Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

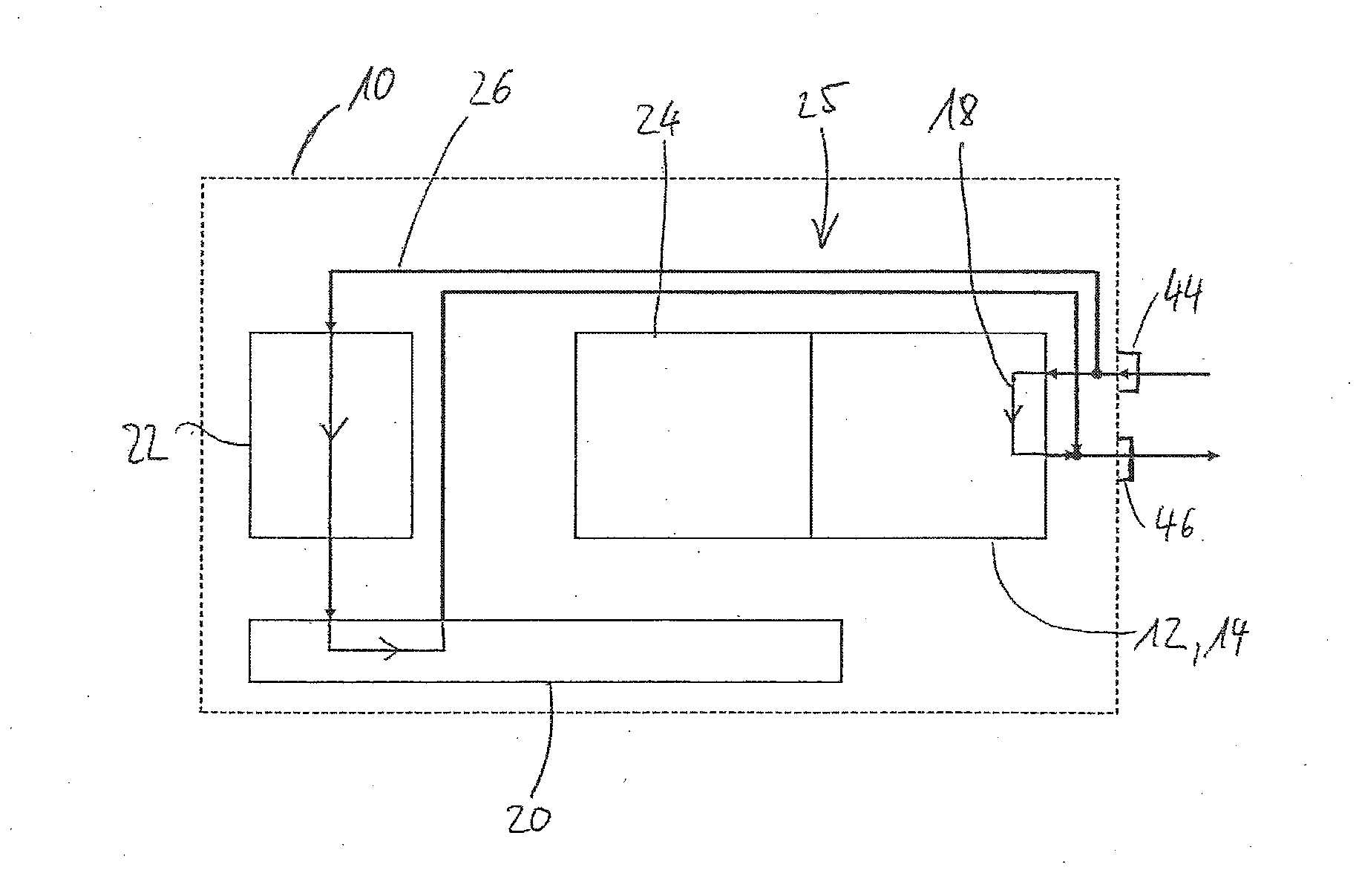

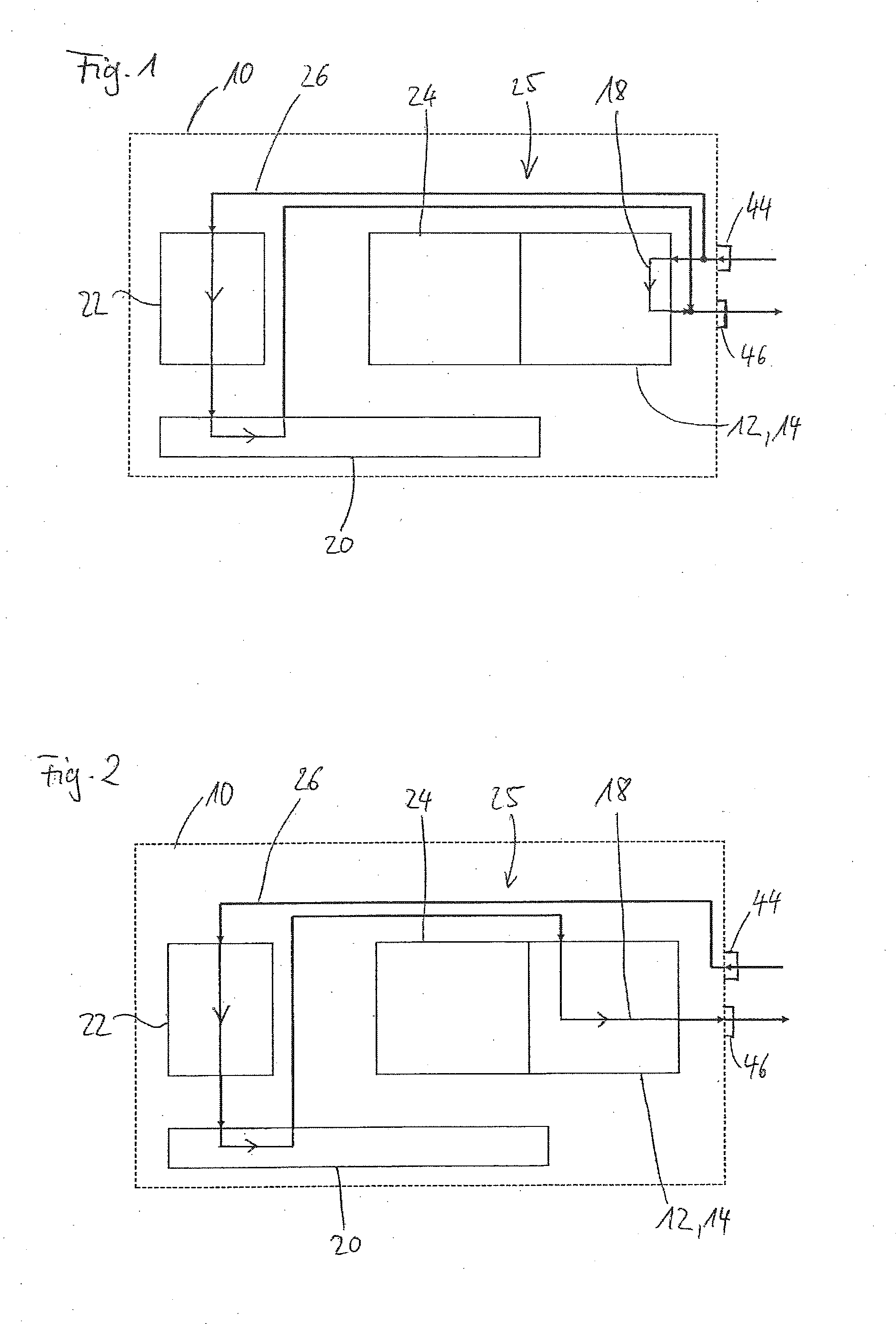

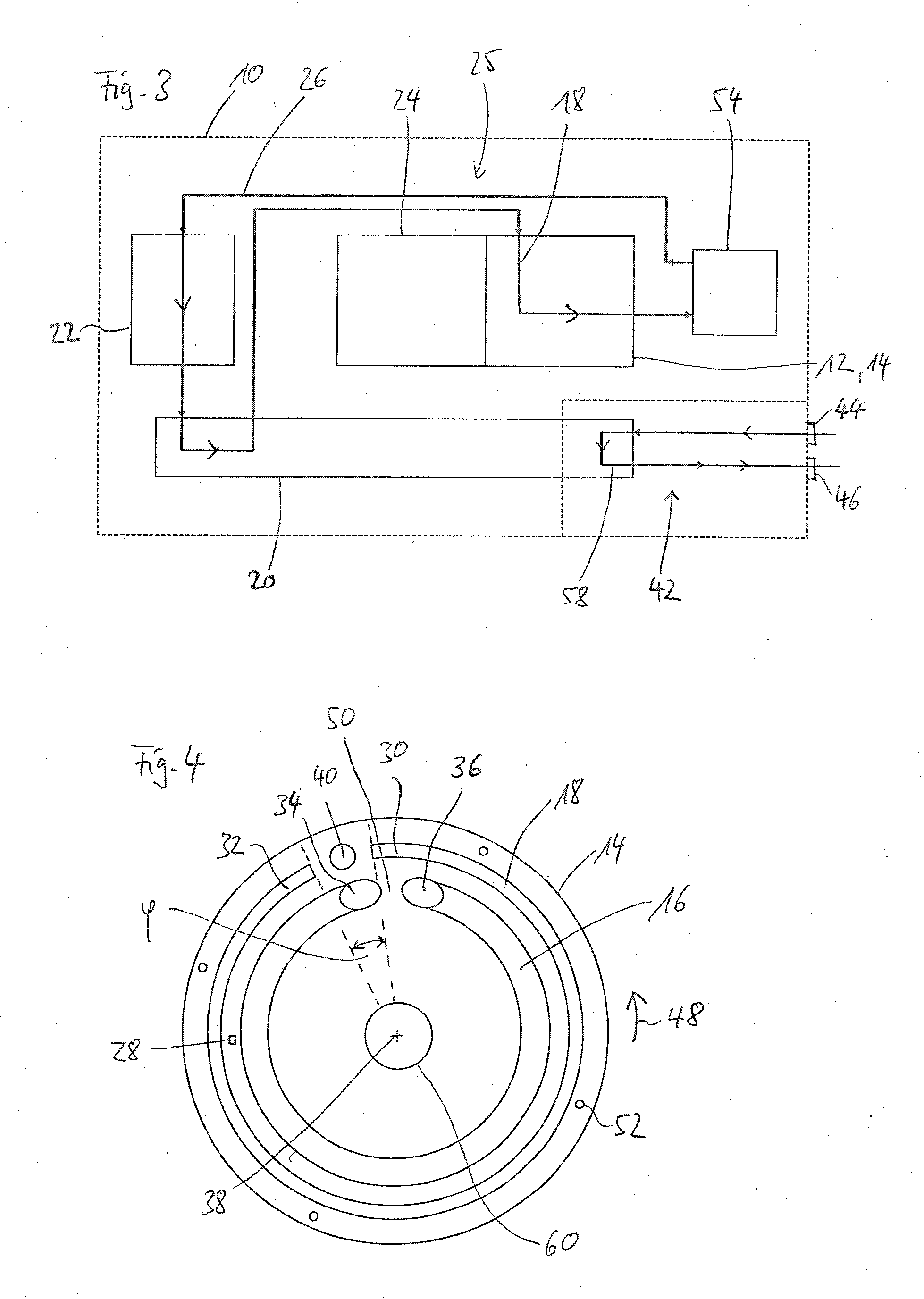

[0062]FIG. 1 shows a vacuum pump 10 in accordance with an embodiment of the invention in a schematic representation. The vacuum pump 10 comprises a side passage pump stage 12 which has at least one stator element 14, an electric motor 22 for the rotational driving of a rotor element of the side passage pump stage 12, a cooling plate having drive electronics 20 arranged thereon for the motor 22 and a high vacuum pump stage 24.

[0063]The pump 10 furthermore comprises a coolant circuit 25 which comprises a coolant inlet 44 accessible from outside the pump 10 and a coolant outlet 46 of the vacuum pump 10 accessible from outside the pump 10, wherein the inlet 44 and the outlet 46 are connected to one another in a coolant conducting manner via coolant passages 18, 26 of the coolant circuit 25. The arrow tips in FIG. 1 characterize the coolant flow direction from the inlet 44 to the outlet 46.

[0064]The coolant passage 18 serves for the cooling of the side passage pump stage 12 and is bounde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com