Process and System for Removing Contaminants from a Natural Gas Stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Comparative Example

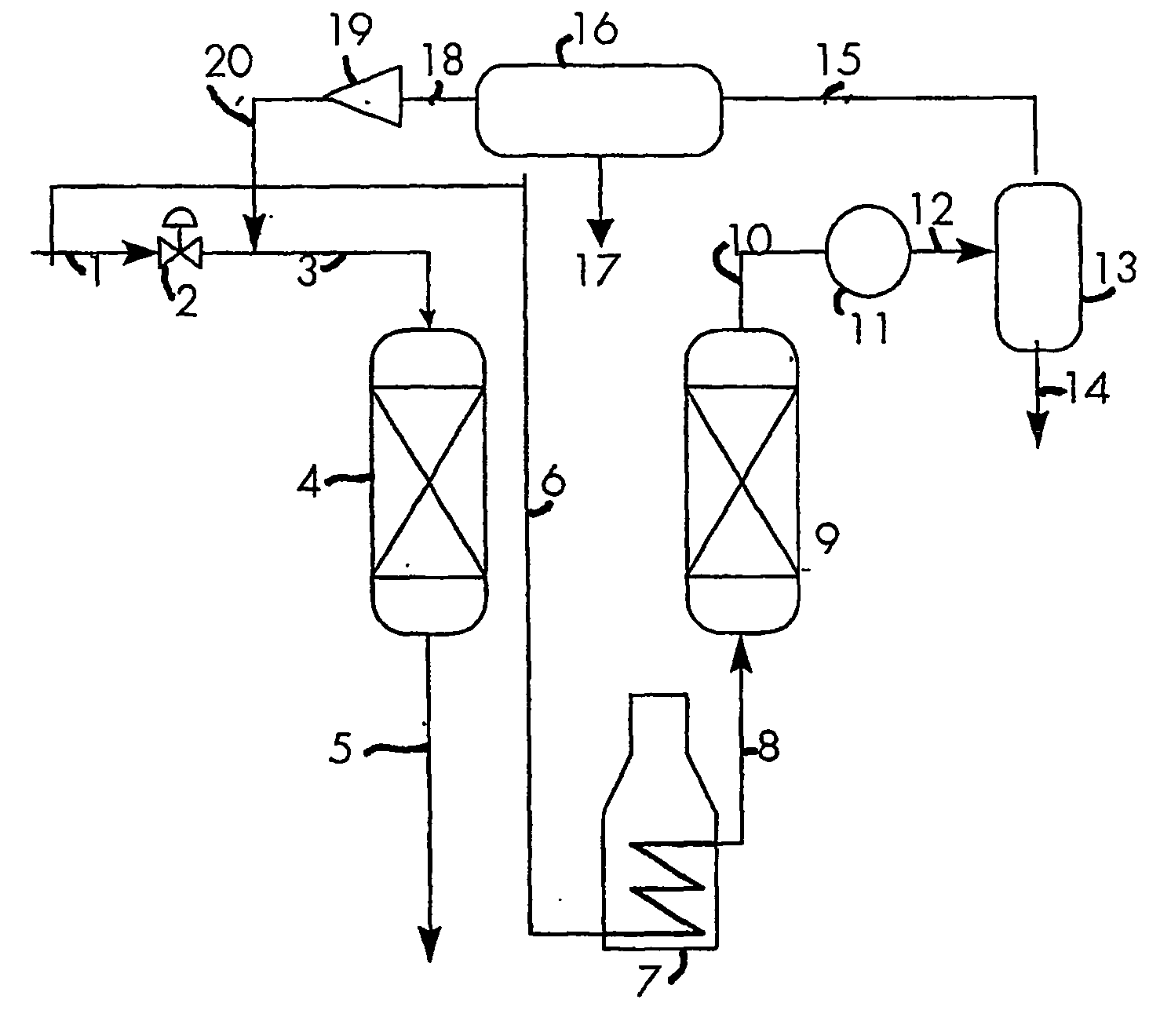

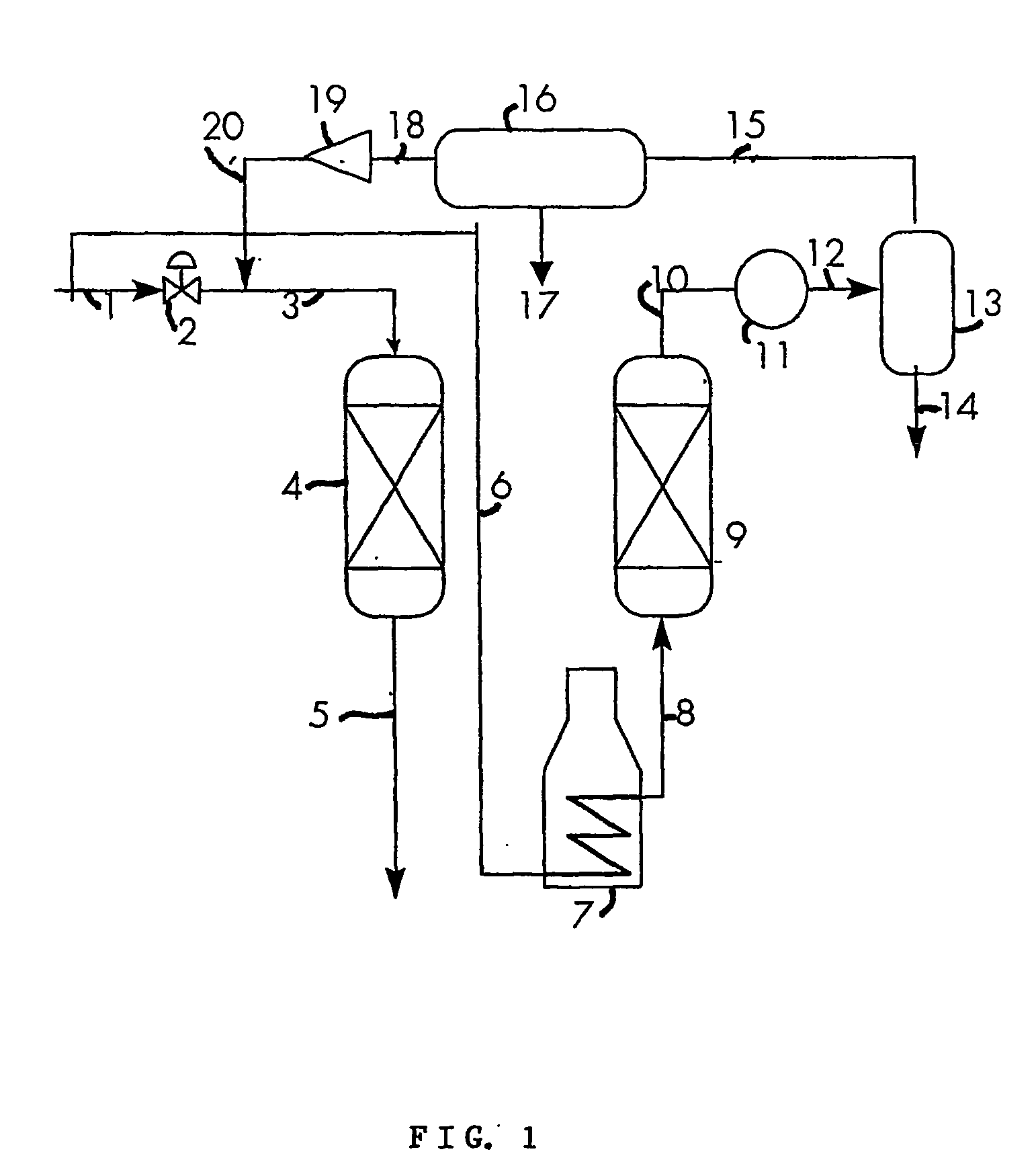

[0087] In the comparative example use is made of a line-up as shown in FIG. 1, but without the separator means 16 and compressor 19. Part of a feed natural gas stream having a composition as shown in Table 1 is contacted with a second adsorbent bed, the second adsorbent bed being in the adsorbing mode. The pressure of the feed gas stream is 80 bara. The temperature of the feed gas is 25° C. Another part (for example 30%) of the feed gas stream is heated to obtain a first heated gas stream. The heated first gas stream is contacted with a first adsorbent bed, the first adsorbent bed being in the regeneration mode, to create a second gas stream enriched in water and C5+ hydrocarbons. The second gas stream is cooled to a temperature such that water and hydrocarbons condense into a first liquid water / hydrocarbon phase. The first liquid water / hydrocarbon phase is separated. The composition of the resulting gas stream is given in Table 1. The resulting gas stream that i...

example 2

[0088] A feed gas having a composition as shown in Table 2 is subjected to a process based on example 1, but now according to the present invention as described in FIG. 1, the cooling device (16) being an accelerated inertia separator. The resulting composition of the 2nd, 3rd and 4th (lean) gas stream are given in Table 2.

