Graham Power, a new method of generating power

a new generation method and power technology, applied in steam engine plants, machines/engines, mechanical equipment, etc., can solve the problems of reducing the efficiency of the compression process, affecting the efficiency of the turbine, the generator and the motor, and the inability to meet the needs of the operation, so as to reduce the cost of air conditioning and the effect of useful power and revolutionizing the generation of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

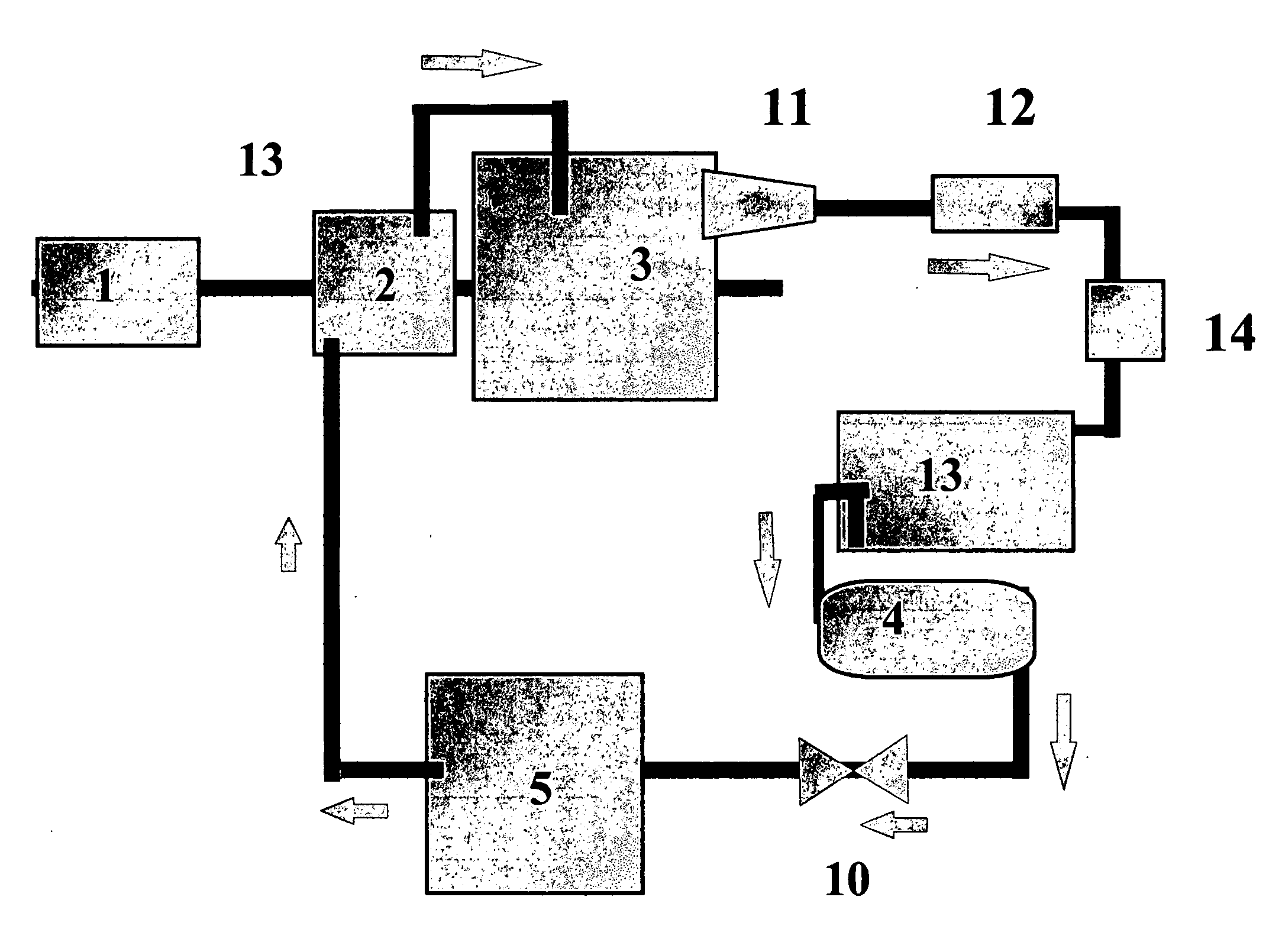

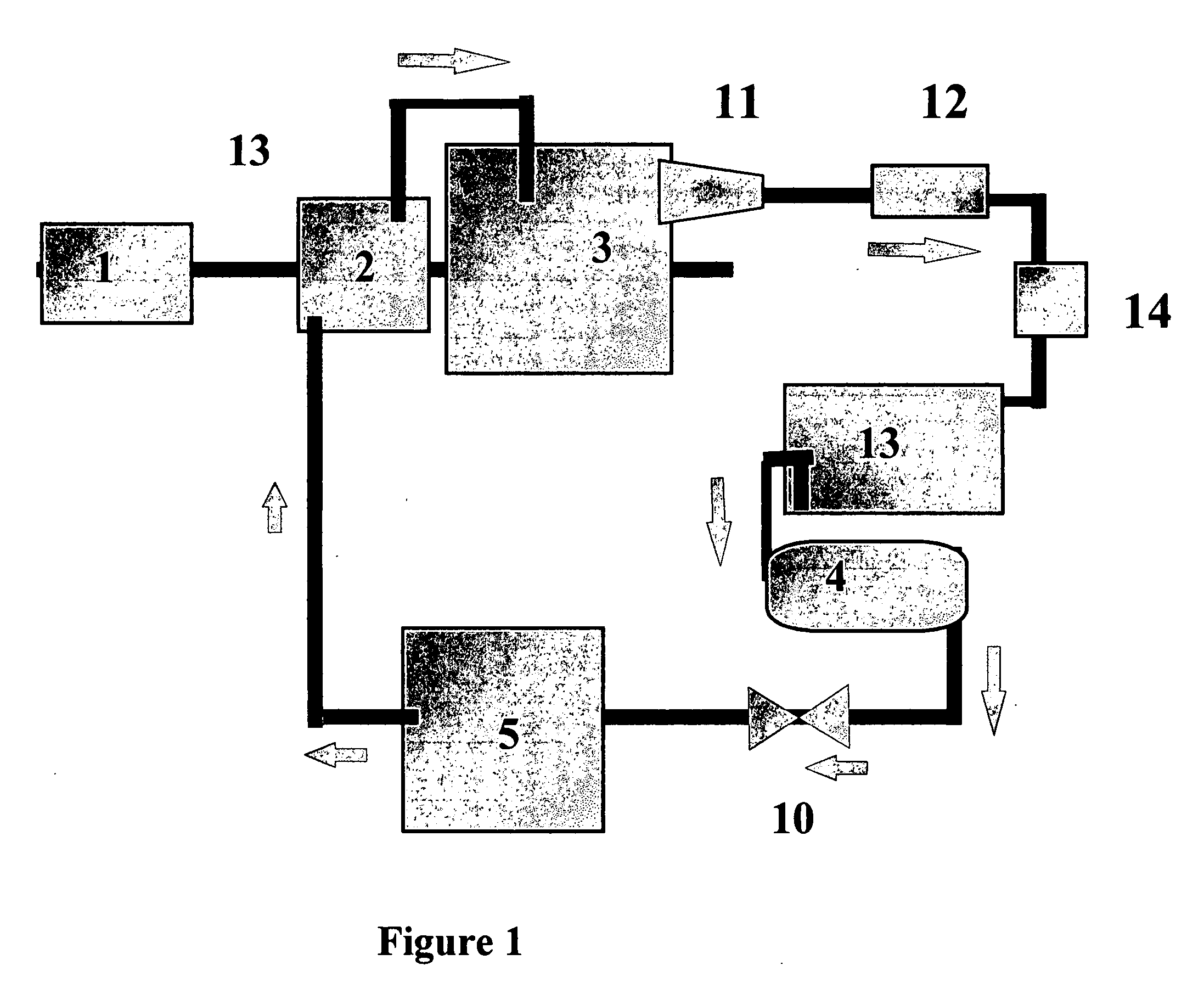

[0013]FIG. 1 embodies a concept of this invention. Motor / generator 1 is connected by common shaft 13 to compressor 2 and turbine 3. These three components work as follows. When the motor / generator 1 is turned on, valve 10 is opened and motor / generator 1 drives compressor 2 and turbine 3. As the expanding refrigerant gas begins to drive turbine 3, less power is drawn from motor / generator 1. Once turbine 3 generates sufficient power to drive the compressor 2 no power is drawn from motor / generator 1. When turbine 3 generates more power than compressor 2 requires the motor / generator 1 will produce electricity which is feed back into the electrical grid. In most applications the motor / generator 1 will be two separate units, a motor and a generator connected to shaft 13. The embodiment of motor / generator 1 contained herein is designed to convey the concept rather than the engineering details.

