Bubble mailer chill pack envelope

a mailer and envelope technology, applied in the field of bubble mailer chill pack envelope, can solve the problems of low high cost of individual medical shipments, etc., and achieve the effects of reducing the cost of cold temperature packaging, and reducing the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

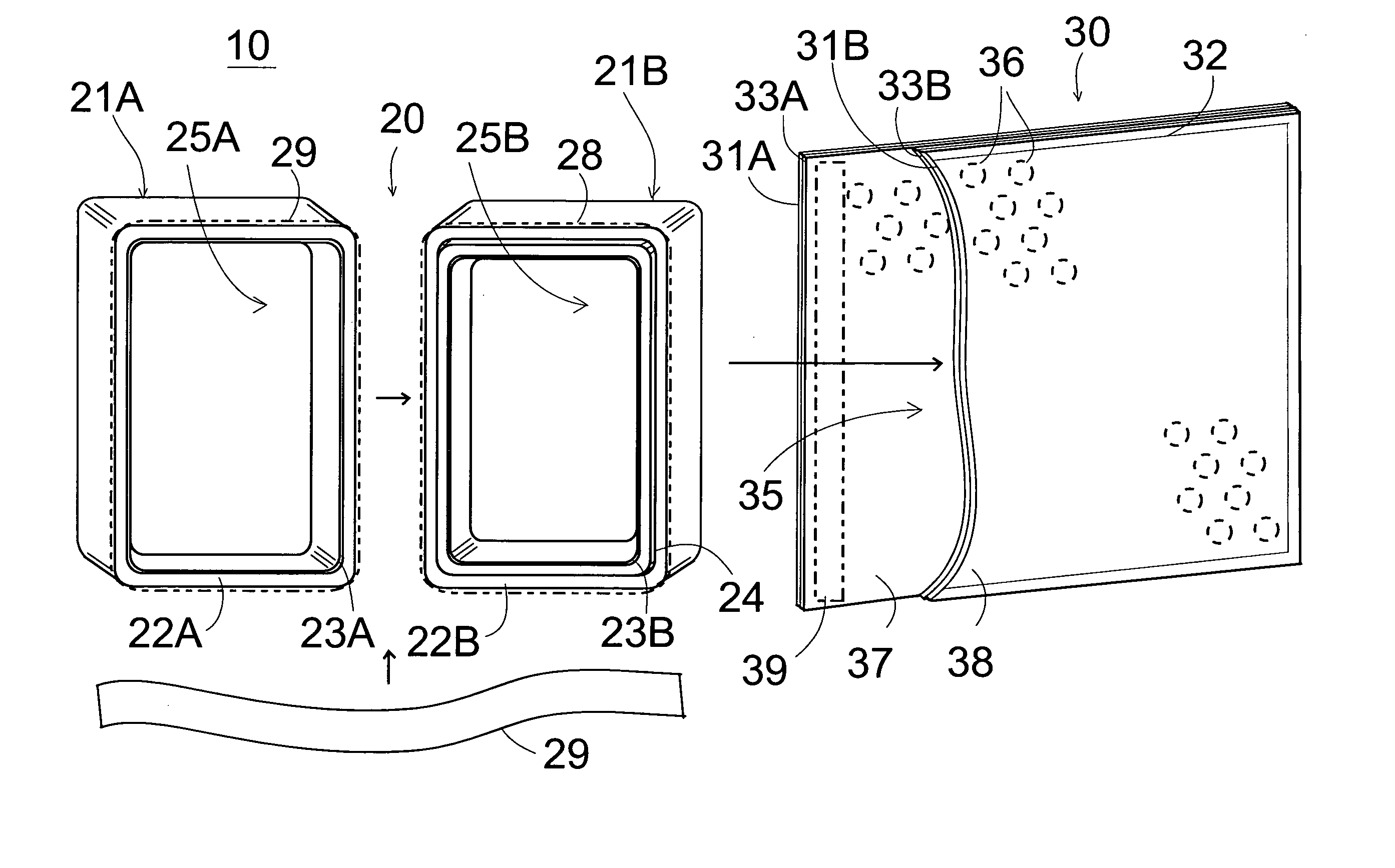

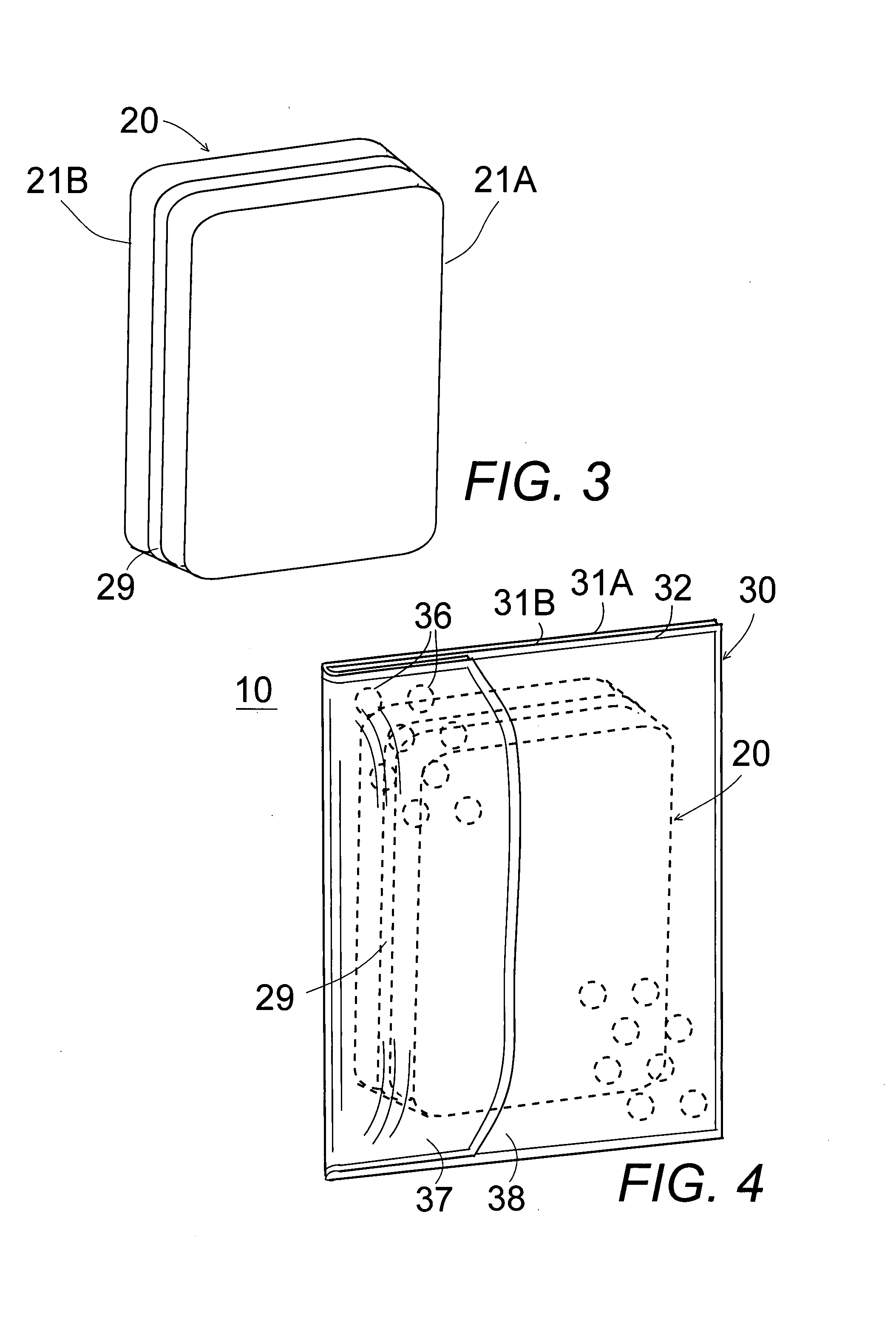

[0037] In FIGS. 1-4, a temperature insulated shock resistant mailer system 10 comprising in combination an outer bubble wrap mailer envelope 30 and an inner thermal container 20.

