Use of hydrophilic-rich alkylmethylsiloxane-dimethylsiloxane-polyoxyalkylene copolymers as emulsifiers for the preparation of cosmetic o/w emulsions of improved aesthetic properties and mildness

a technology of polyoxyalkylene and polymethylsiloxane, which is applied in the field of new hydrophilic-rich organomethylsiloxanedimethylsiloxanepolyoxyalkylene copolymers, can solve the problems of unrecognized use of oh terminal oxyalkylene polyethers, and difficulty in achieving stable disper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 4

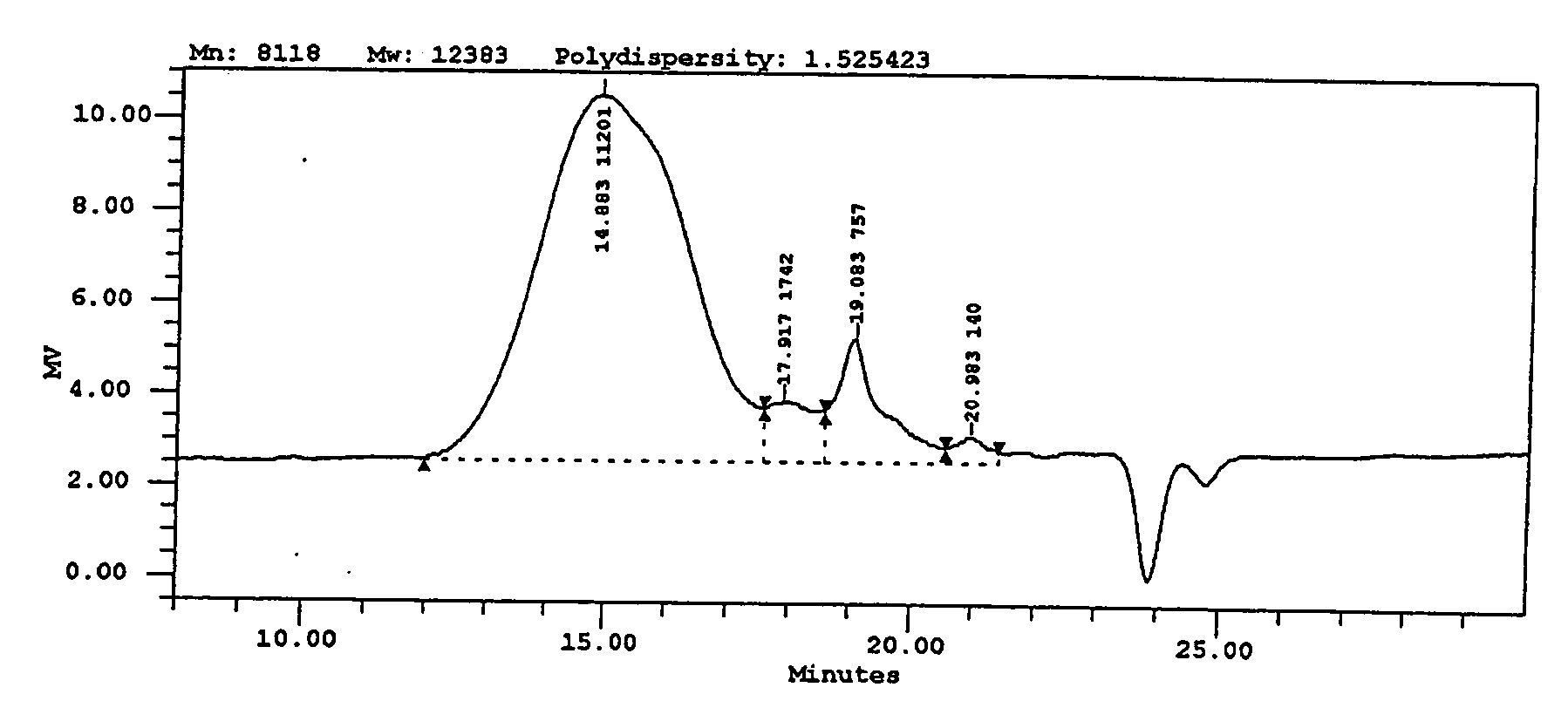

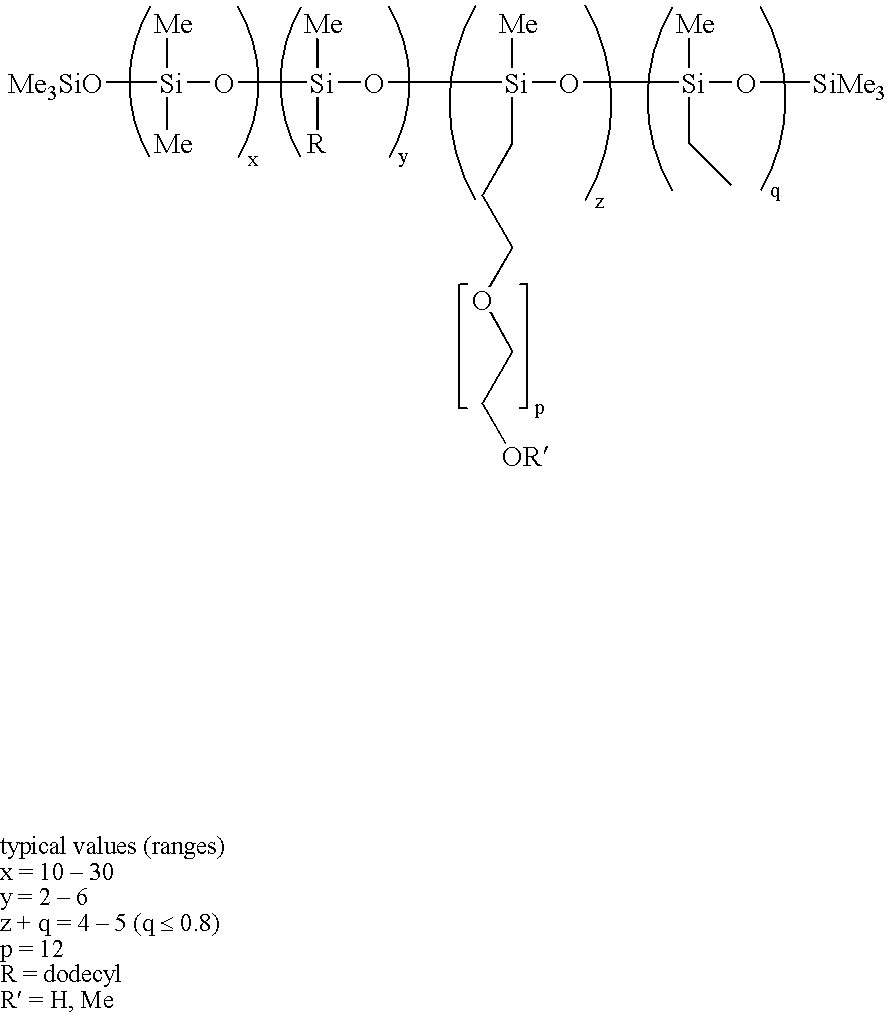

Copolymer where R Dodecyl, R′═H, x=18, y=5, z+q=4, q≦0.8, p=12

[0053]

[0054] Previously nitrogen saturated 1-dodecene (82.58 g, 0.491 mol), silanic hydrogen intermediate Example 1 (200.0 g, 0.0981 mol), and allyl / OH-PEO-12 (92.11 g, 0.157 mol) were combined in a Parr Model 4511 reactor and the head space was purged with nitrogen. The mixture was then stirred and heated to 85° C., whereupon the reactor was opened to allow for the injection of Pt catalyst (192.2 μL of a freshly prepared 0.050 M solution of H2PtCl6.6H2O in isopropyl alcohol). The reactor was sealed and the head space again purged with nitrogen while stirring was initiated, resulting in an exotherm leading to a rapid approximate35° C. increase in temperature. After 43 minutes, the reactor was opened and nitrogen saturated allyl / OH-PEO-12 (138.17 g, 0.235 mol) and additional Pt catalyst (70.7 μL) were added. The reactor was resealed and the stirred reaction allowed continued for an additional 67 minutes. By this time the ...

example 5

Copolymer where R=Dodecyl, R′═H, x=18, y=6, z+q=4, q≦0.8, p=12

[0055]