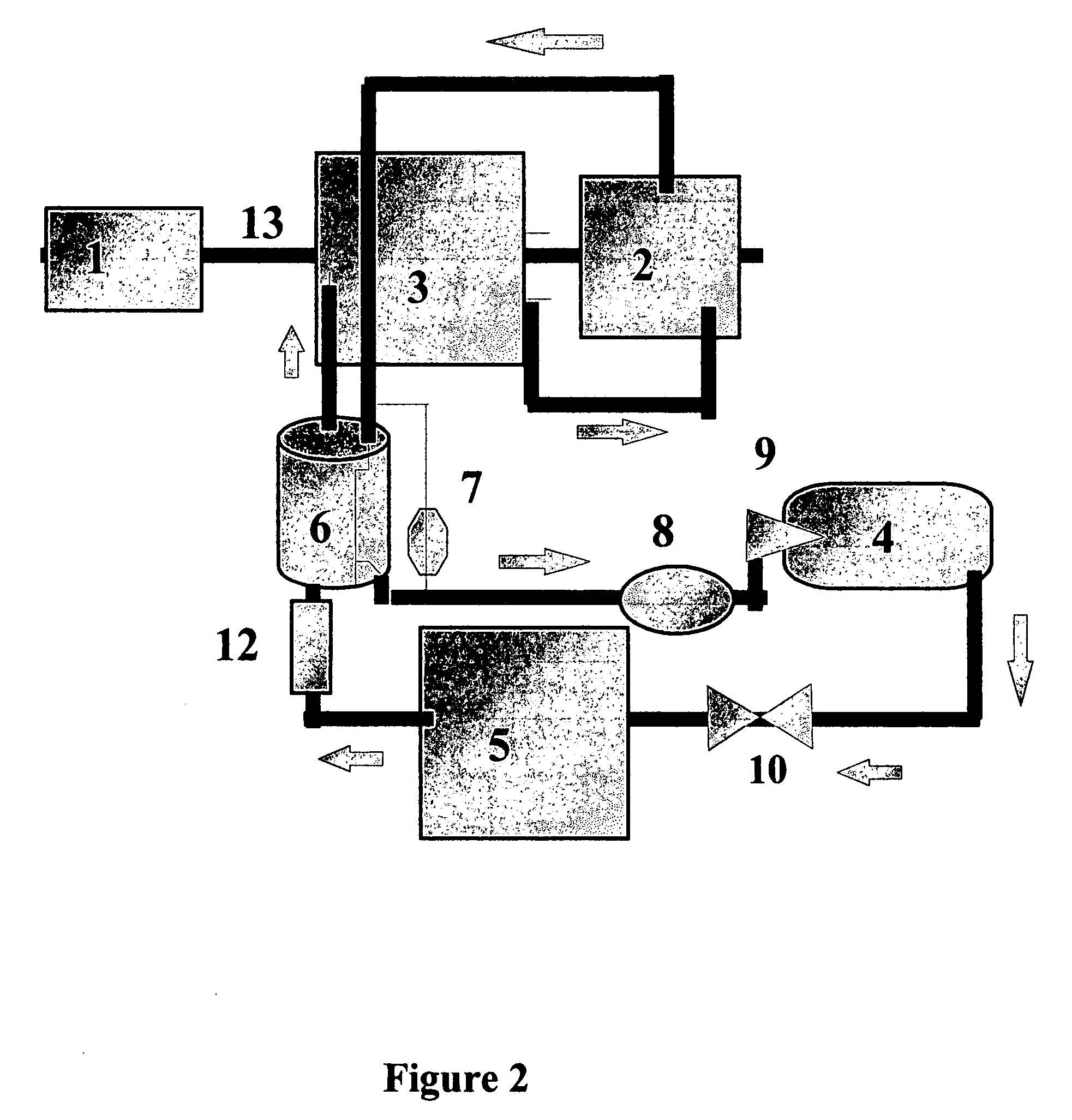

[0014] The arrows indicate the flow of refrigerant through the system as follows. Storage tank 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com