Hydraulic downhole oil recovery system

a hydraulic and oil recovery technology, applied in the direction of fluid removal, gearing, borehole/well accessories, etc., can solve the problems of inability to achieve, limited oil recovery depth and volume, and hampered conventional oil recovery systems, so as to reduce the efficiency of hydraulic fluid, avoid power loss, and improve the effect of operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

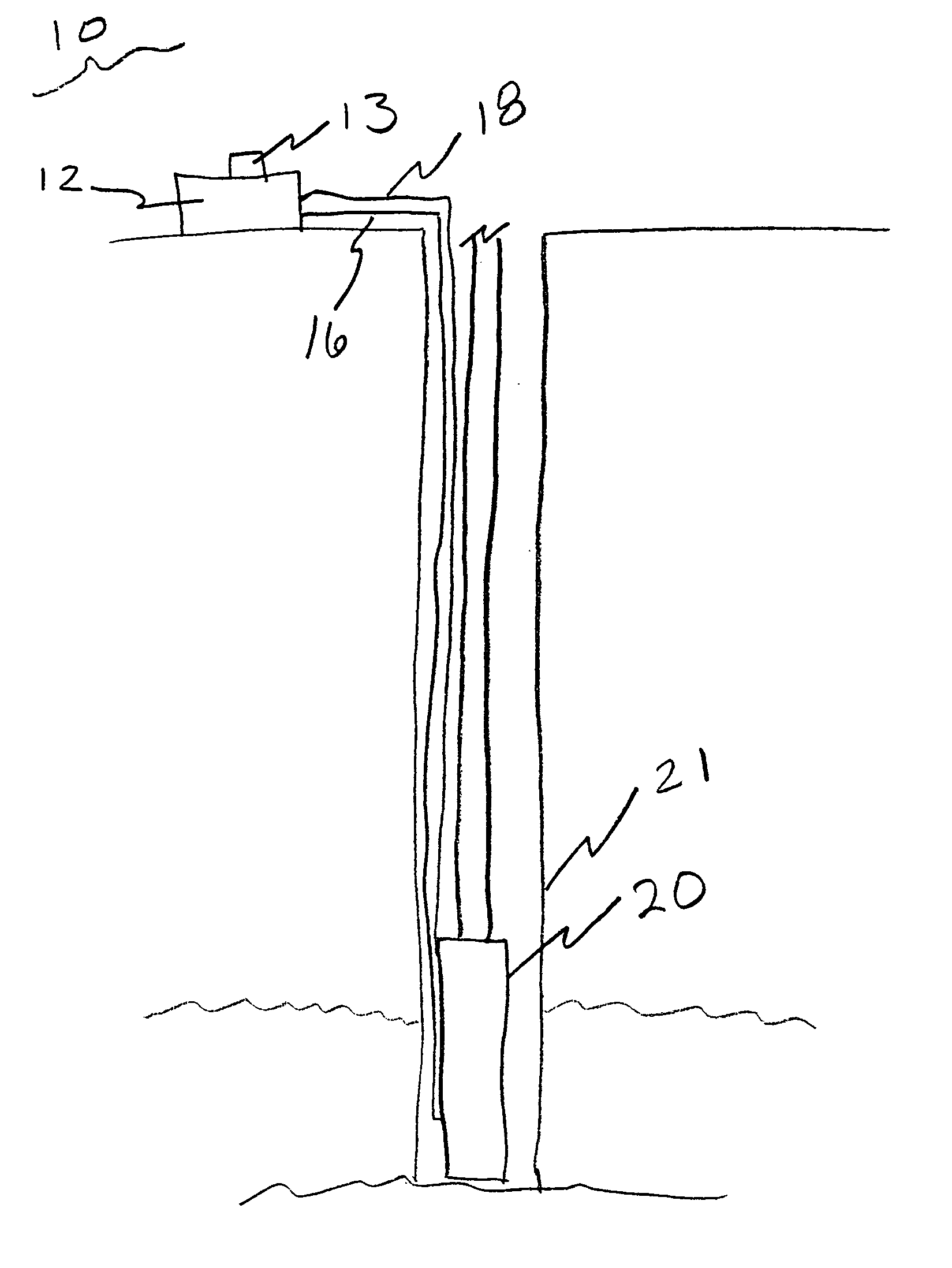

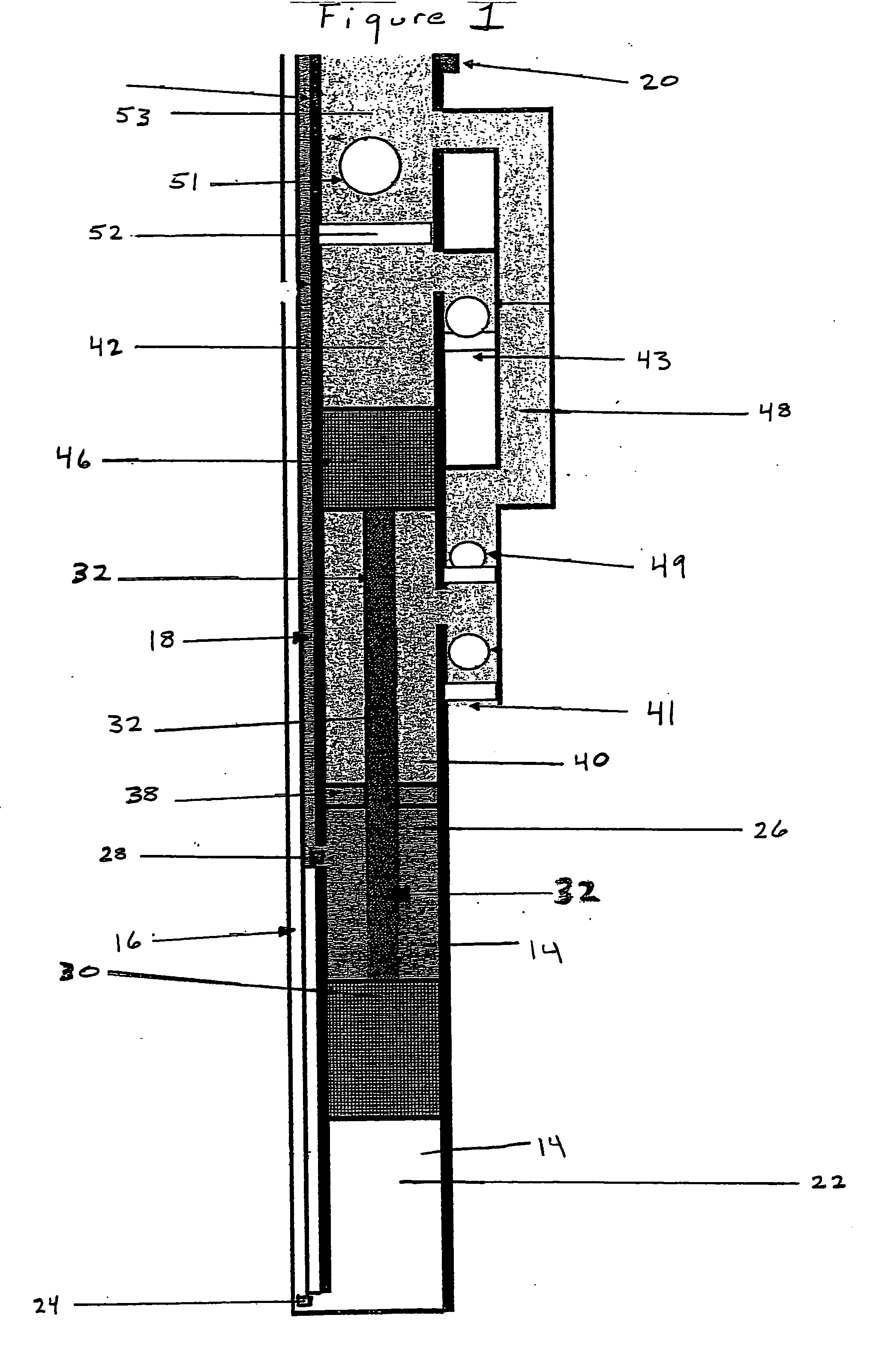

