Programmable energy saving register vent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

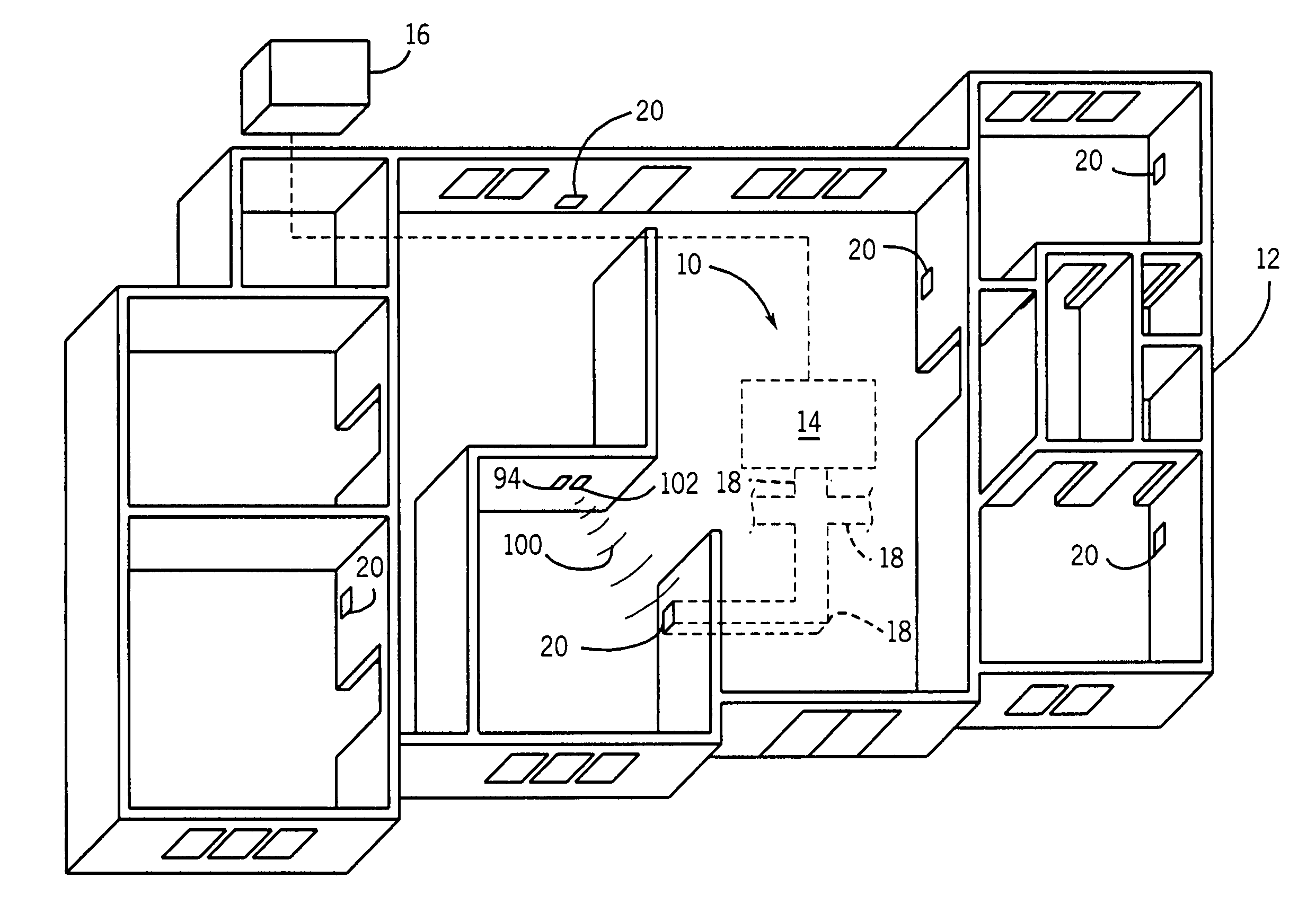

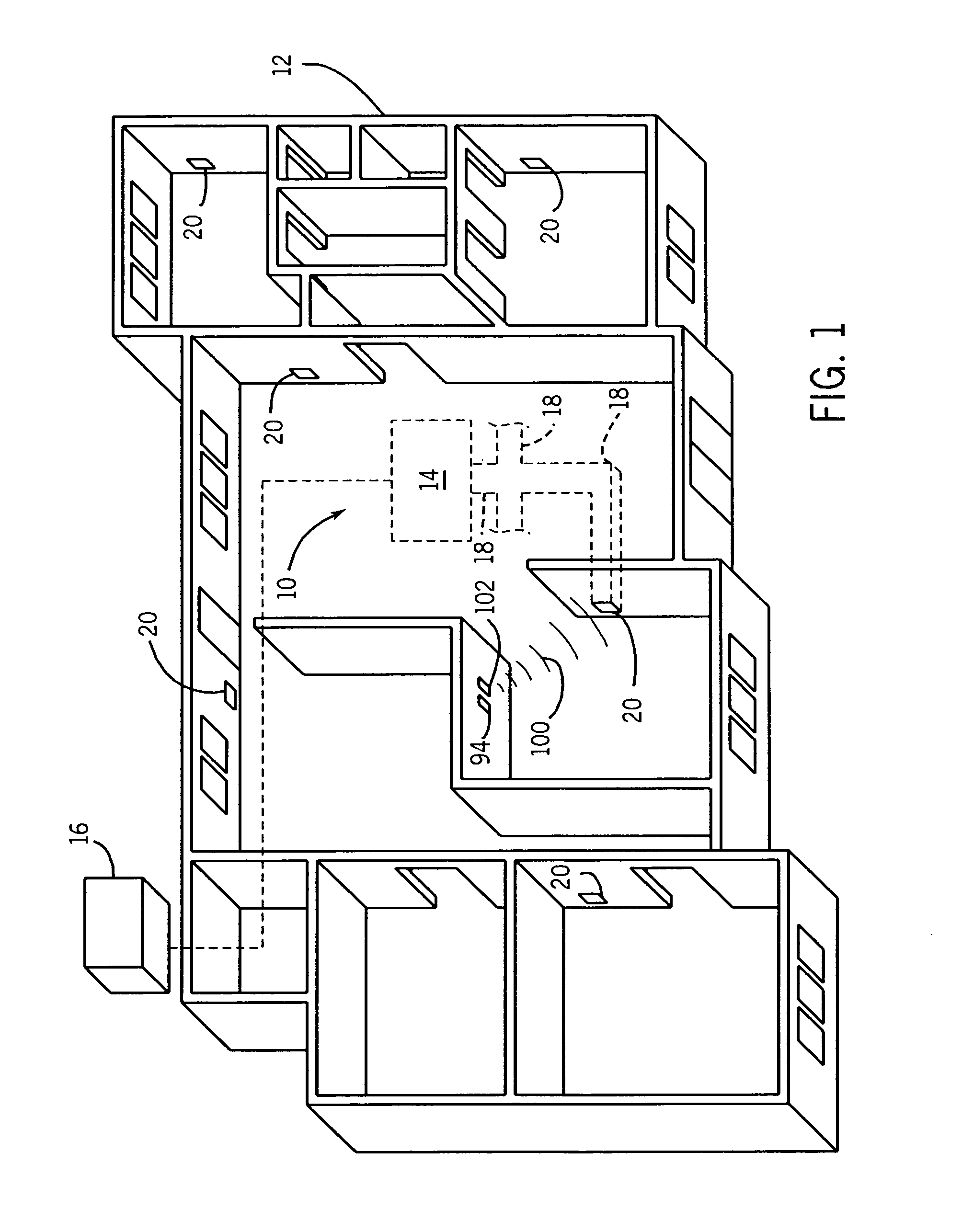

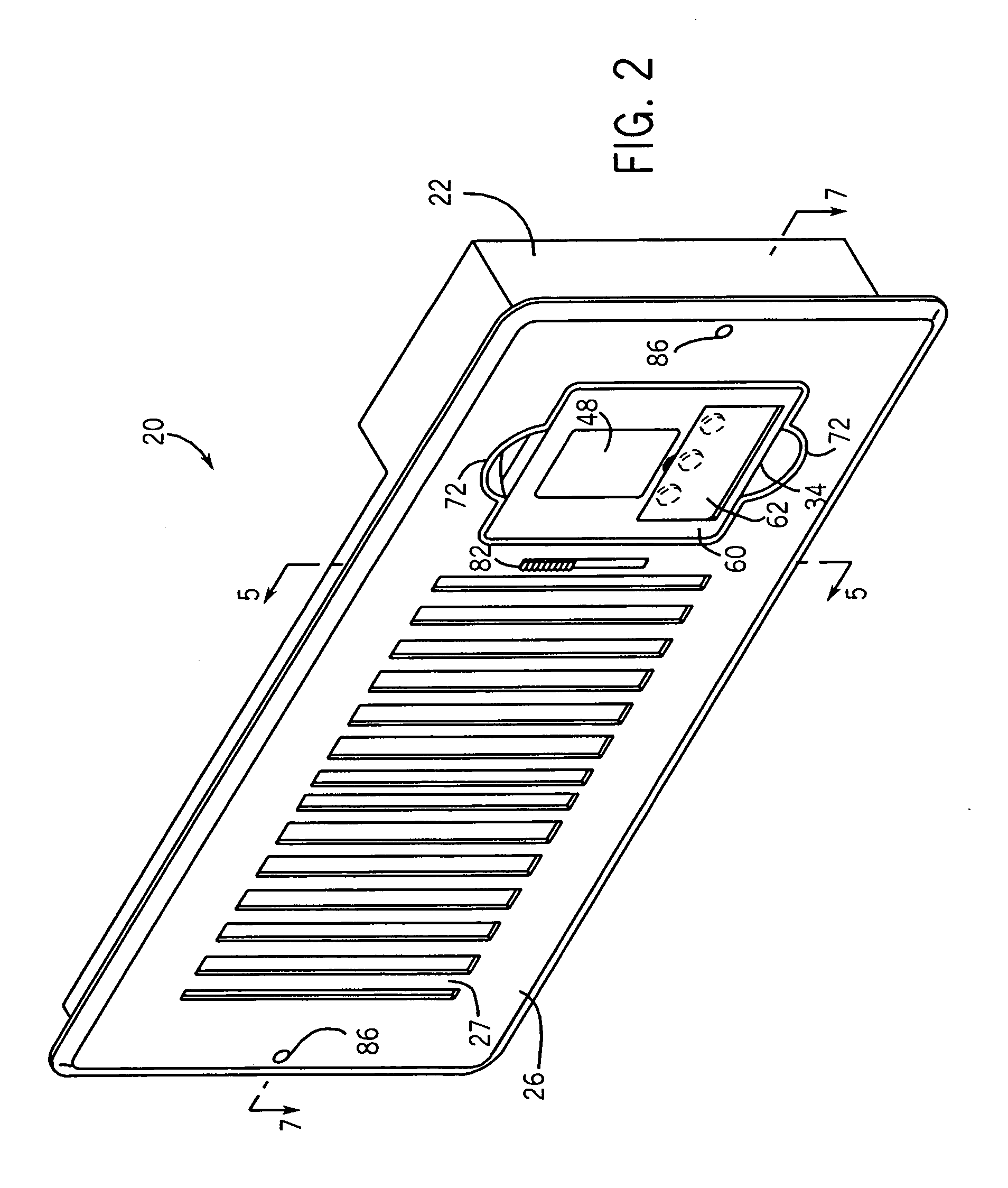

[0063]With initial reference to FIG. 1, there is shown a building environmental air temperature control system 10, such as an HVAC system, located in building 12. System 10 can include at least one of a heating system and a cooling system, such as furnace 14 connected to air conditioning compressor 16. Furnace 14 can typically be a forced air system including a burner / heat exchanger unit and a blower (all not shown), or alternatively a gravity system, or other system. Further, furnace 14 can include other elements such as controls and thermostats (also not shown). At least one duct 18 is connected to furnace 14. Programmable vents 20 are connected to corresponding ducts 18. System 10, and more particularly programmable vents 20, can be used during a daytime setting in a cooling, or summer, season; during a nighttime setting in a heating, or winter, season; or other configurations, for example: a daytime setting in a heating, or winter, season; or a nighttime setting in a cooling, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com