TABLE 2Composition of gas streams in example 2 (in mol %).2nd gas3rd gas4th gasFeedstreamstreamstreamC194.713893.564094.388695.0137C21.25361.23071.22821.2220C30.11440.11060.10770.1035N20.49810.49260.49820.5023CO22.81842.77752.79022.7966He0.00010.00010.00010.0001iC40.02090.01970.01850.0167NC40.03080.02850.02620.0224NC50.19920.24770.20030.1255NC60.14940.76590.48110.1609NC70.10000.43960.18140.0244BNZN0.00000.00040.00030.0001NC80.02000.06070.01400.0007TOLU0.00000.00000.00000.0000NC90.01500.03900.00450.0001NC100.00800.01940.00100.0000H2O0.05830.20360.05980.0110100.0000100.0000100.0000100.0000

[0089] It can be seen in this example that overall contaminants have been re...

example 3

[0090] A feed gas having a composition as shown in Table 3 is subjected to a process as described in FIG. 1, the cooling device (16) being a refrigerator, run at 80 bar and −7° C. The resulting composition of the 2nd, 3rd and 4th (lean) gas stream are given in Table 3.

TABLE 3Composition of gas streams in example 3 (in mol %).2nd gas3rd gas4th gasFeedstreamstreamstreamC194.713893.537394.408594.8961C21.25361.23001.22721.2181C30.11440.11070.10760.1038N20.49810.49260.49850.5023CO22.81842.77592.78922.7886He0.00010.00010.00010.0001IC40.02090.01980.01850.0171NC40.03080.02880.02630.0235NC50.19920.23420.18680.1393NC60.14940.76110.46550.2433NC70.10000.48730.19290.0572BNZN0.00000.00050.00030.0001NC80.02000.06230.01360.0019TOLU0.00000.00000.00000.0000NC90.01500.03900.00420.0003NC100.00800.01940.00100.0000H2O0.05830.20100.05980.0082100.0000100.0000100.0000100.0000

[0091] Also in this example that the total methane content is higher as compared to the comparative example, be it somewhat lower th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com