Multi-joint fixture system

a fixture system and joint technology, applied in the field of multi-joint fixture system, can solve the problems of increasing the risk of the instrument being held with less strength and/or precision than is desirable, the fixture is manual intensive and cumbersome, and the practitioner is fatigued, etc., to achieve the effect of increasing the level of force, reducing the risk of the instrument being held with less strength and/or precision, and high degree of positional flexibility and ease of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

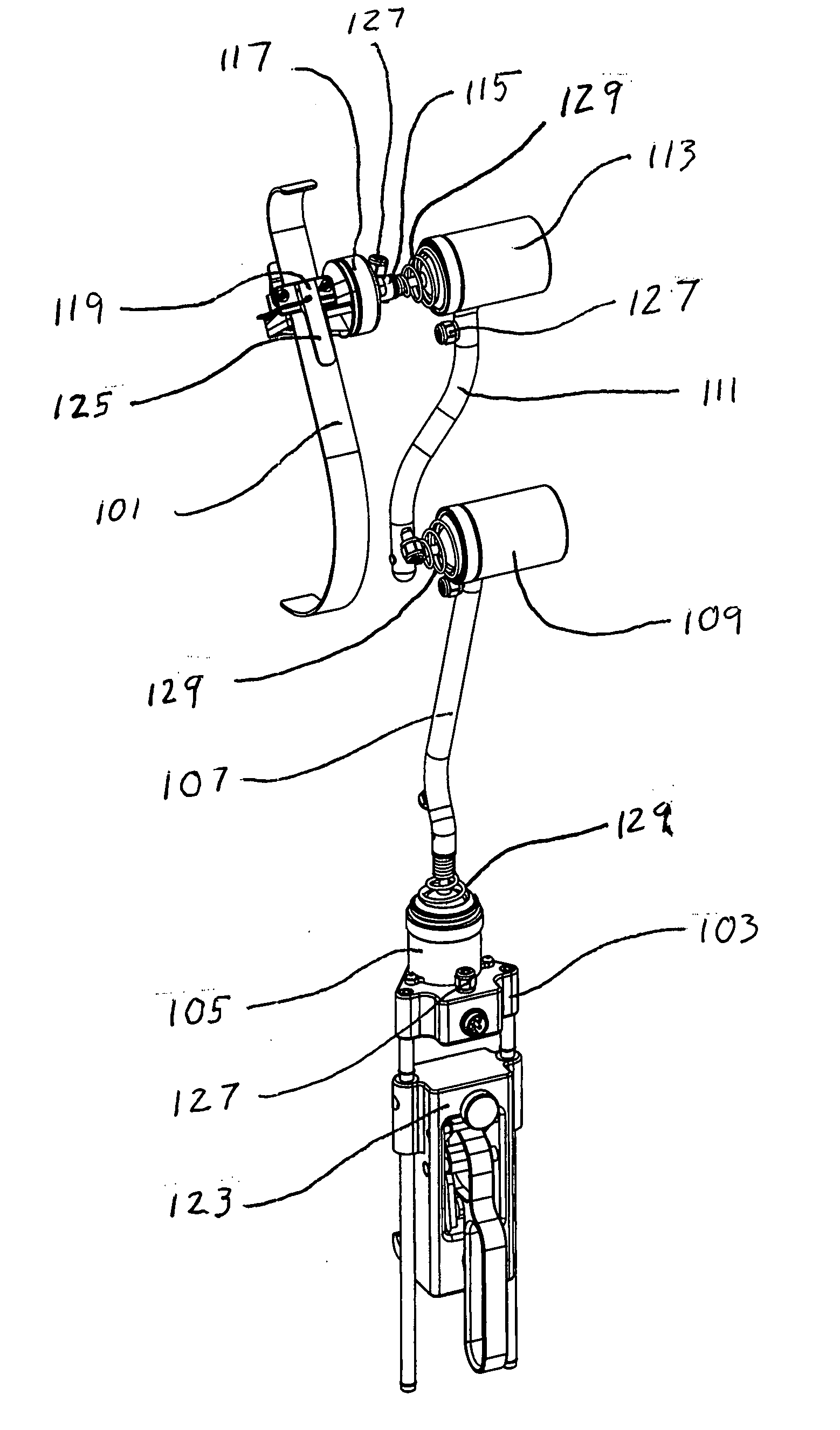

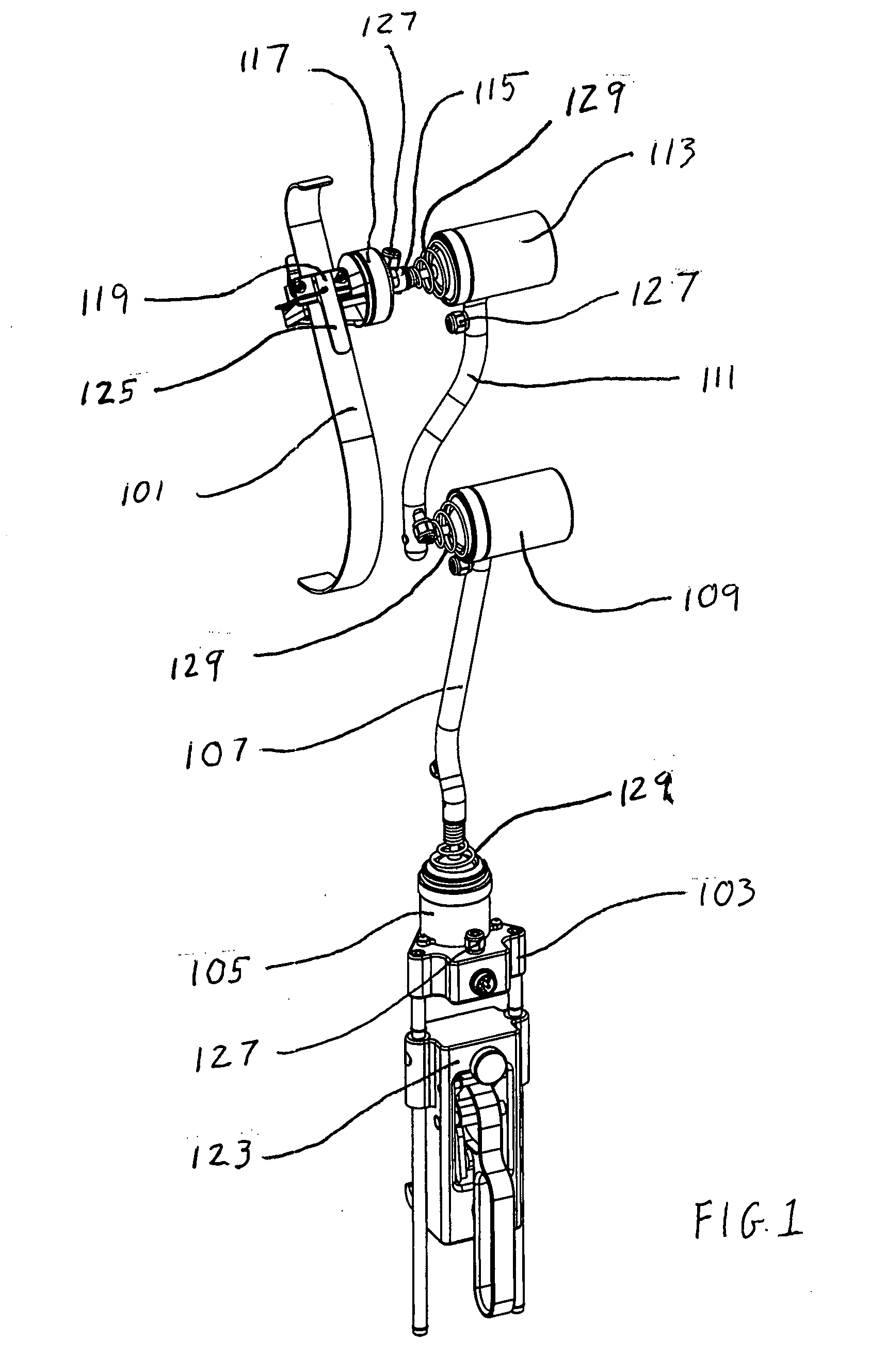

[0031]With reference to FIG. 1, the invention forms a multi-joint fixture for holding a surgical instrument 101 such as a surgical retractor (shown), an endoscope, a limb positioner, or the like. In this context, the term instrument should be understood to include any useful object that a medical practitioner might wish to be held stationary during surgery.

[0032]The fixture includes a base unit 103, a first joint 105, a first arm 107, a second joint 109, a second arm 111, a third joint 113 and a fixture hub 115. The first joint adjustably connects a proximal end of the first arm to the base unit, the second joint adjustably connects a proximal end of the second arm to a distal end of the first arm, and the third joint adjustably connects the fixture hub to a distal end of the second arm. The fixture thus includes a plurality of three joints interconnecting a plurality of four members (including the two arms), each joint having an attached member to which it is rigidly attached and a...