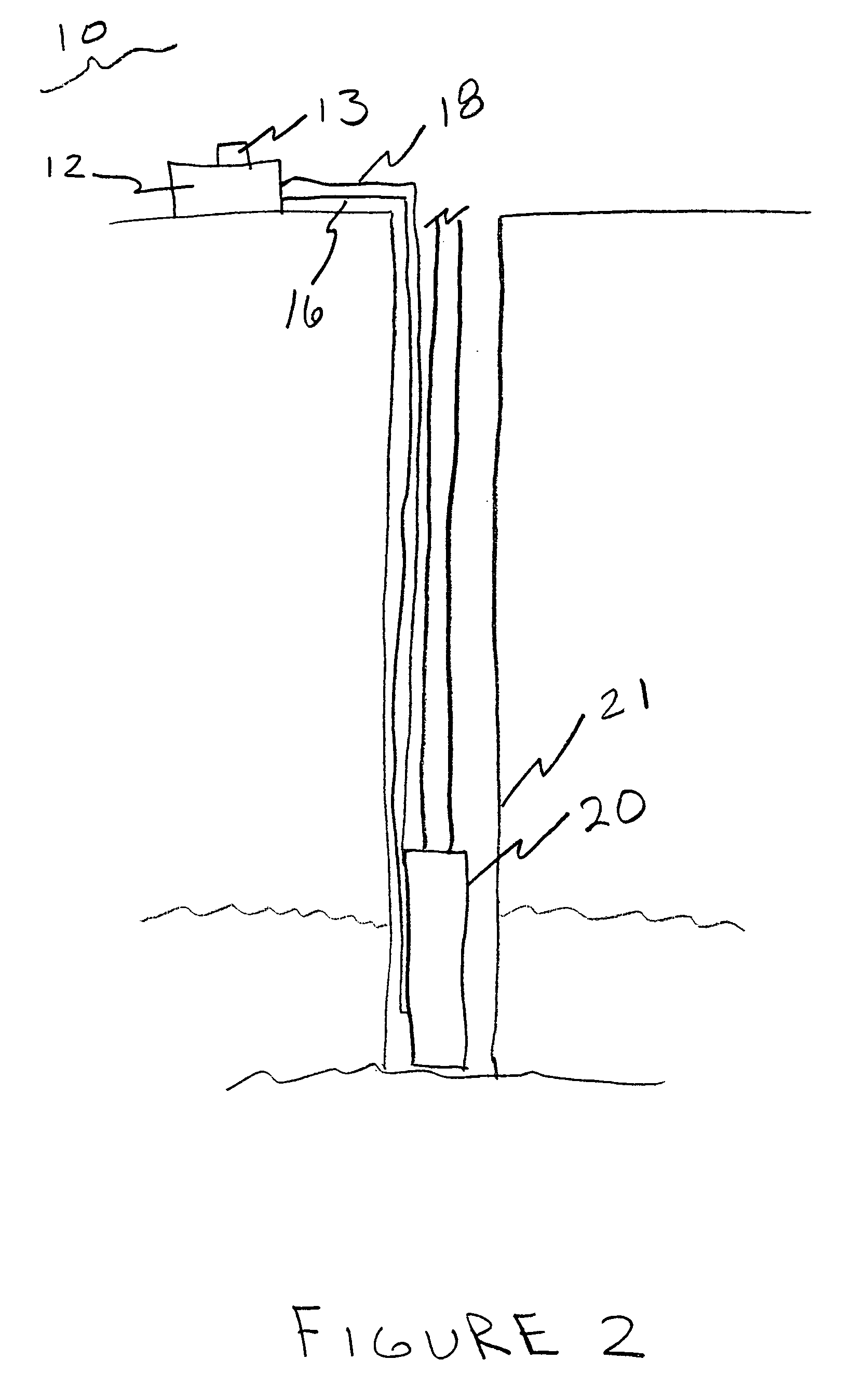

[0055] With reference to FIG. 2, the improved hydraulic down-hole oil recovery system of the present invention is identified generally by the reference number 10. In the preferred embodiment, device 10 includes surface pump unit 12. Surface pump unit 12 sends a power fluid 14 through upstroke power line 16 during one cycle and sends power fluid 14 through down-stroke power line 18 in a following down-stroke cycle. Surface unit 12 reversibly engages with power lines 16 and 18 so as to form a fluid-tight seal, such seal is formed by standard tube fittings as known in the art. In the preferred embodiment, pump unit 12 is a pressure pump, modified to contain a“switch off pressure sensor”13 which reads the pressure at the surface pump on both the upstroke and the down-stroke. At the point each stroke is carried out, pressure increases beyond a preset “switch off” point where sensor 13 sends a signal to pump 12 to begin the next stroke. Further, surface unit 12 transfers power fluid 14 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com