Sealing of variable guide vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The sealing of variable guide vanes, according to the disclosure, can be used on all turbomachines with guiding devices, for example exhaust gas turbochargers, power turbines, gas turbines or compressors, with variable guide vanes.

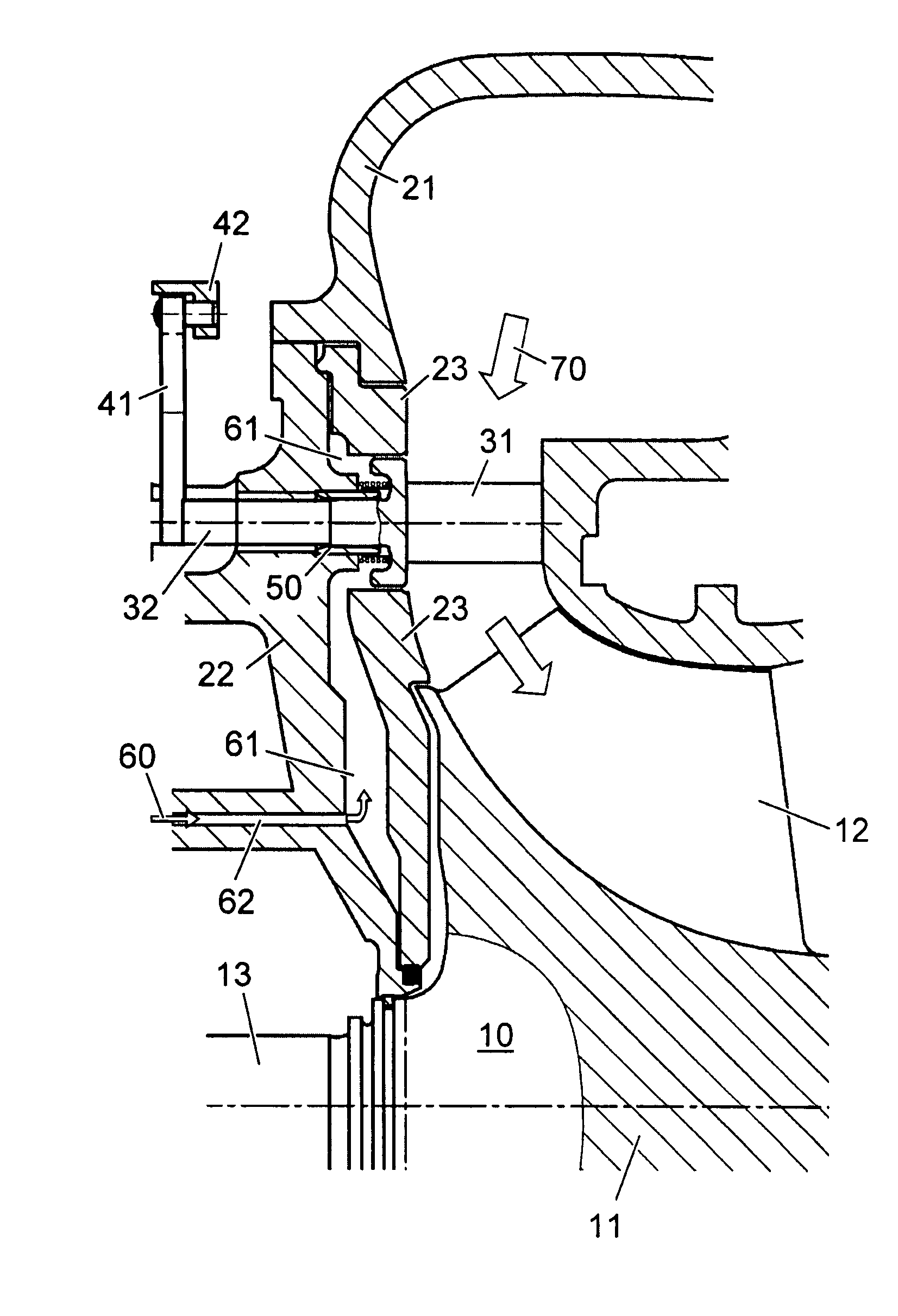

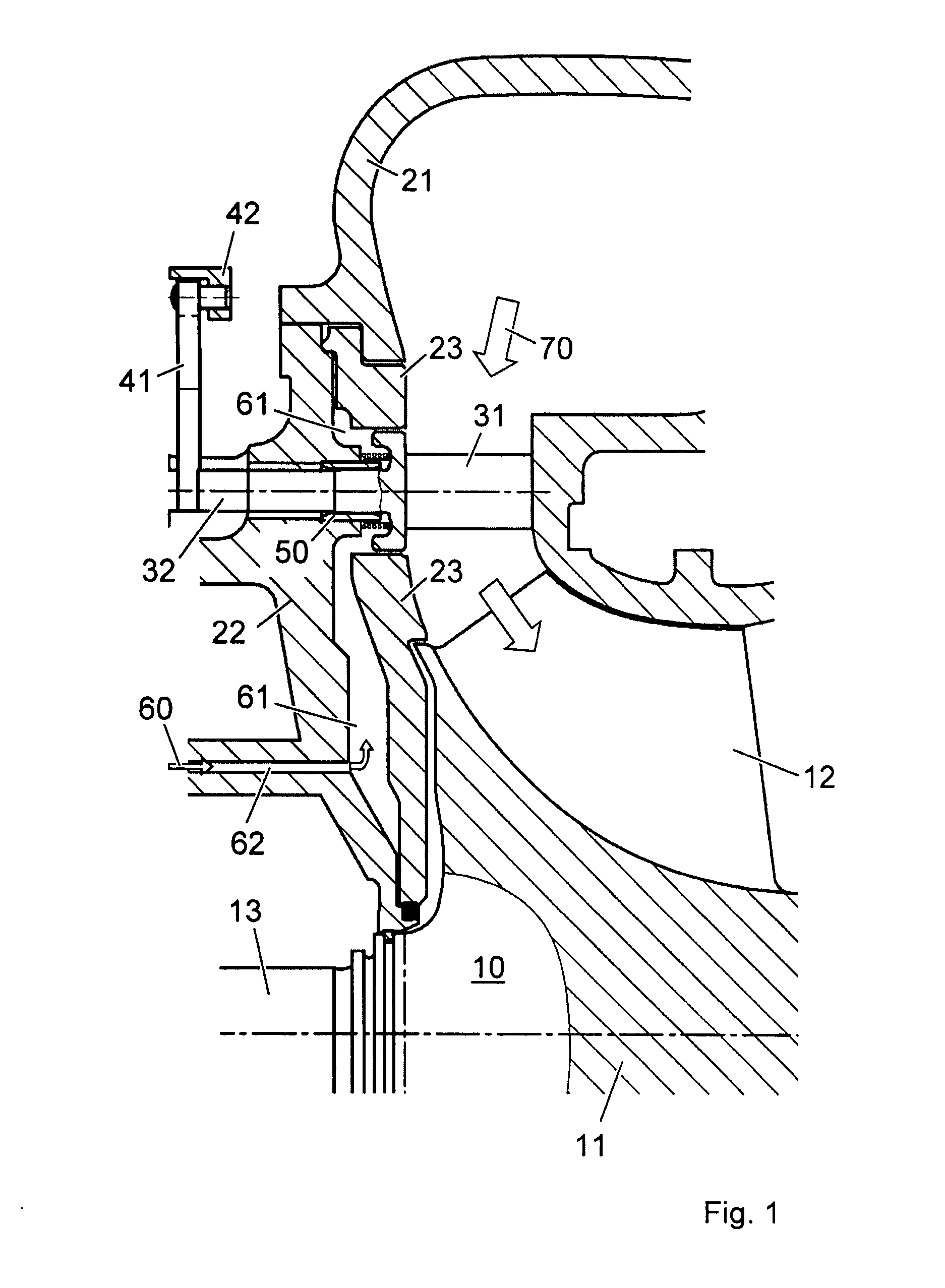

[0015]FIG. 1 shows the turbine side of an exhaust gas turbocharger with a turbine wheel 10 which is arranged in a turbine housing. The turbine wheel comprises a hub 11 and rotor blades 12 which are fastened upon it or manufactured integrally with the hub. The turbine housing comprises a gas inlet housing 21, a bearing housing 22, and also a partition 23 in the back of the hub of the turbine wheel. The partition serves for the thermal shielding of the bearing housing from the hot turbine wheel. It can alternatively also be formed by parts of the bearing housing or the gas inlet housing.

