Precursors and hardware for CVD and ald

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

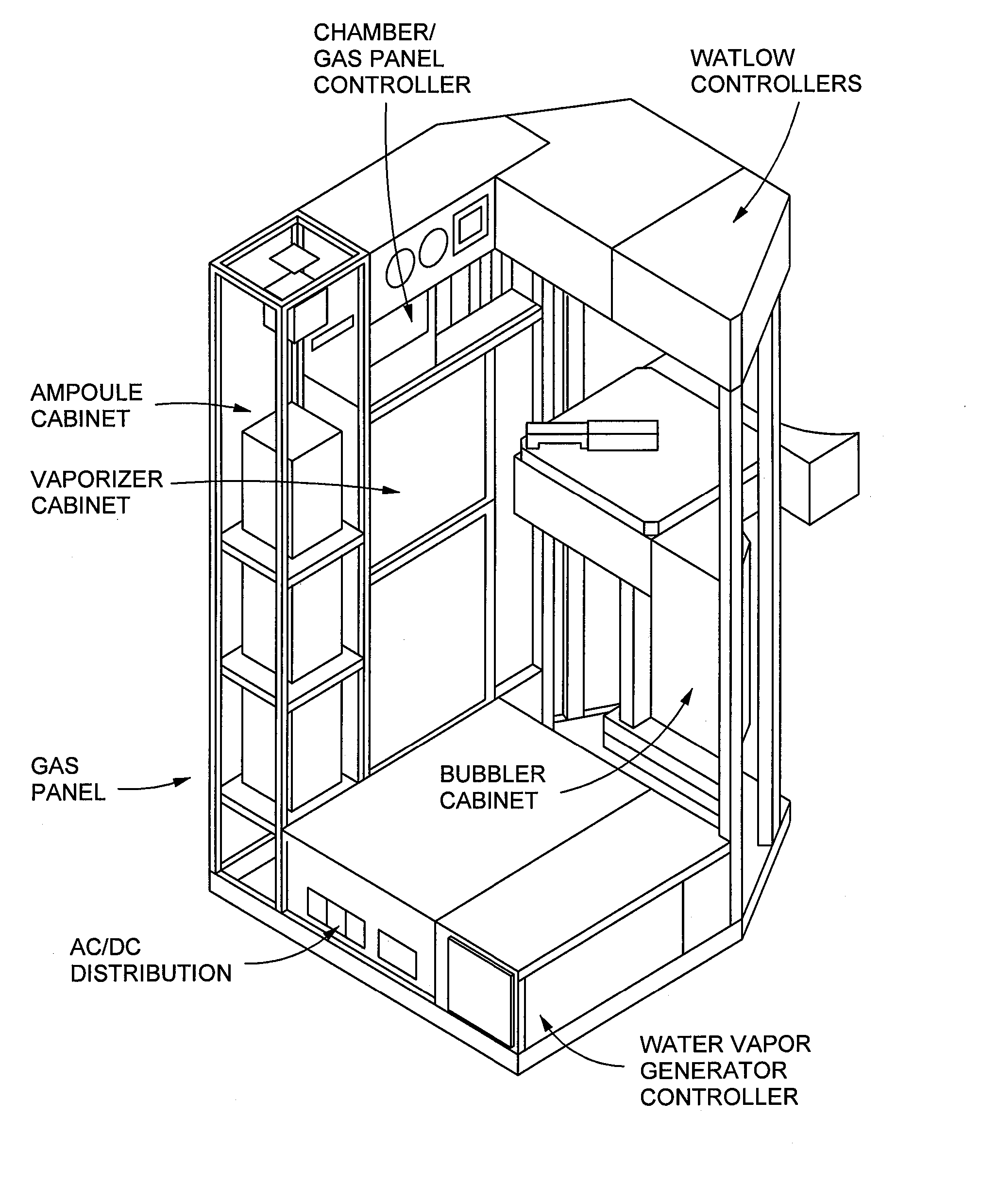

[0017] The present invention generally comprises an apparatus for depositing high k dielectric materials or metal gate materials in which toxic, flammable, or pyrophoric precursors may be used. Exhaust conduits may be placed on the liquid precursor or solid precursor delivery cabinet, the gas panel, and the water vapor generator area. The exhaust conduits permit a technician to access the apparatus without undue exposure to toxic, pyrophoric, or flammable gases that may collect within the liquid precursor or solid precursor delivery cabinet, gas panel, and water vapor generator area. Exemplary high k dielectric material that may be deposited include HfO2, HfSiO, Pr2O3, La2O5, ZrO2, ZrSiO, Al2O3, LaAlO, Ta2O5, TaO5, AlO5, and TiO5. Exemplary metal gate materials that may be deposited include TaN, TiN, TaSiN, Ru, Pt, TiAlN, and HfN. Other films may also be deposited including polysilicon, SiN, and HTO. The apparatus may be an ALD reactor or a CVD reactor.