second embodiment

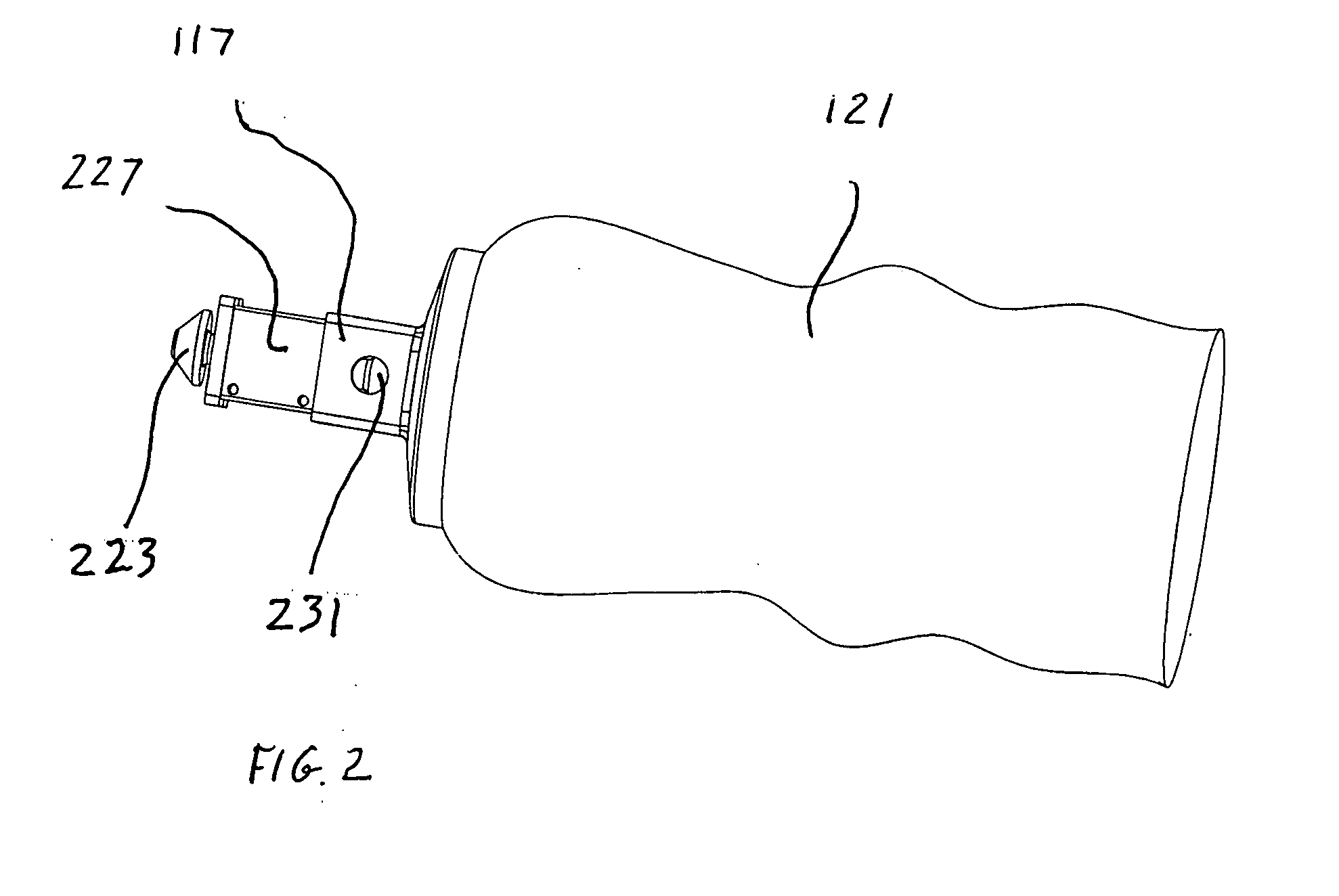

[0094]The offset ball joint of this second embodiment is of an offset configuration in that its actuation elements (e.g., an electromagnet, and a draw-plate that establishes a closable gap with the electromagnet) and its braking elements (e.g., a plurality of hardened ring brake elements on opposing sides of the ball) extend and act along two separate, offset and parallel longitudinal axes. It is also of a levered configuration, in that the lever arm provides a four to one mechanical advantage, allowing for a smaller electromagnet to be used.

[0095]If the primary housing is rigidly attached to (or unitary with) an arm, the offset configuration of this joint provides a simple way for the masses of the housing, the electromagnetic brake mechanism (e.g., the electromagnet and draw-plate), and the spherical portion of the ball to all be placed substantially along a longitudinal arm axis (i.e., an axis generally defined by the extent of the arm from its proximal to its distal end), while ...

third embodiment

[0103]This third embodiment is an example of a fixture characterized by a failsafe locked configuration, and uses joints that lack a levered configuration to leverage the applied braking force to a higher value than that actually generated by their magnets. Other failsafe, locked joint configurations, such as offset configurations and / or levered configurations are also envisioned.

[0104]While the first and third and embodiments were described as fixtures having a single type of ball joint, the second embodiment was described as having a first ball joint in a linear, levered, failsafe unlocked configuration, and a second and third ball joint in an offset, levered, failsafe unlocked configuration. Embodiments having other combinations of ball joints are also envisioned. For example, it is envisioned that a multi-joint fixture could have a first ball joint characterized by a failsafe locked configuration, and second and third ball joints characterized by a failsafe unlocked configuratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com