Screw compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

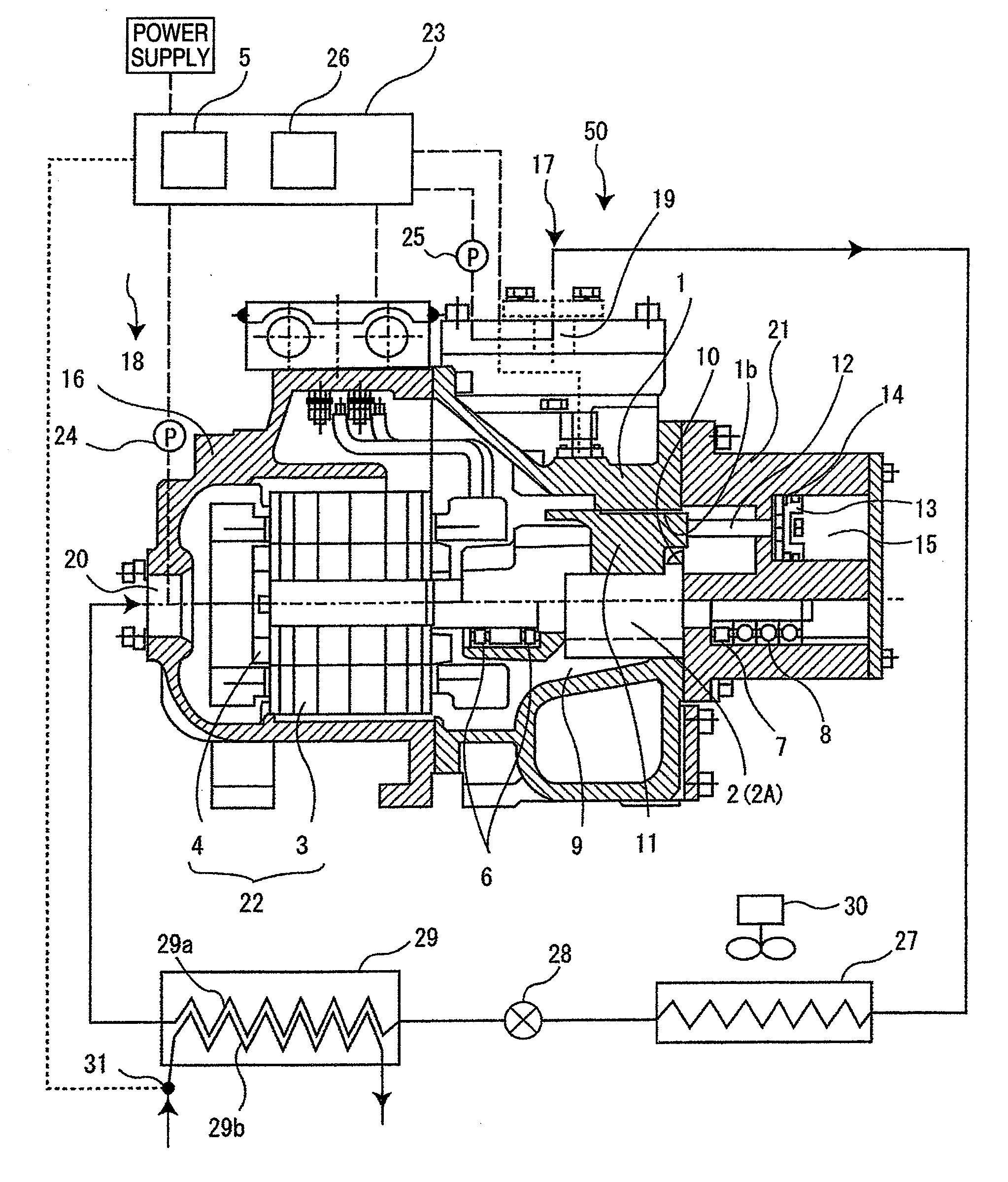

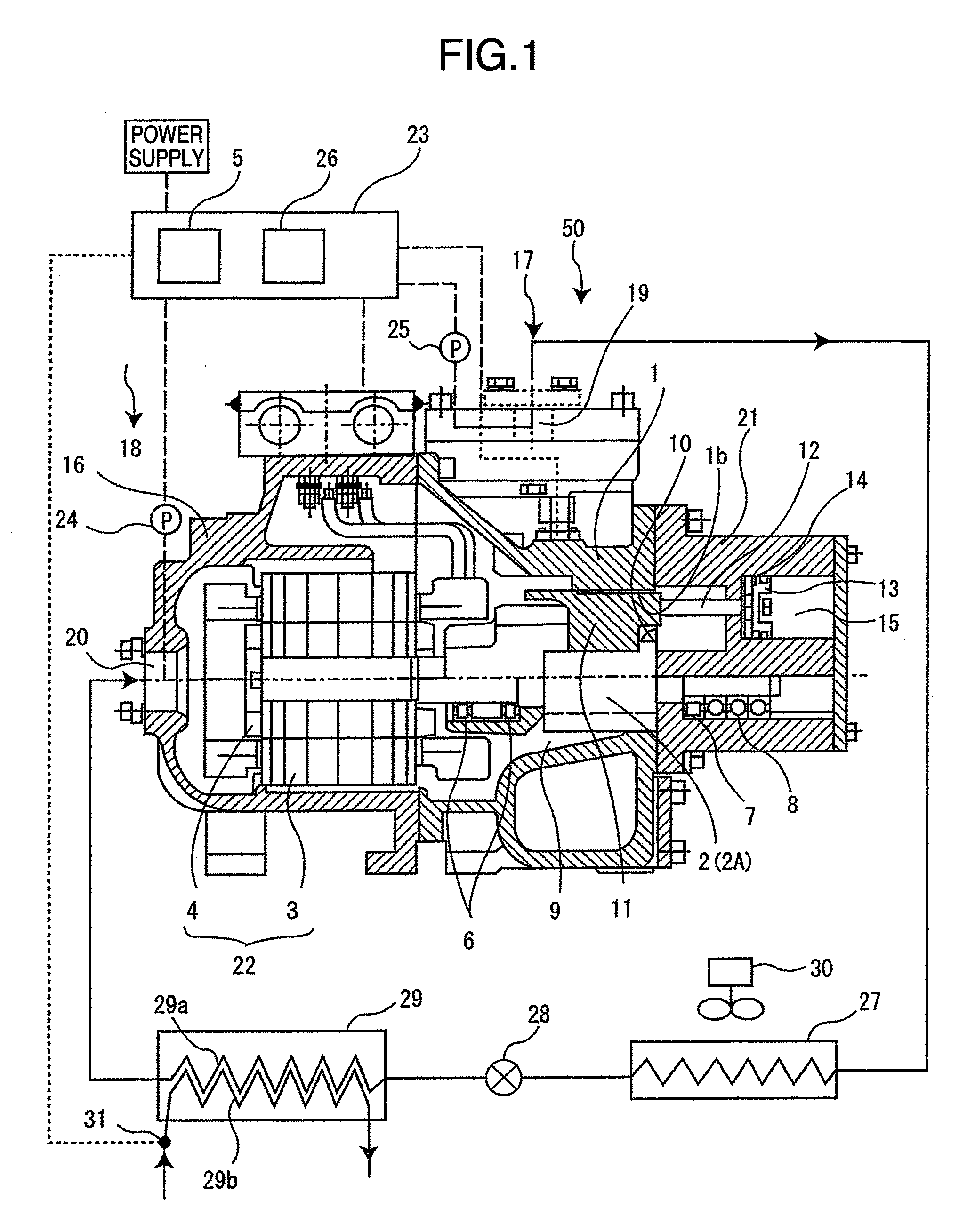

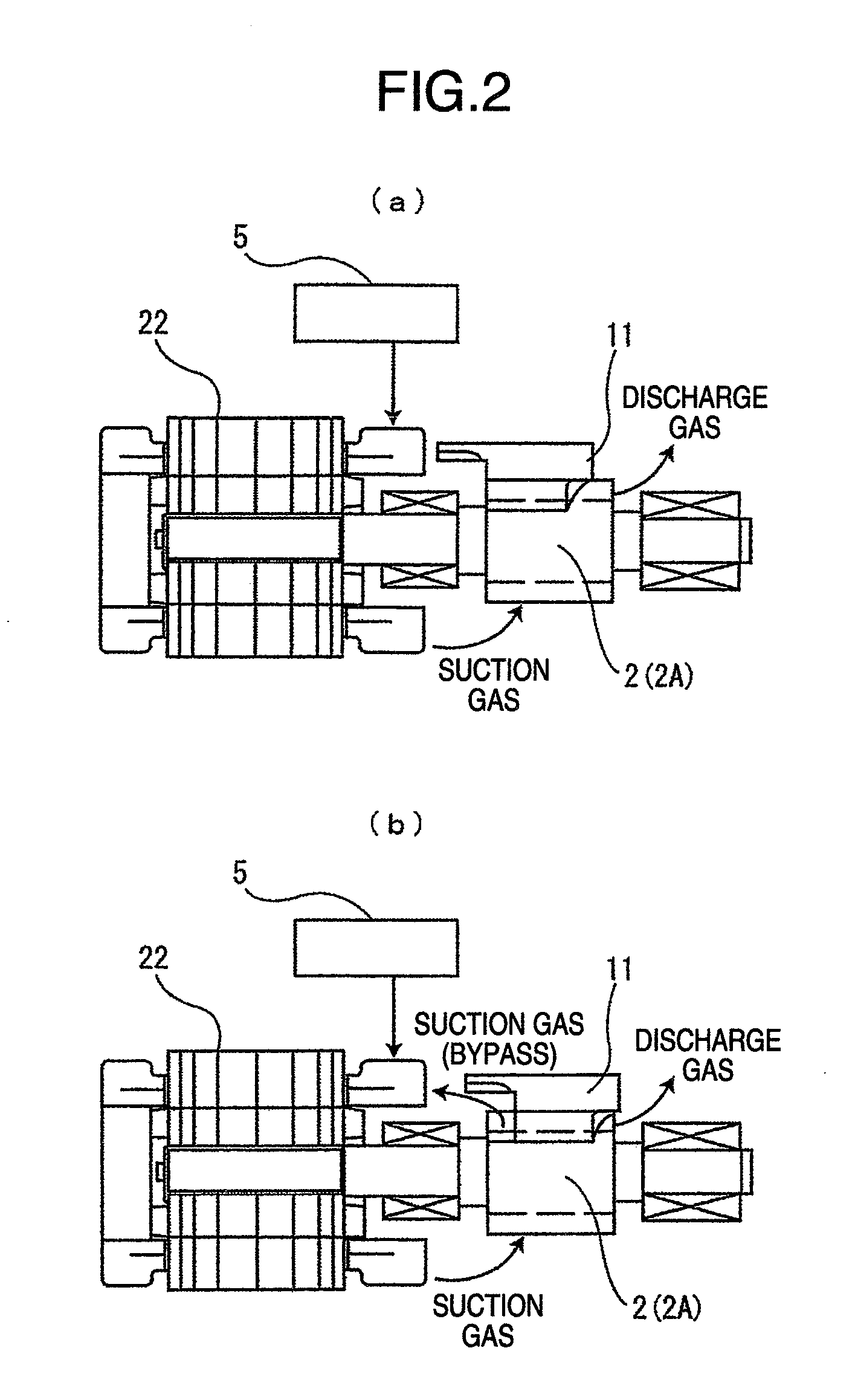

[0019]Hereinafter, one embodiment of the present invention will be described with reference to FIGS. 1 to 3. FIG. 1 is a sectional view of a screw compressor showing an embodiment of the present invention, FIG. 2 is an operation explanatory view of a capacity control valve in FIG. 1, and FIG. 3 is a view showing a characteristic curve of compressor efficiency relative to refrigerating capacity ratio in the screw compressor of FIG. 1.

[0020]A screw compressor 50 is constituted by a screw compressor for a screw chiller comprising a compressor portion 17, a motor portion 18 and a control device 23. Refrigerant gas to be compressed flows to the compressor portion 17 through the motor portion 18, and after being compressed by the compressor portion 17, is discharged outside the compressor. While the screw compressor 50 performing a capacity control operates in such a manner that the rotational speed and the position of a capacity control valve are changed so that pressure becomes constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com