Ball socket with film backing

a technology of film backing and ball socket, which is applied in the field of ball socket, can solve the problems of frequent creeping of thermoplastics under load, and achieve the effects of simple and inexpensive operation, good strength and creep properties, and good tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

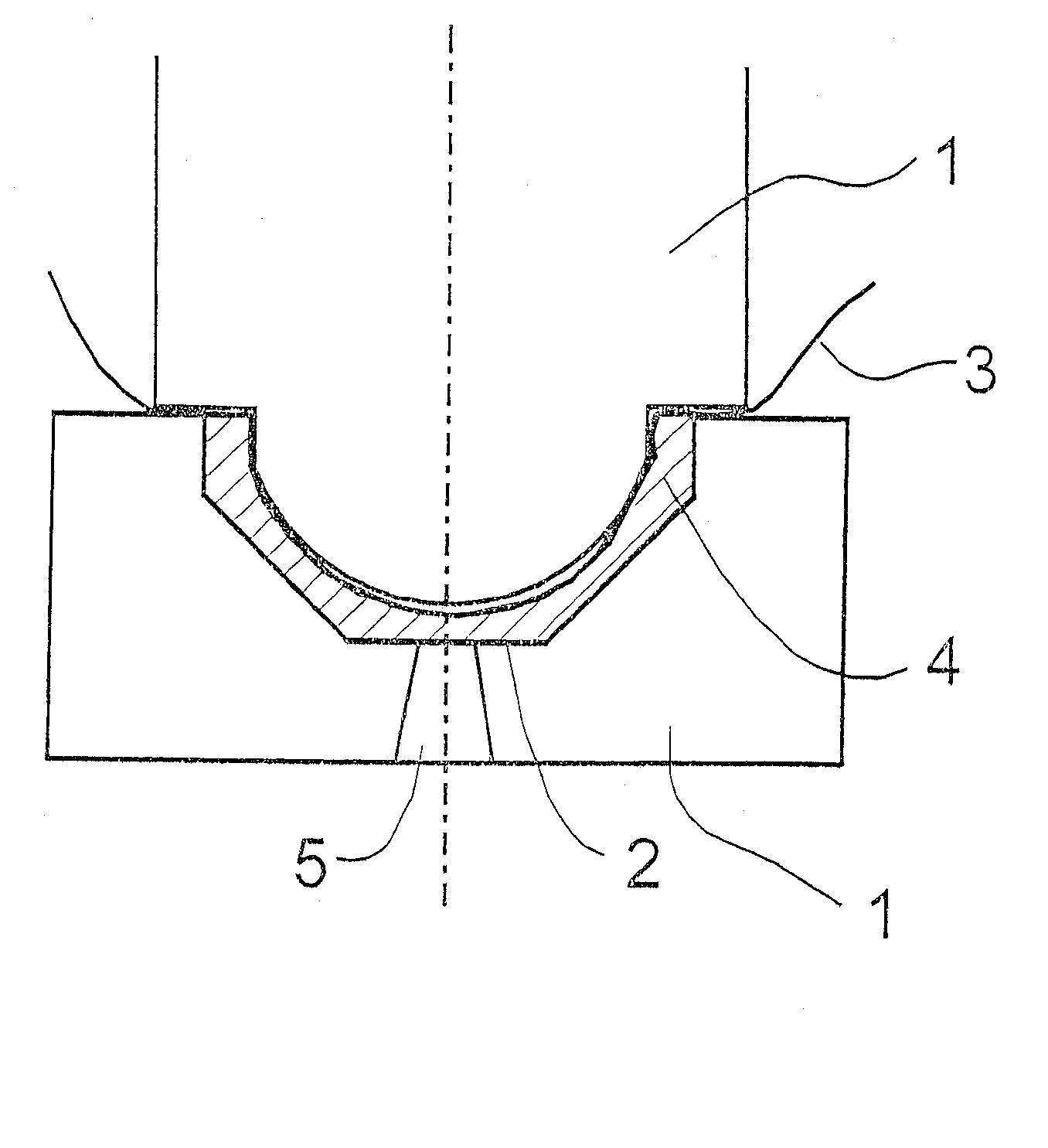

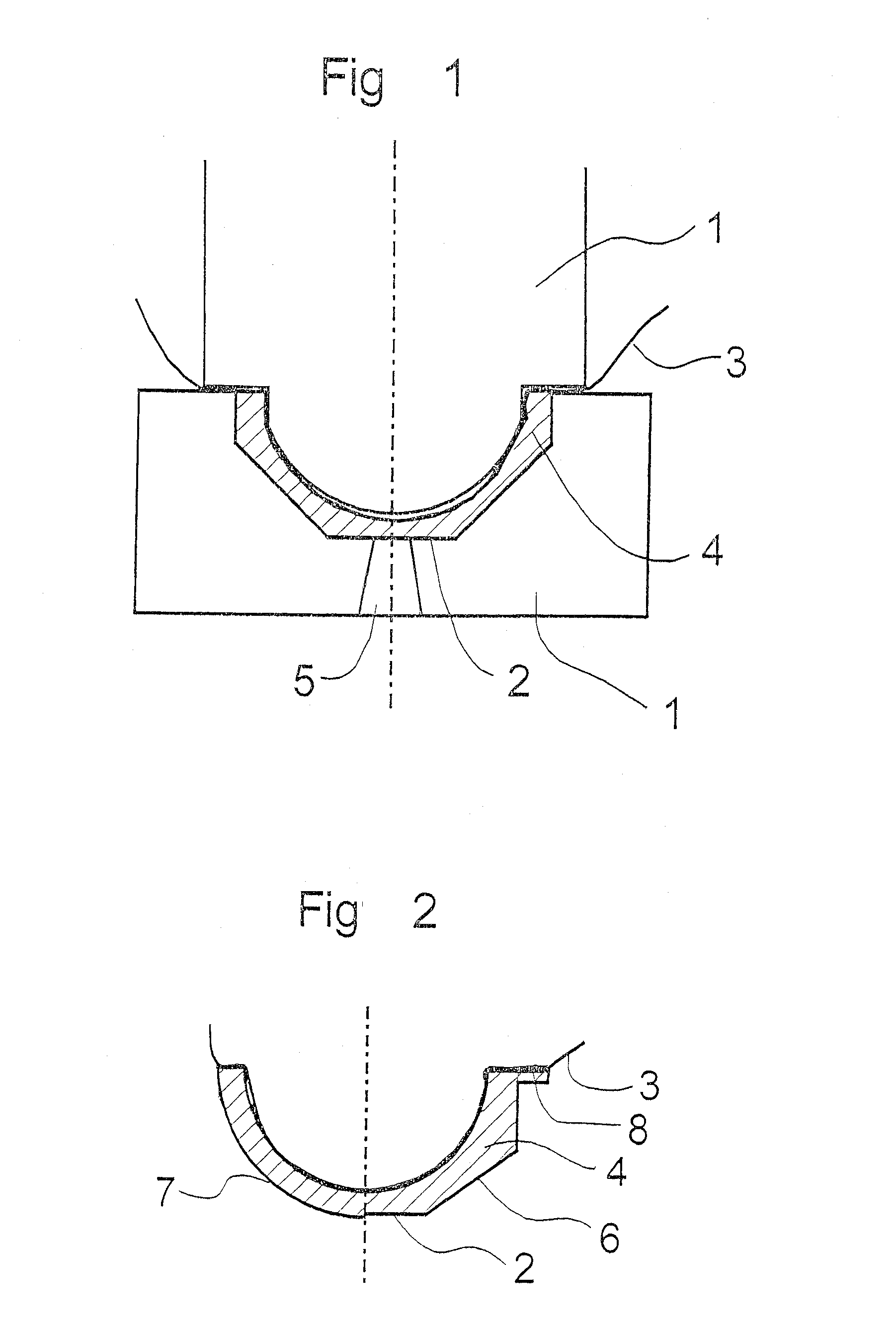

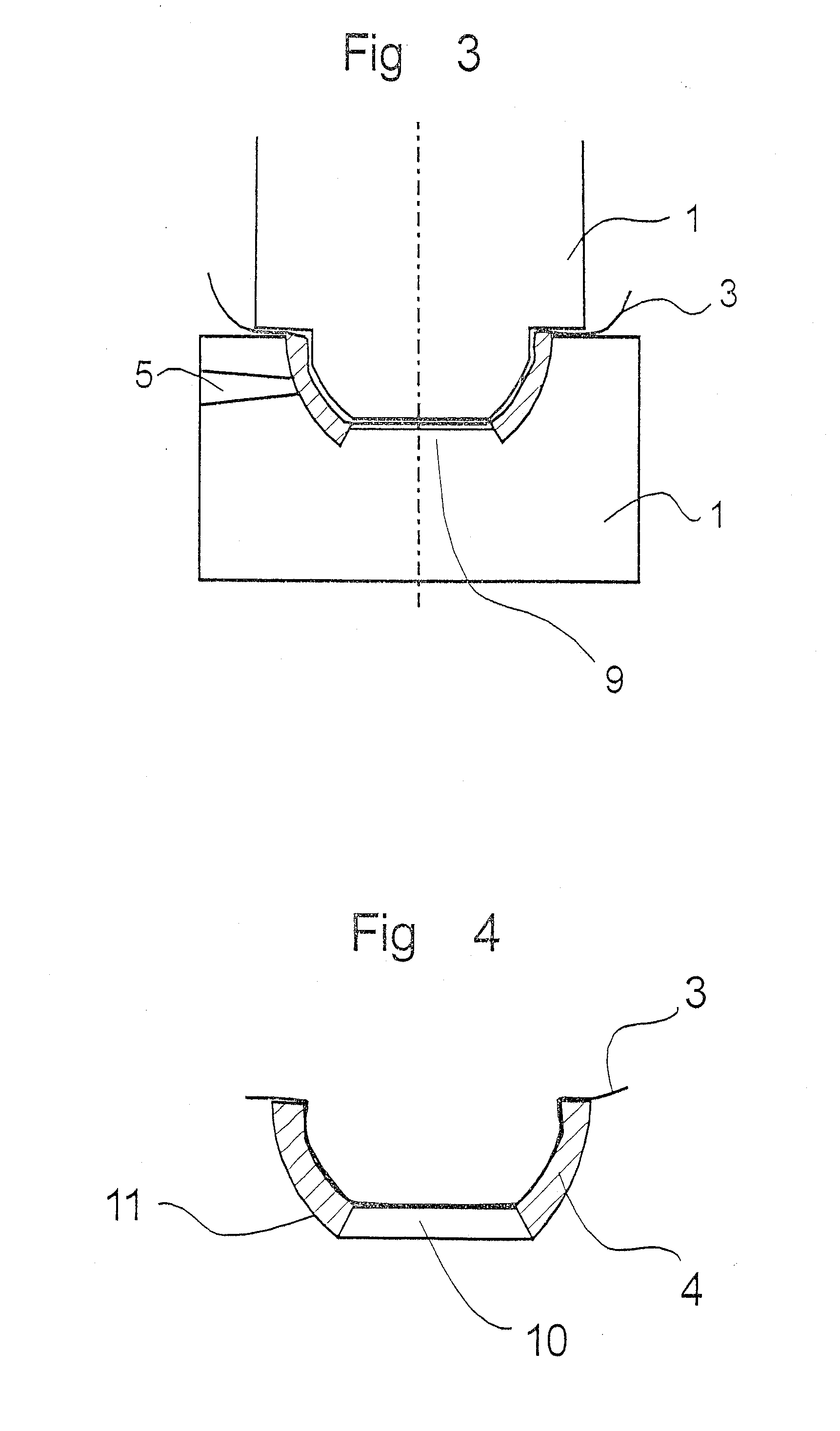

[0017]FIG. 1 shows a cross section through a bearing shell lower part 2 of a multipart bearing shell, which is in the mold 1. The bearing shell lower part 2 has a film 3 with good tribological properties, which is backed with a reinforcing core 4. To prepare the bearing shell lower part 2, a film 3 is first placed into the mold 1. The film 3 may have been preformed in a preceding step, or the forming may be performed by the heated upper part of the mold 1 only when the film 3 is inserted. After the film 3 has been placed into the mold 1, the mold 1 is closed and a plastic 4 used for reinforcement is sprayed behind the film 3. To do so, a corresponding plastic is allowed to enter the closed mold via the sprue 5. Depending on the plastic to be processed, various processes are used. In case of the processing of thermoplastics, the backing of the film is performed predominantly according to a conventional injection molding process. Because of the good adhesive properties of the plastics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com