System and method for reducing windage losses in compressor motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

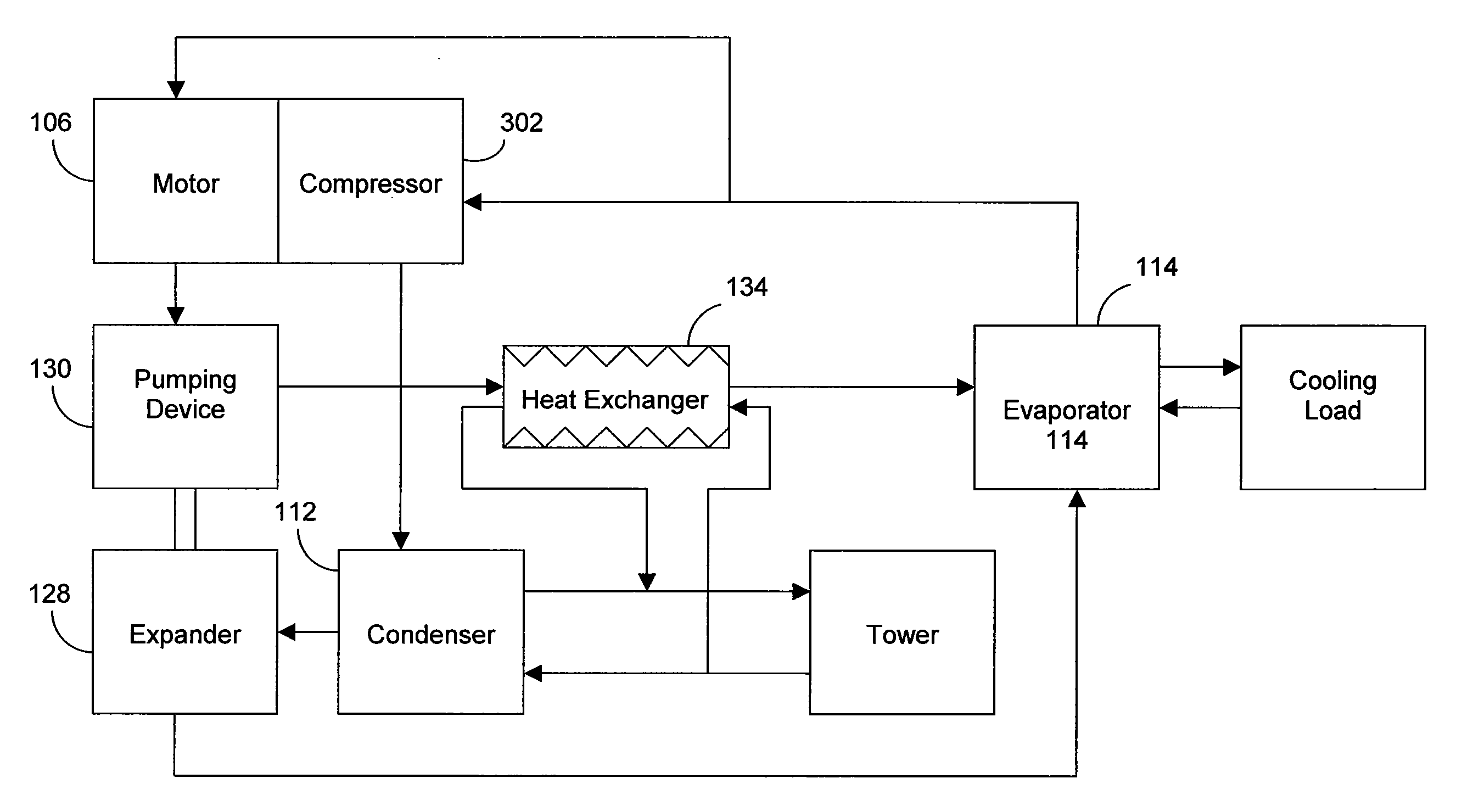

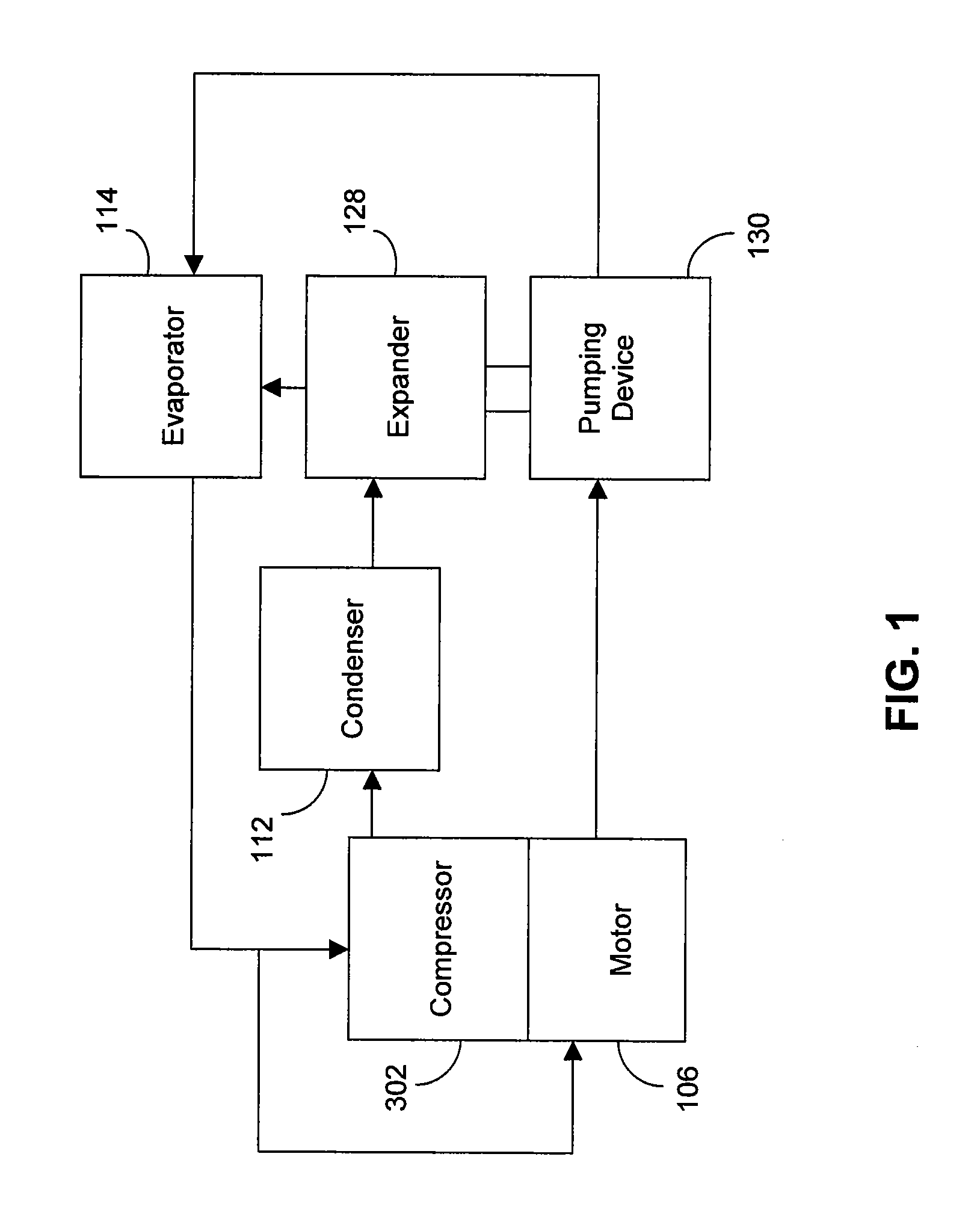

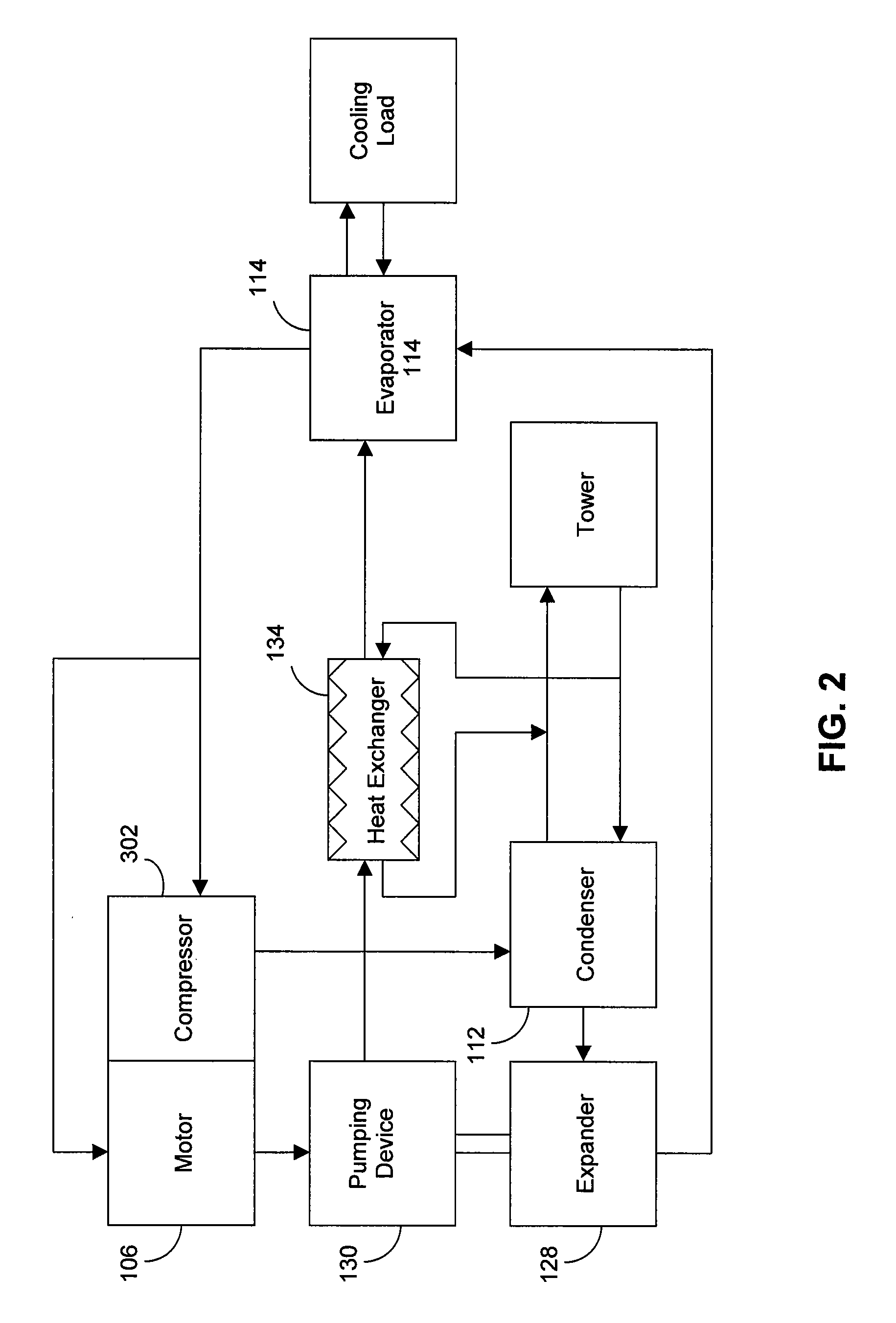

[0020]Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts. Referring to FIG. 1, the HVAC, refrigeration or liquid chiller system includes a compressor 302, a condenser arrangement 112, and a liquid chilling evaporator arrangement 114 connected in a refrigerant loop. In a preferred embodiment, the chiller system has a capacity of 250 tons or greater and even more preferably, has a capacity of 1000 tons or greater. A motor 106 is connected to the compressor 302 to power the compressor 302. The motor 106 and compressor 302 are preferably housed in a common hermetic enclosure, but can be housed in separate hermetic enclosures. The compressor 302 compresses a refrigerant vapor and delivers high pressure vapor to the condenser 112 through a discharge line. The compressor 302 is preferably a centrifugal compressor; however, the compressor 302 can be any suitable type of compressor including a screw compressor, a reciprocatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com