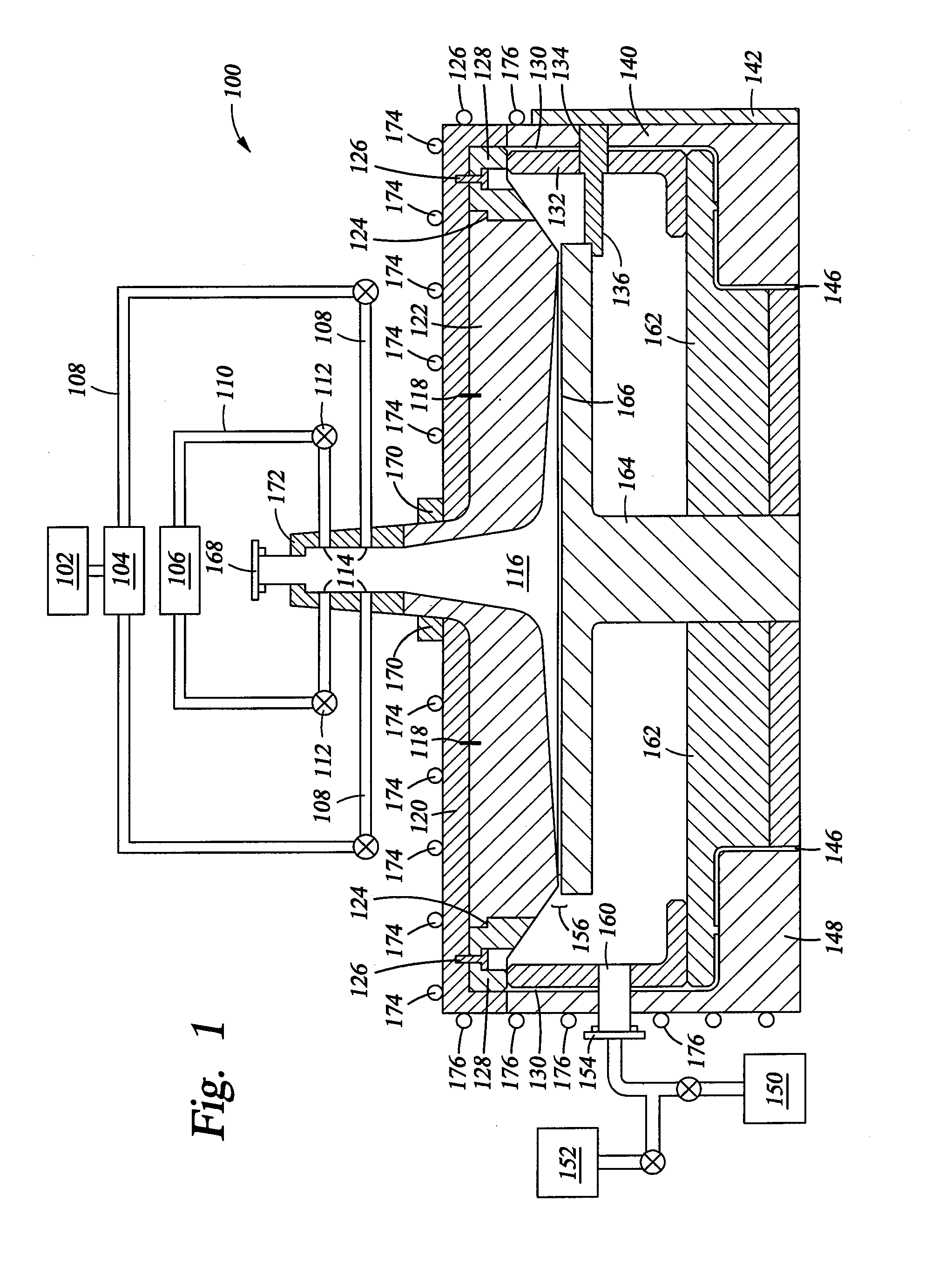

[0018]FIG. 1 depicts a schema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flammability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com