[0056] Previously nitrogen saturated 1-dodecene (111.08 g, 0.660 mol), silanic hydrogen intermediate Example 2 (230.82 g, 0.110 mol), and allyl / OH-PEO-12 (103.22 g, 0.176 mol) were combined in a Parr Model 4511 reactor and the head space was purged with nitrogen. The mixture was then stirred and heated to 85° C., whereupon the reactor was opened to allow for the injection of Pt catalyst (215.3 μL of a freshly prepared 0.050 M solution of H2PtCl6.6H2O in isopropyl alcohol). The reactor was sealed and the head space again purged with nitrogen while stirring was initiated, resulting in an exotherm leading to a rapid approximate 50° C. increase in temperature. After 30 minutes, the reactor was opened and nitrogen saturated allyl / OH-PEO-12 (154.88 g, 0.264 mol) and additional Pt catalyst (92.3 μL) were added. The reactor was resealed and the stirred reaction allowed continued for an additional 30 minutes. By this time t...

example 6

Copolymer where R Dodecyl, R′=Me, x=18, y=5, z+q 4, q≦0.8, p=12

[0057]

[0058] Previously nitrogen saturated 1-dodecene (82.58 g, 0.491 mol), silanic hydrogen intermediate Example 1 (200.0 g, 0.0981 mol), and allyl / OMe-PEO-12 (94.31 g, 0.157 mol) were combined in a Parr Model 4511 reactor and the head space was purged with nitrogen. The mixture was then stirred and heated to 85° C., whereupon the reactor was opened to allow for the injection of Pt catalyst (186.1 μL of a freshly prepared 0.050 M solution of H2PtCl6.6H2O in isopropyl alcohol). The reactor was sealed and the head space again purged with nitrogen while stirring was initiated, resulting in an exotherm leading to a rapid approximate 42° C. increase in temperature. After 30 minutes, the reactor was opened and nitrogen saturated allyl / OMe-PEO-12 (141.50 g, 0.235 mol) and additional Pt catalyst (79.7 μL) were added. The reactor was resealed and the stirred reaction allowed continued for an additional 60 minutes. By this time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length×19 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com