Viscous Fluid Transferring Device

a fluid transfer device and fluid technology, applied in liquid handling, transportation and packaging, packaging goods types, etc., can solve the problems of increasing the cost of air removal and the capacity decrease, and achieve the effect of increasing the cost of transfer, increasing the operating time of the evacuating mechanism, and increasing the cost of electricity for operating the evacuating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A best mode for carrying out the invention will now be described on the basis of the accompanying drawings. The drawings are to be viewed in the orientation of the reference numbers.

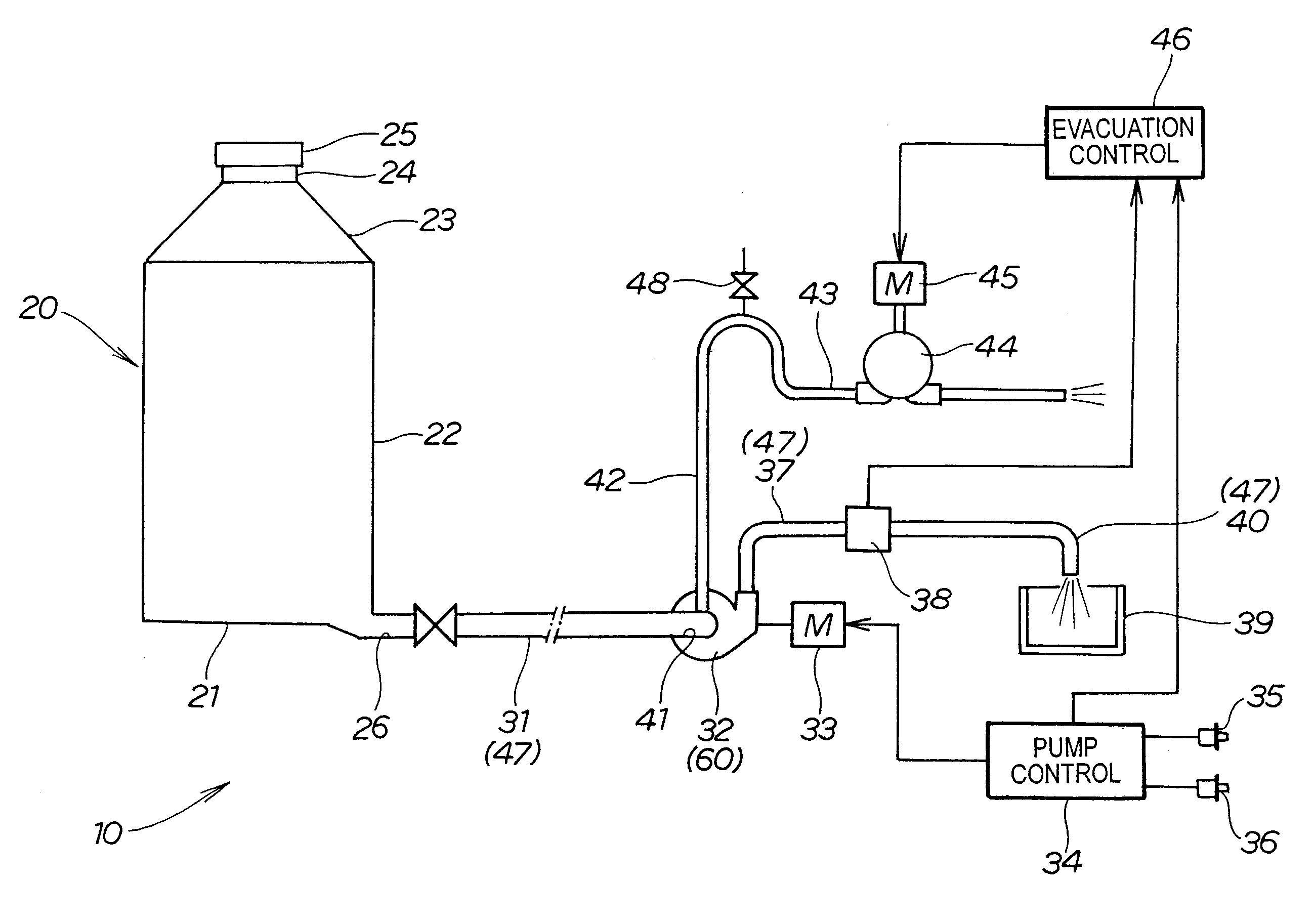

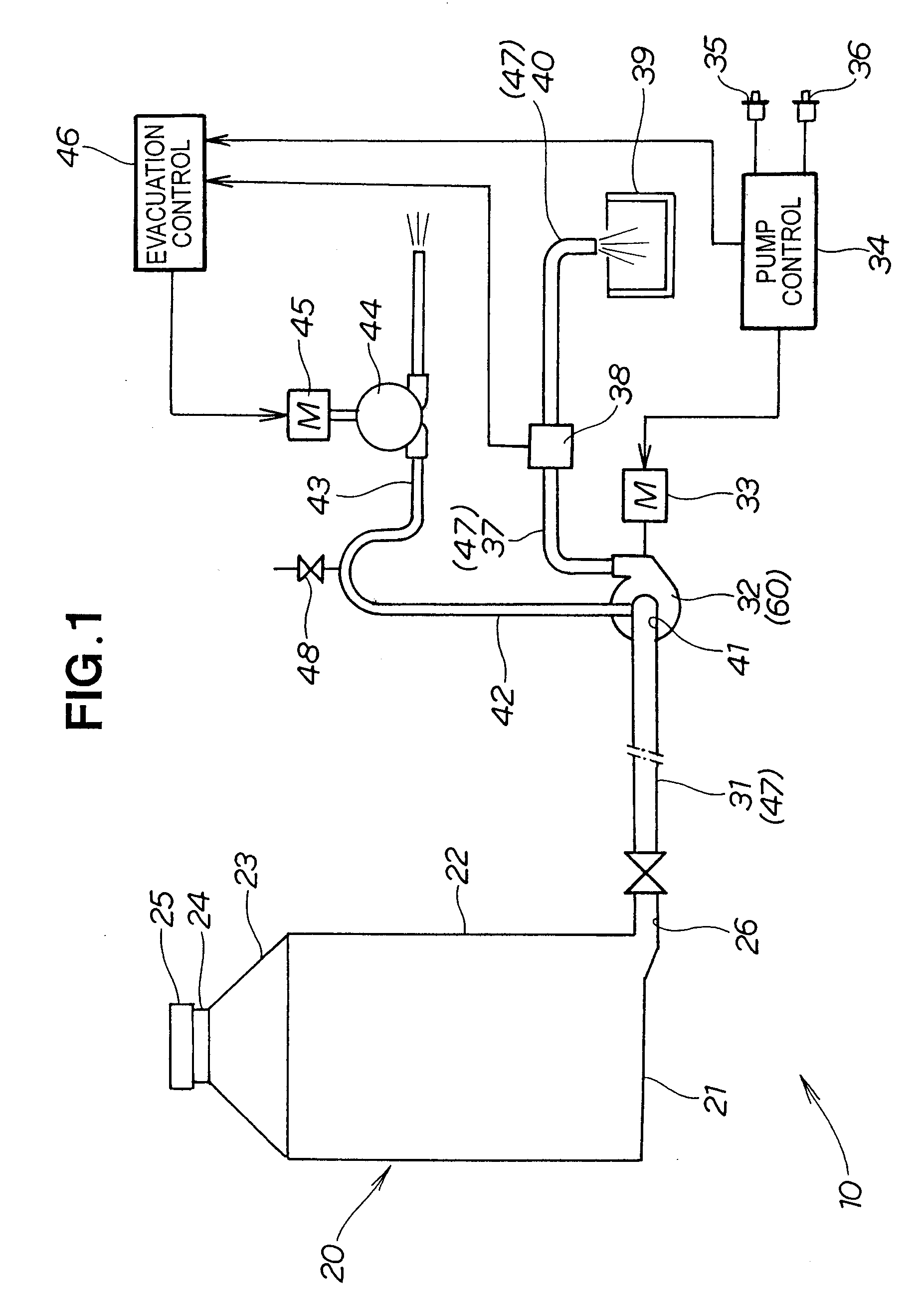

[0033]FIG. 1 is a basic construction view of a transfer apparatus for a viscous fluid, according to the invention.

