Ice Drill

a drill and ice technology, applied in the field of ice drills, can solve the problems of difficult boring, uncomfortable hits and pulls, and difficult boring, and achieve the effects of improving drilling smoothness, easy and reliable extraction, and easy production of attachments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

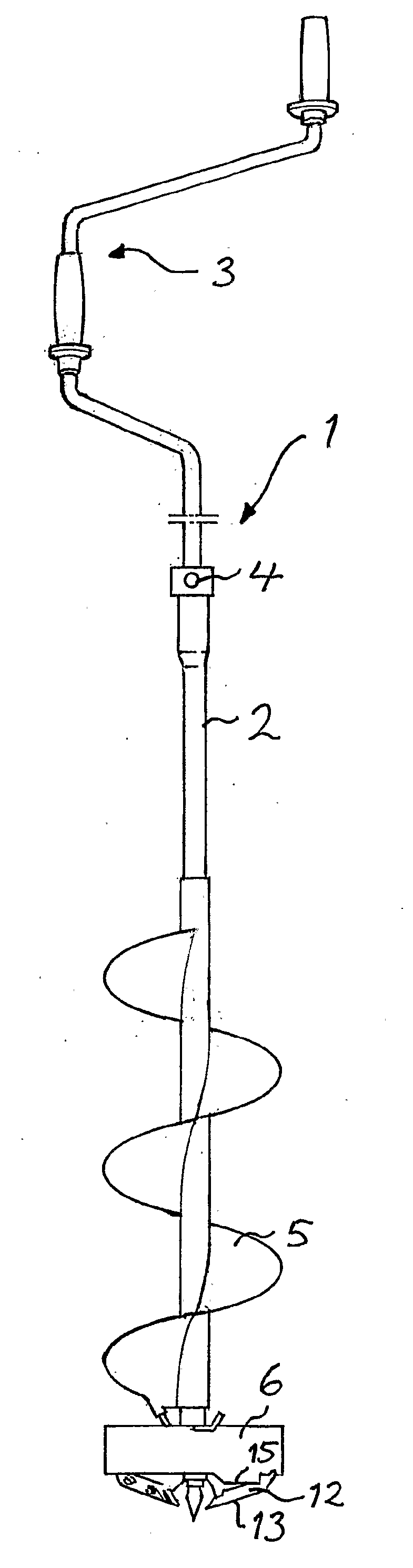

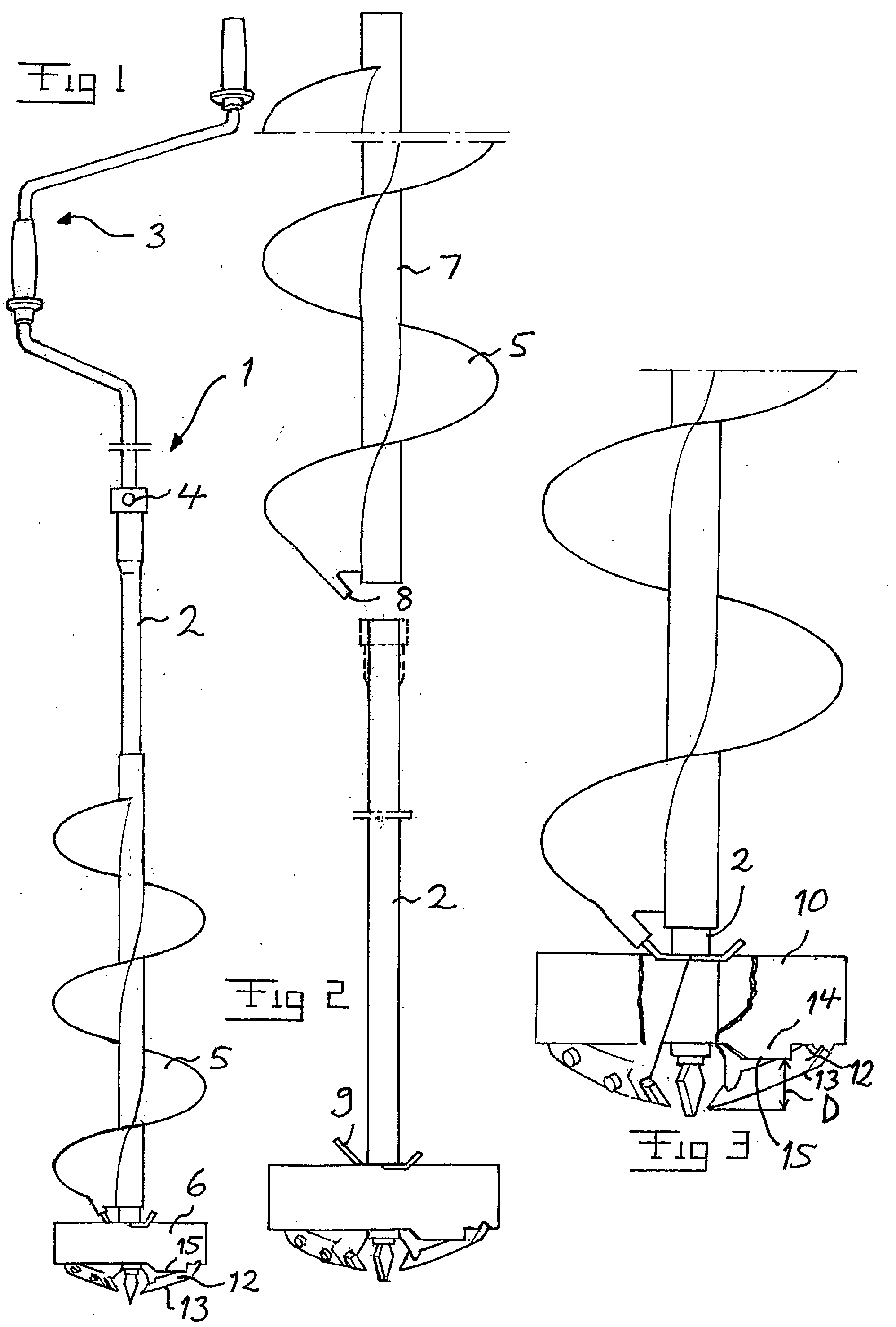

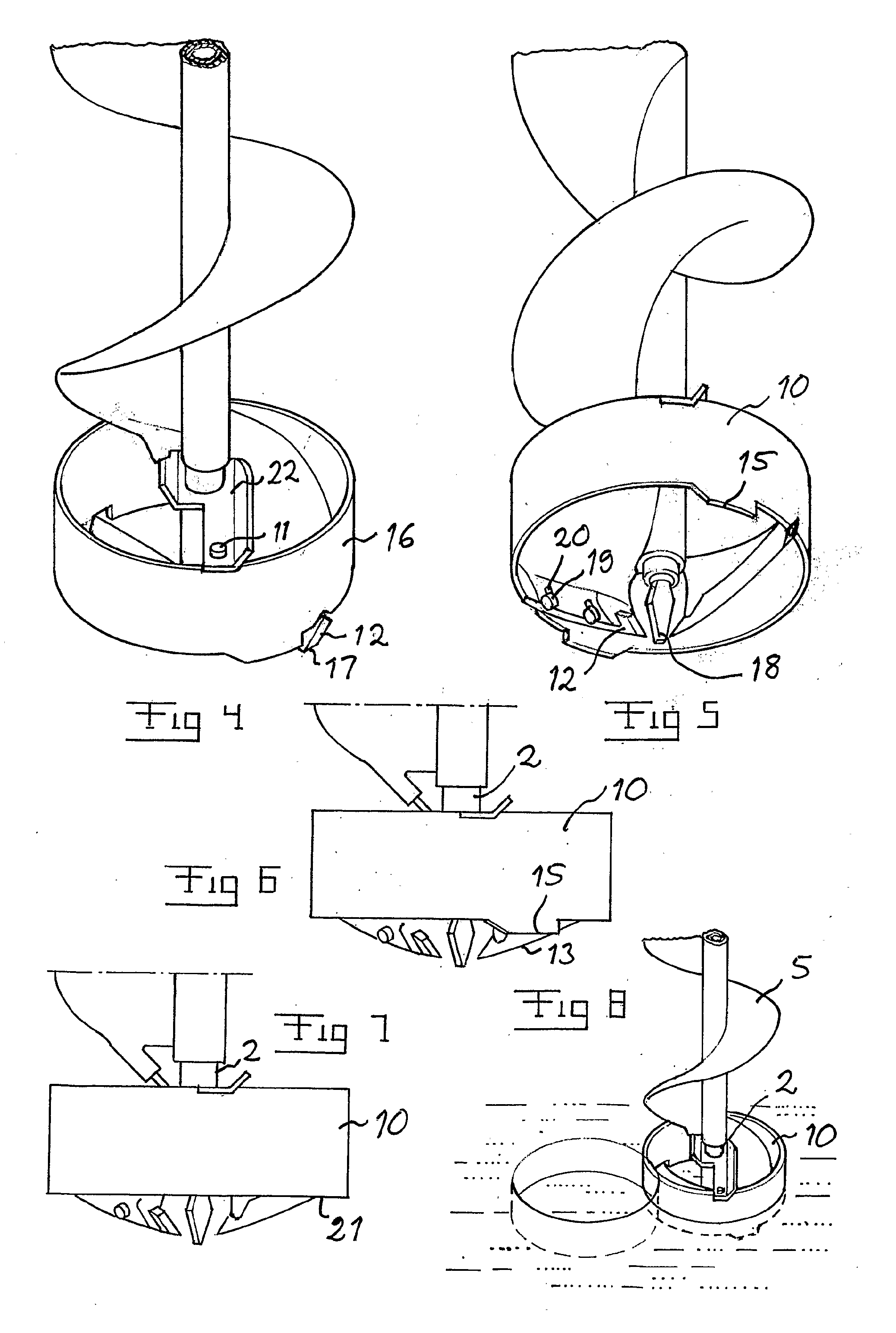

[0031] An ice drill 1 according to an embodiment of the present invention is illustrated in FIG. 1. This has a central rigid drill rod 2, which for example is made of stainless steel or surface treated steel. A crank 3 is removably secure to the drill rod at 4 so as to be able to drive the drill rod 2 to rotate around the axis thereof.

[0032] A spiral 5 extends around the drill rod from the region of a bore crown 6 and upwards for lifting crushed ice formed by the drilling. The spiral 5 is in the present case moulded of plastic material in one single piece with a sleeve 7 central with respect thereto. It is illustrated in FIG. 2 how this piece moulded of plastic is moved onto the drill rod upon manufacturing thereof to the position according to FIG. 1, where a recess 8 in the spiral receives a projection 9 extending from the drill rod and the spiral is then shrank onto the drill rod 2. By the manufacture of the spiral 5 in this way of plastic material it gets an advantageous very lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com