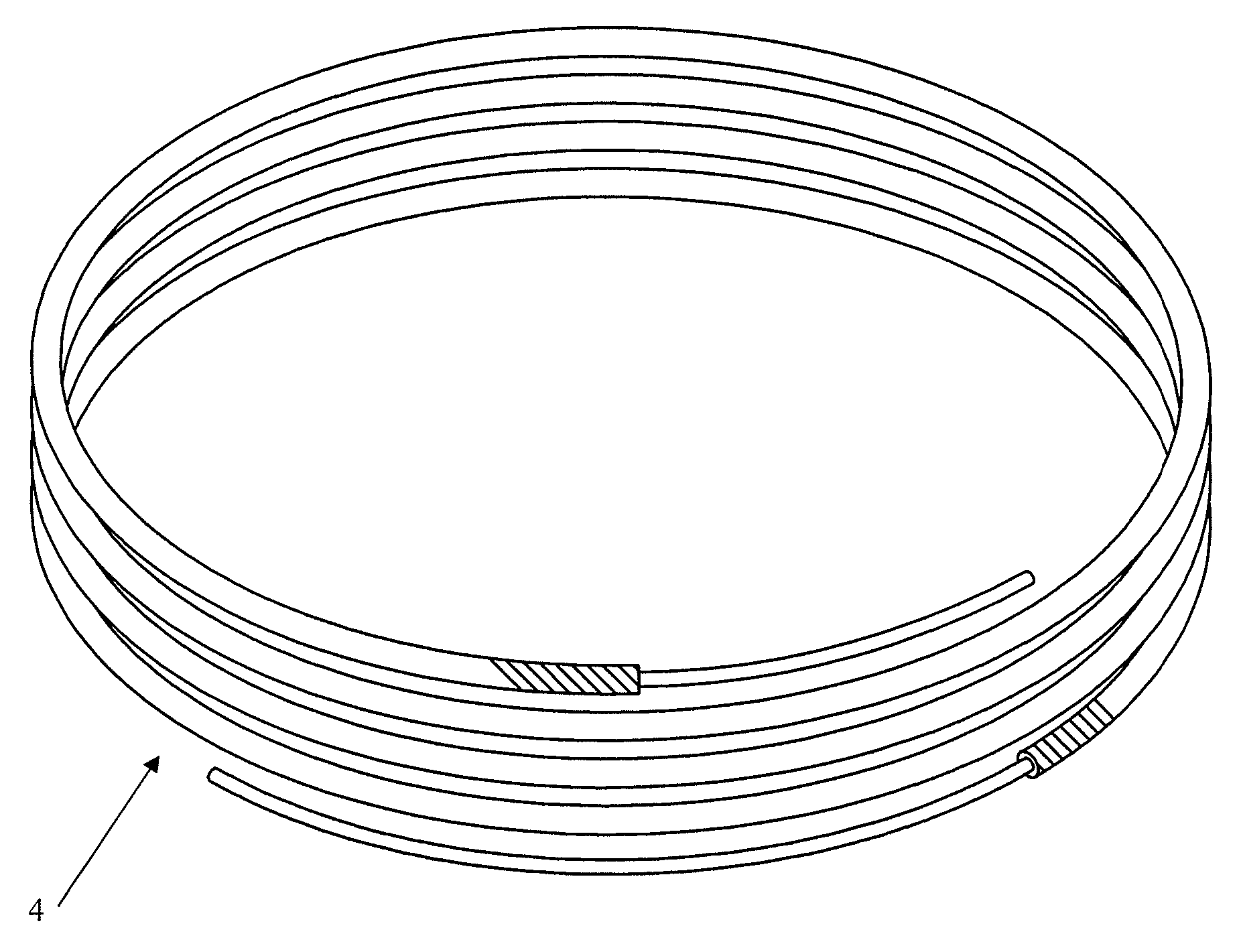

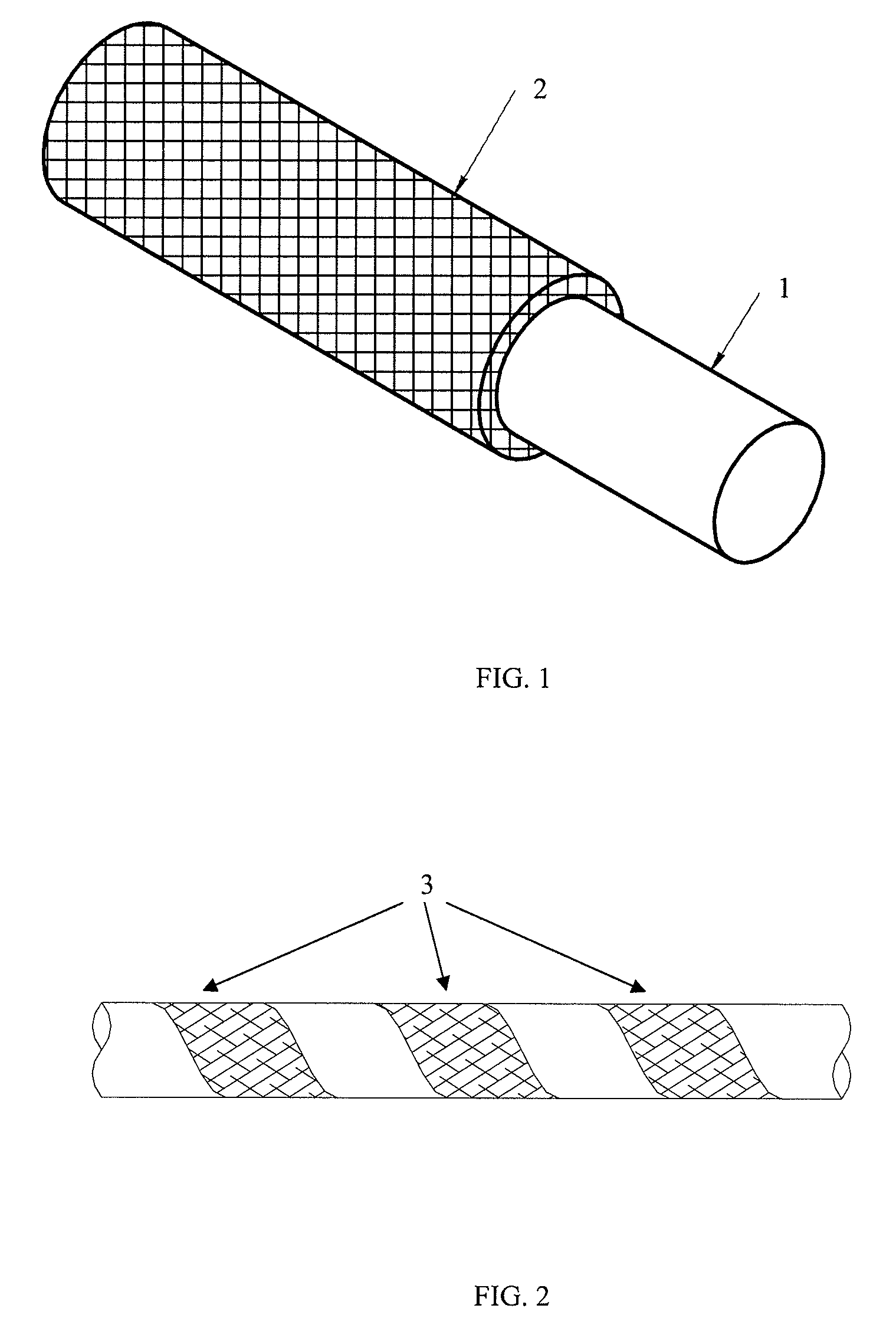

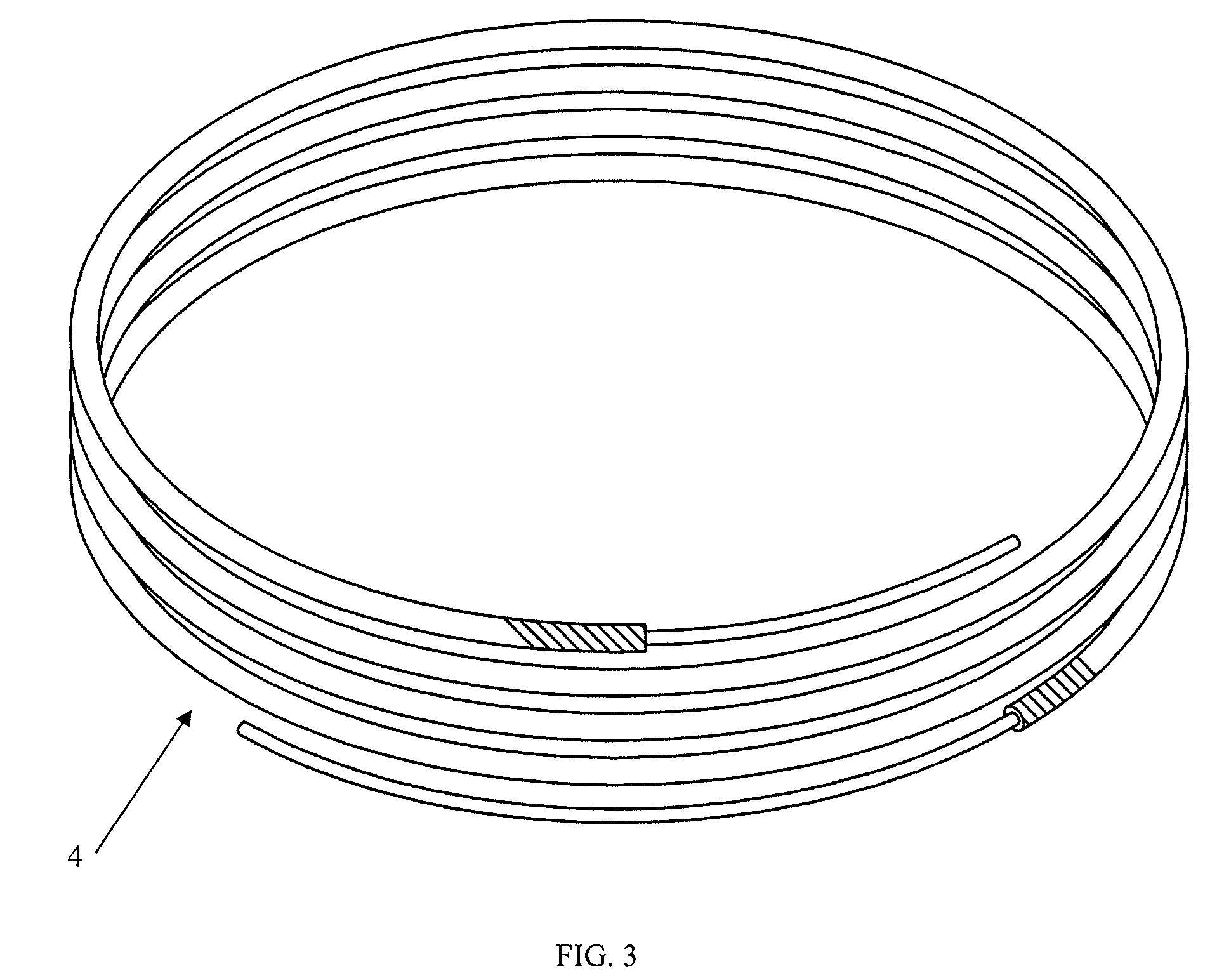

[0037] Applicants have discovered a flux composition suitable for coating or coring a brazing material 1 (when used as either a coating or a coring material the flux is referred to herein as a “flux coating composition”) and that retains both sufficient hardness or toughness (durability) and sufficient flexibility (elasticity) so that the coated or cored brazing material 1 may be bent, conformed, or deformed as needed to enhance the usefulness and effectiveness of the brazing. The flux coating composition 2 of the present invention preferably utilizes a clean burning binder that yields a brazed joint substantially free of impurities or joint contamination.

[0038] Through extensive experimental investigation Applicants have discovered that a flux coating composition 2 should preferably have at least one of the following characteristics or properties: [0039] (a) The elastomer solution (e.g., the elastomer and any solvent used with the elastomer) when mixed with a flux powder or flux p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com