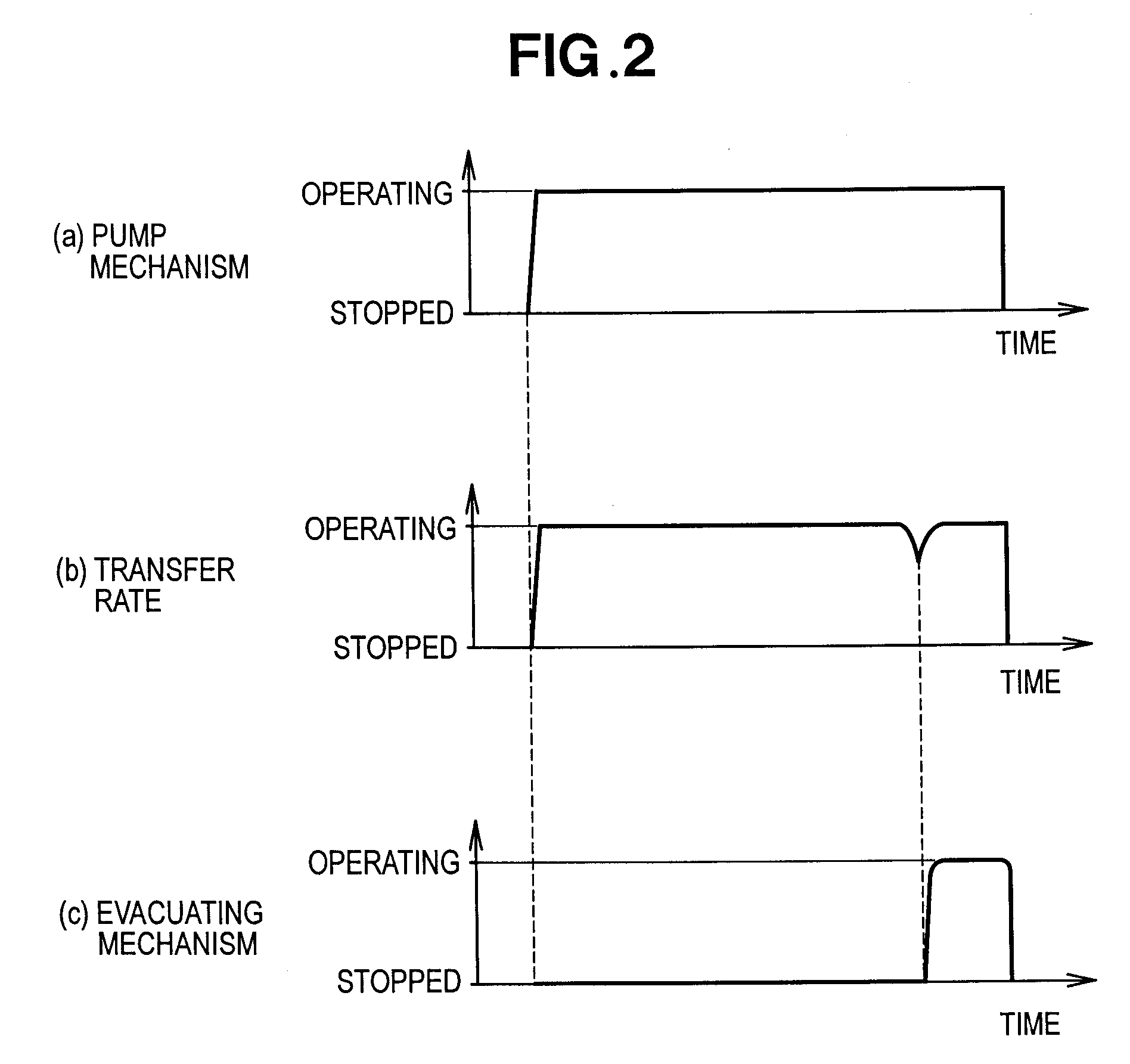

[0034] A transfer apparatus 10 for a mash constituting a viscous fluid is made up of a storage tank 20 for storing mash; a first transfer pipe 31, extending from the bottom of the storage tank 20, for taking mash out; a pump mechanism 32 connected to this first transfer pipe 31; a motor 33 for driving this pump mechanism; a pump control part 34 for controlling the pump mechanism 32 by operating / stopping the motor 33; a pump Start button 35 and a pump Stop button 36 connected to the pump control part 34; a second transfer pipe 37 extending from the pump mechanism 32; a flowmeter 38 connected to this second transfer pipe 37; a third transfer pipe 40 extending from this flowmeter 38 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elevation angle | aaaaa | aaaaa |

| elevation angle | aaaaa | aaaaa |

| viscous | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com