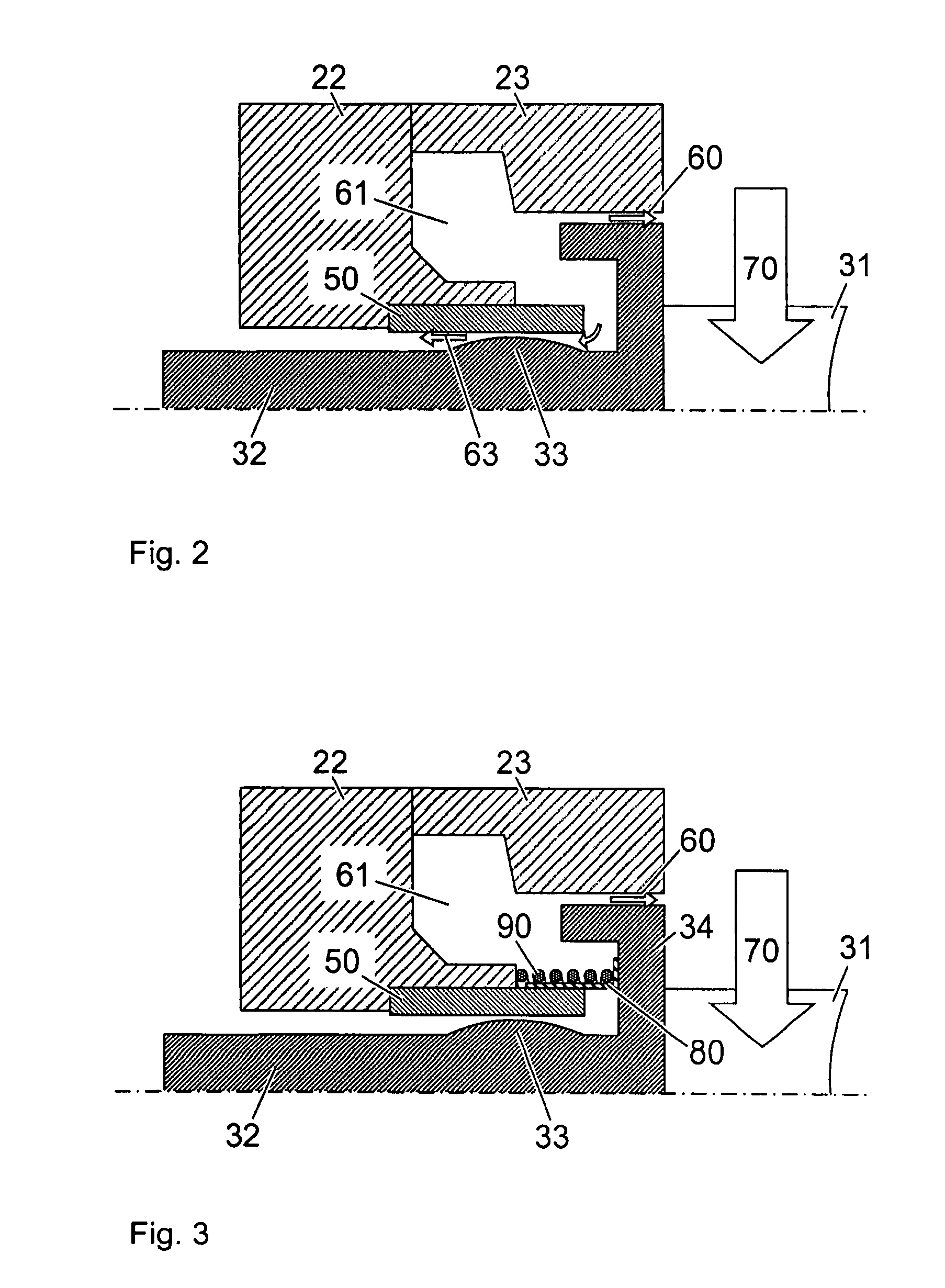

[0016] A guiding device is arranged in the flow passage which leads to the rotor blades. The guiding device comprises variable guide vanes 31 for controlling the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com