System and Method for Budgeting, Planning, and Supply Chain Management

a supply chain management and planning system technology, applied in the field of system and method for data processing and forecasting refinement, can solve the problems of reducing the optimality of the solution, reducing the efficiency of the solution, so as to reduce the total prior art administrative cost and avoid missed profit opportunities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

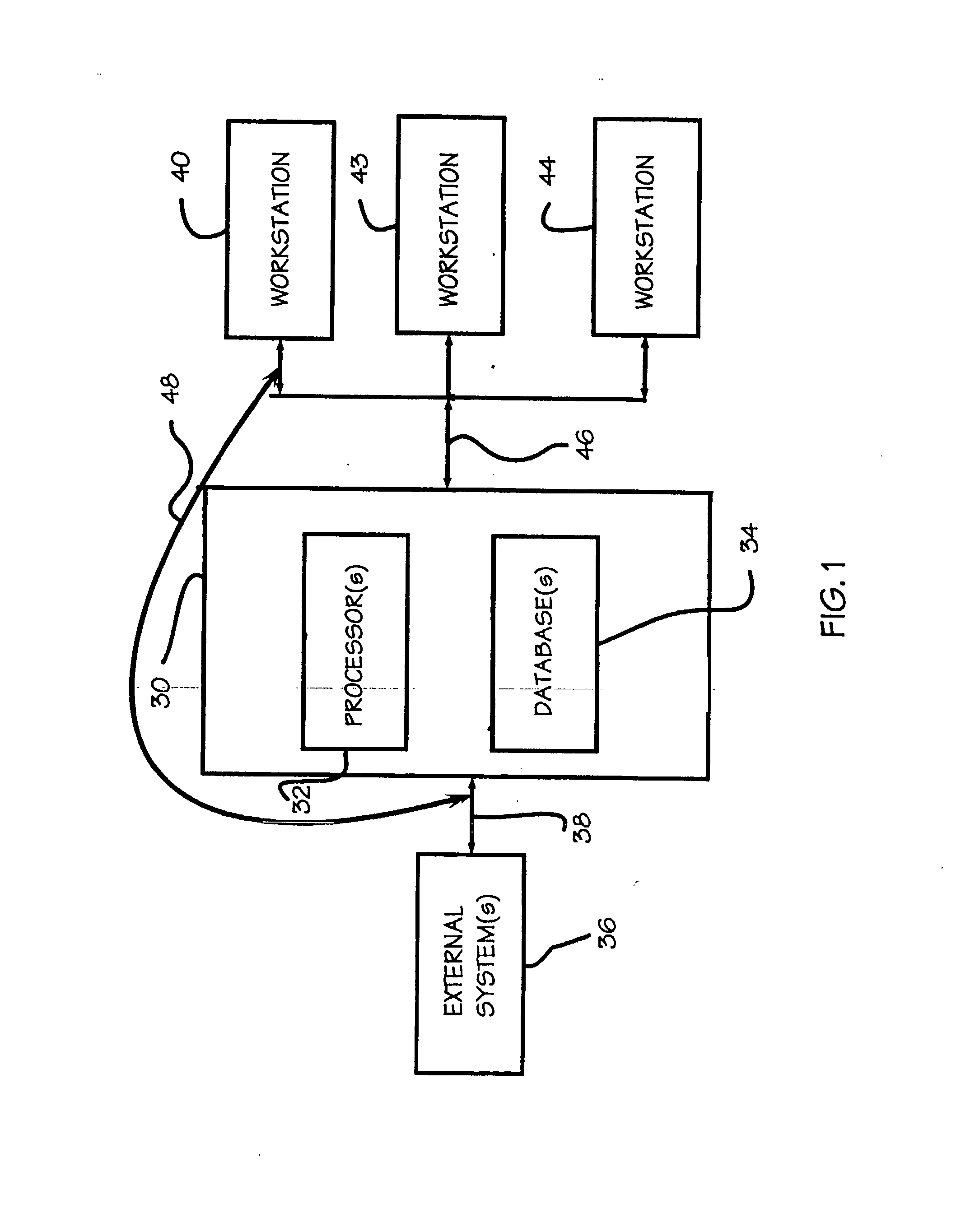

[0067] Referring now to FIG. 1, there is shown a block diagram of one embodiment of the system according to the present invention. In this embodiment, the system comprises computer 30, external system(s) 36, first workstation 40, second workstation 42, third workstation 44, first network 38 and second network 46. Computer 30 comprises processor(s) 32 and database(s) 34 used to execute the method of the present invention, and to hold the data used and generated by the present invention, respectively. Computer 30 may comprise the combination of one or more computing device, including but not limited to one or more personal computers, one or more servers, or a combination of processors and databases connected for operation as a unit. External system(s) 36 comprise one or more systems having data of use to computer 30. External system(s) 36 are optional, as computer 30 may hold all of the data used by computer 30 for the present invention. An example of an external system may be a suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com