Power tool with spindle lock

a technology of power tools and spindles, which is applied in the direction of portable power-driven tools, metal-working equipment, portable grinding machines, etc., can solve the problems of large force required to ultimately “set” the screw, the hand grinder cannot reach many hidden or obstructed work surfaces, and requires excessive work or modification to reach many work surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

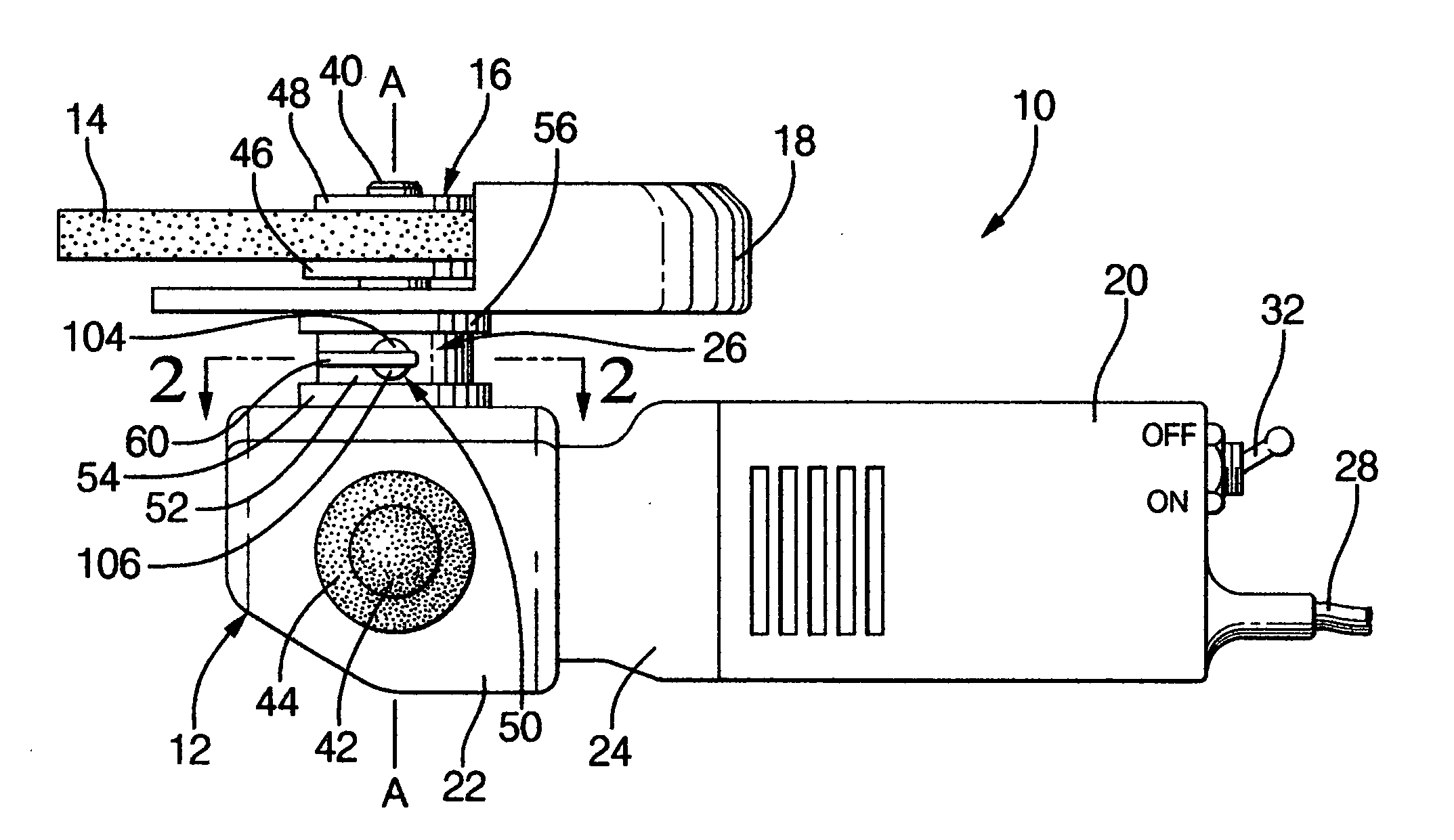

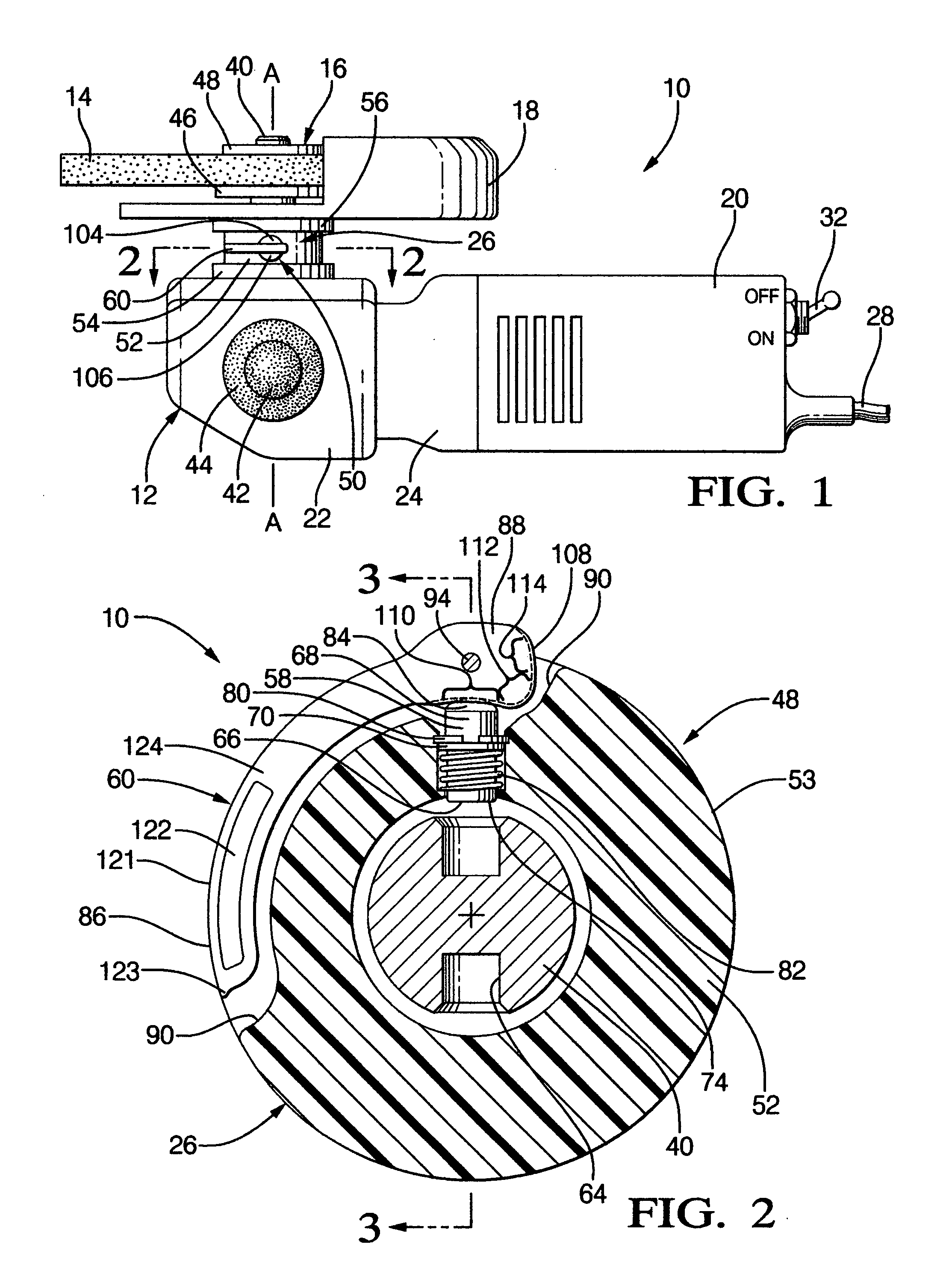

