Method for forming a container with corrugated wall and rolled lip

a corrugated paper and container technology, applied in the field of corrugated paper containers, can solve the problems of limiting the commercial feasibility of this approach, not biodegradable, easy to be recycled or microwavable, and provide little thermal insulation, so as to reduce the tearing of the rim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

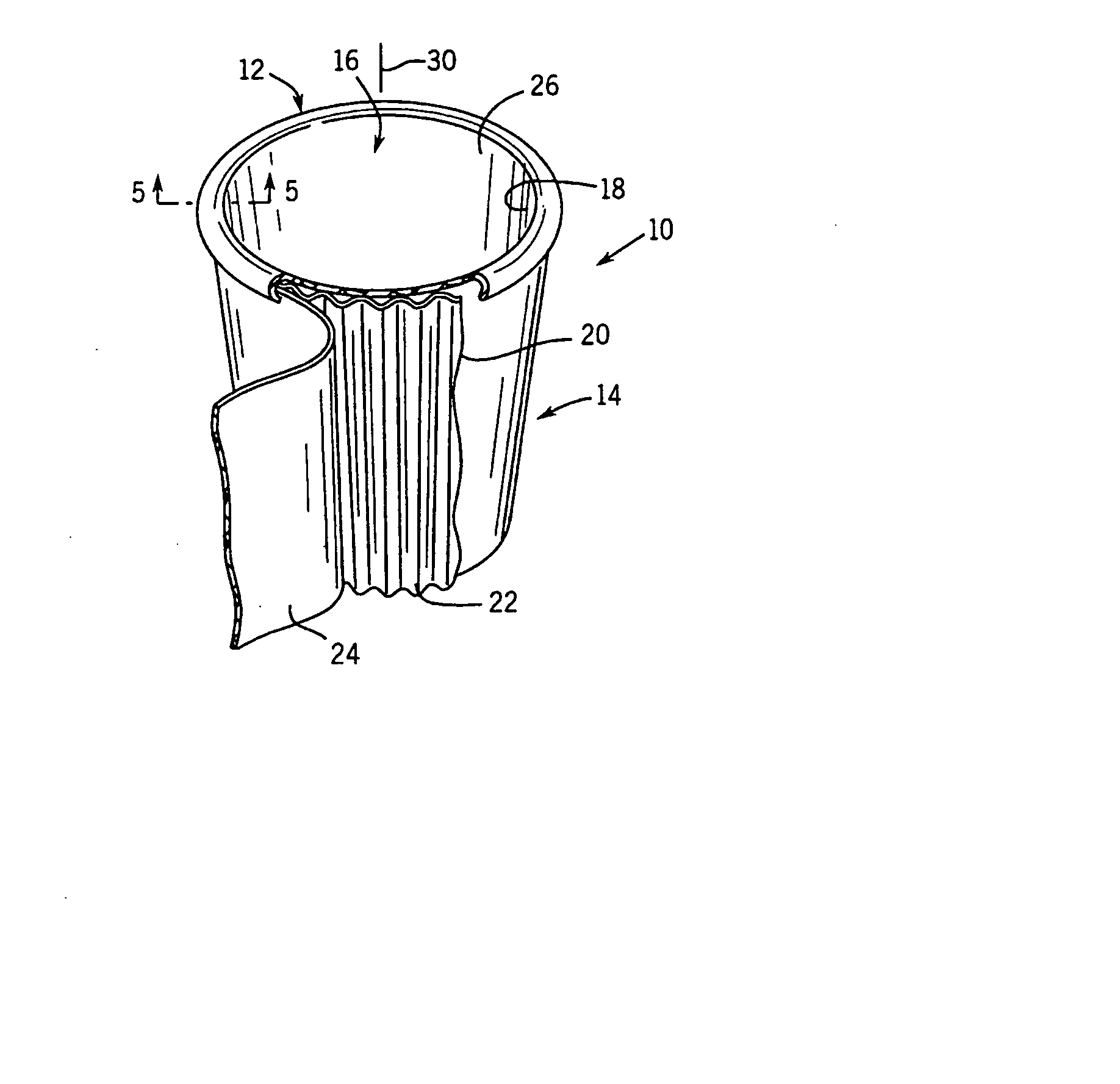

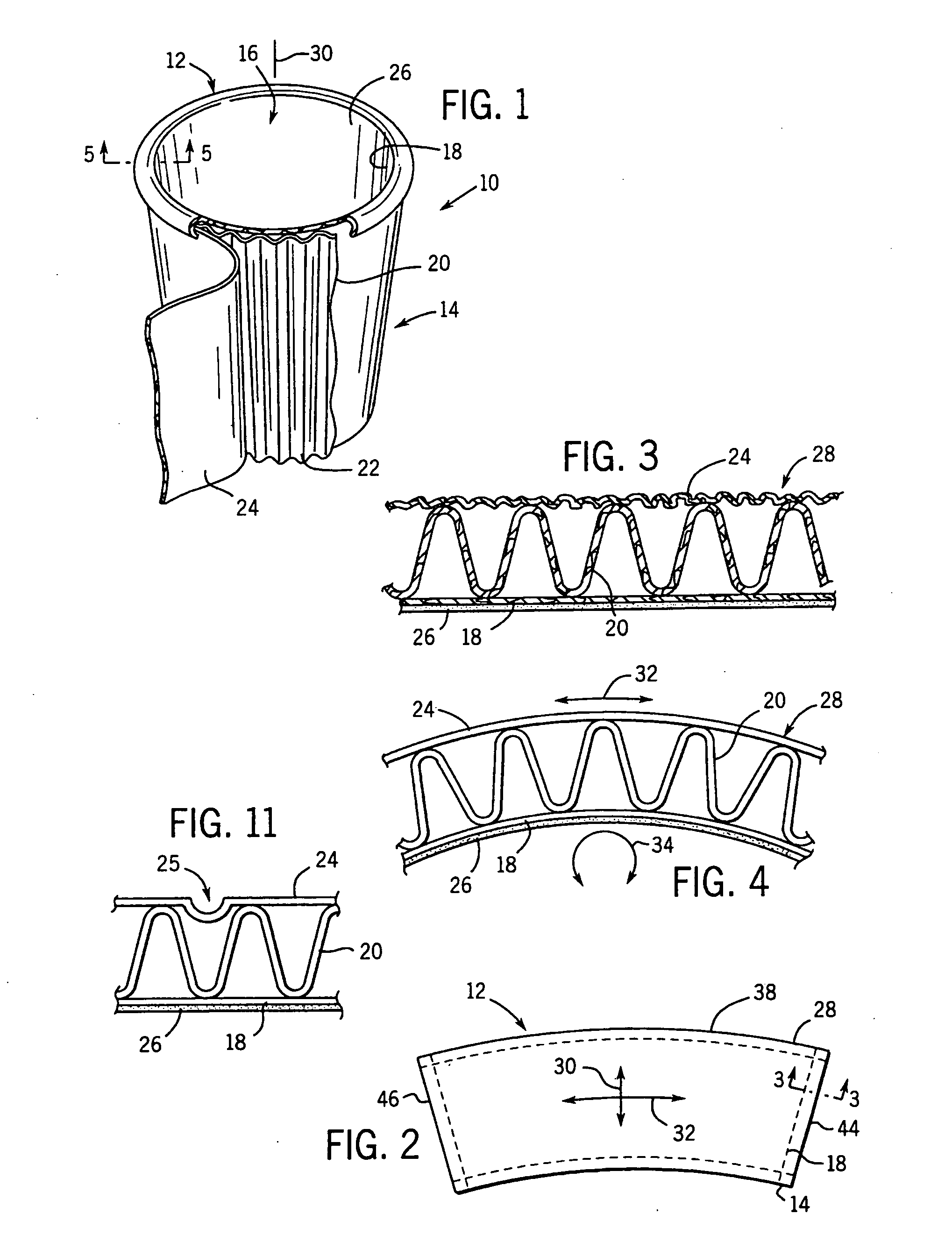