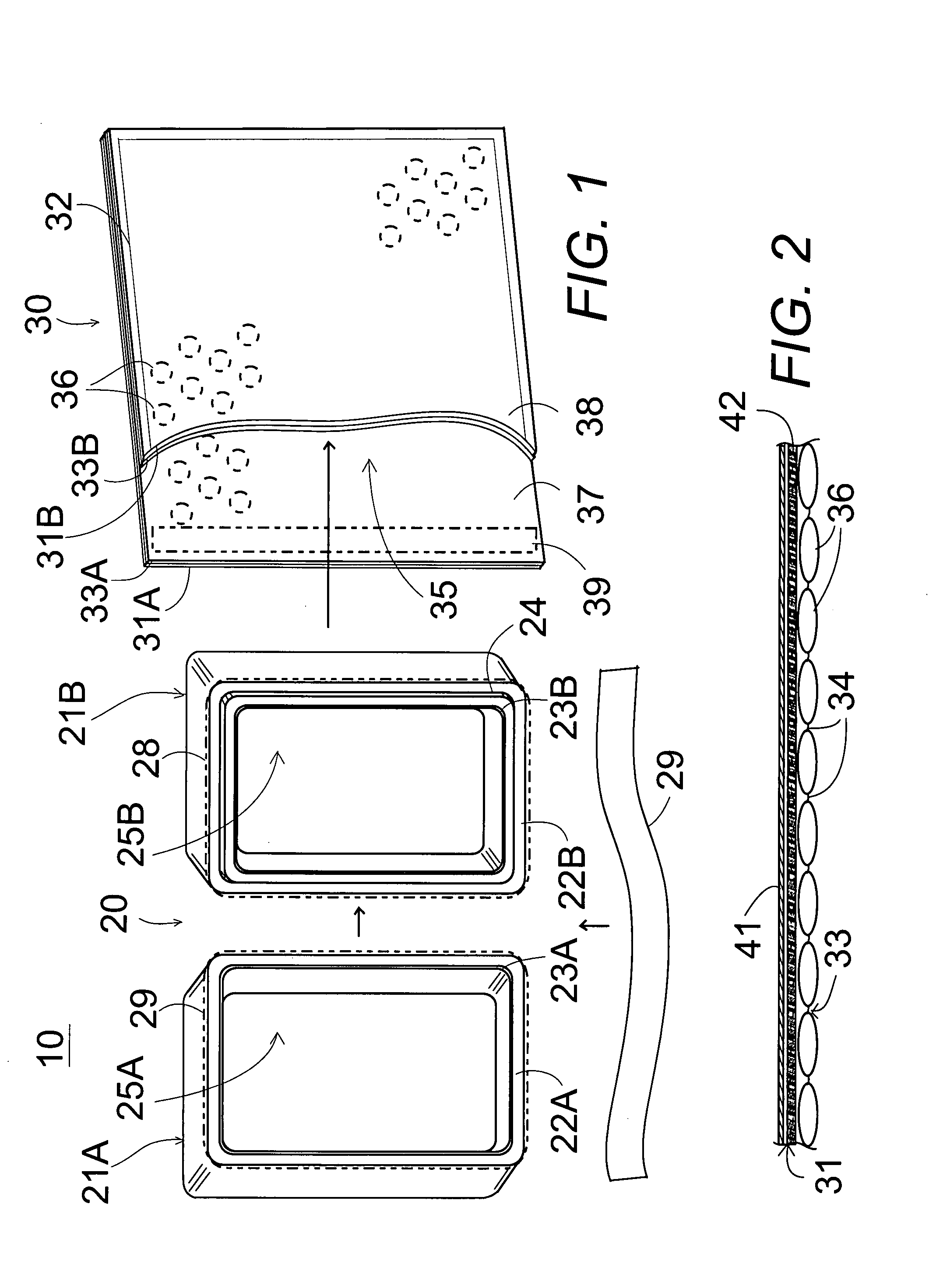

[0038] In FIGS. 1 and 2, the outer bubble wrap mailer envelope 30 comprises a top sheet 31B and a bottom sheet 31A, each sheet 31 having bubble wrap material 33 with insulating and shock absorbing air bubbles 36 interconnected by plastic sheeting 34, as shown in FIG. 2. The two sheets 31A and 31B are heat sealed together to form a seam 32 around the periphery of the two sheets with an opening 35 at one end. The top and bottom sheets 31A and 31B of bubble wrap provide a shock resistant cushion for contents of the bubble wrap mailer envelope as well as thermal insulation for the contents.

[0039] In FIG. 2, a temperature insulating moisture barrier and puncture barrier, such as a combined layer of PERLITE 42 adhered to the bubble wrap 33 with a sealing MYLAR layer 41 to lock the layer of PERLITE in place, are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Thermal properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com