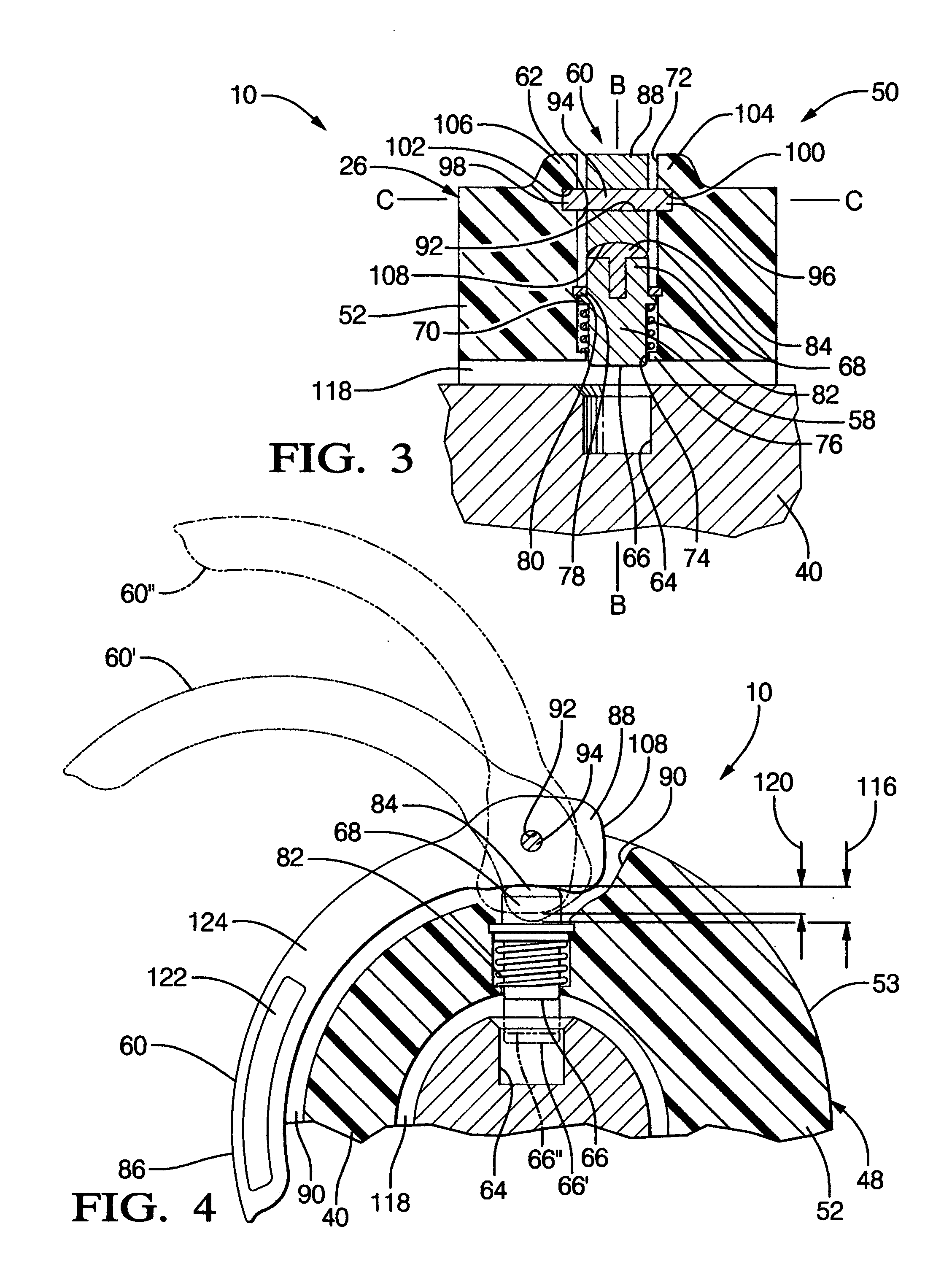

[0025]For purposes of illustration, the present invention is implemented within a specific type of hand-held power tool, in particular, a hand-held industrial grinder. However, it can be applied with equal success with other commercial or light duty hand-held power tool types such as a circular saw, drill, screw driver, or the like. is carried with the housing assembly which is selectively displacable along a fixed axis between a locked position in which a first end portion of the lock member engages a rotating element of the drive train to prevent rotation of the spindle, and a released position in which the first end portion of the lock member is spaced from the rotating element to permit rotation of the spindle. Resilient means, such as a compression spring, continuously urges the lock member toward the released position to provide fail-safe operation. Finally, a lever is carried externally of the housing assembly and engages the lock member. The lever is manually operable to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com