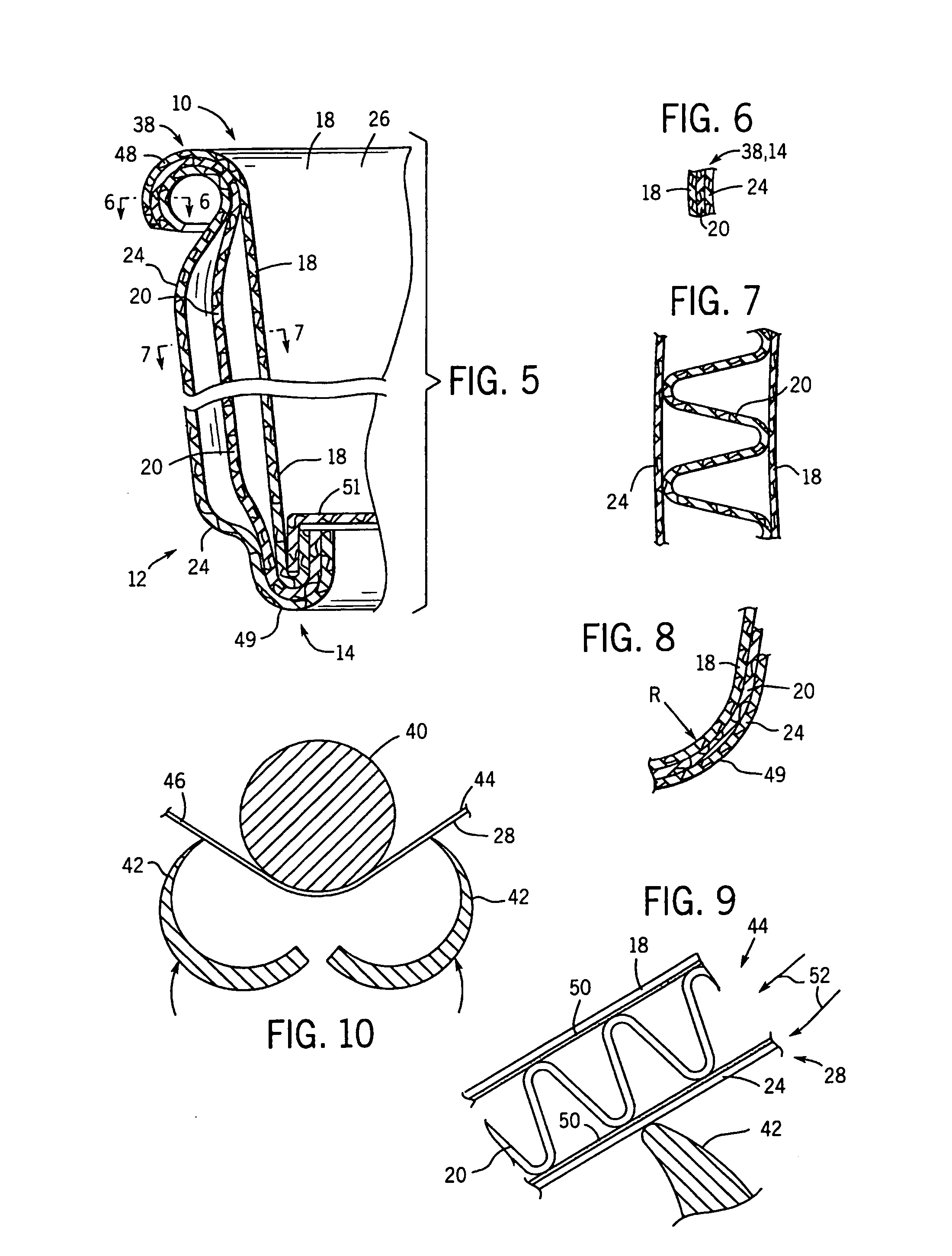

[0043] Referring now to FIG. 1, a cup 10, of the present invention has an upstanding wall 12 rolled into a tube conforming to a frustum of a cone (hereinafter frusto-conical tube) attached at its lower edge 14 to a circular bottom (not shown in FIG. 1) to enclose a beverage receiving volume 16.

[0044] The upstanding wall 12 is composed of a corrugated paperboard material having an inside paper layer 18 immediately adjacent to the beverage containing volume 16 which is surrounded by a middle corrugated paper layer 20 having vertically extending flutes 22. This, corrugated paper layer is in turn, surrounded by an outside paper layer 24 which sandwiches the middle corrugated paper layer 20 between itself and the inside paper layer 18. An adhesive (not shown) connects the middle corrugated paper layer 20 to the inside paper layer 18 and the outside paper layer 24 according to methods well known in the art. The inside paper layer 18 is coated with a thin water resistant coating 26 to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com