Protective cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

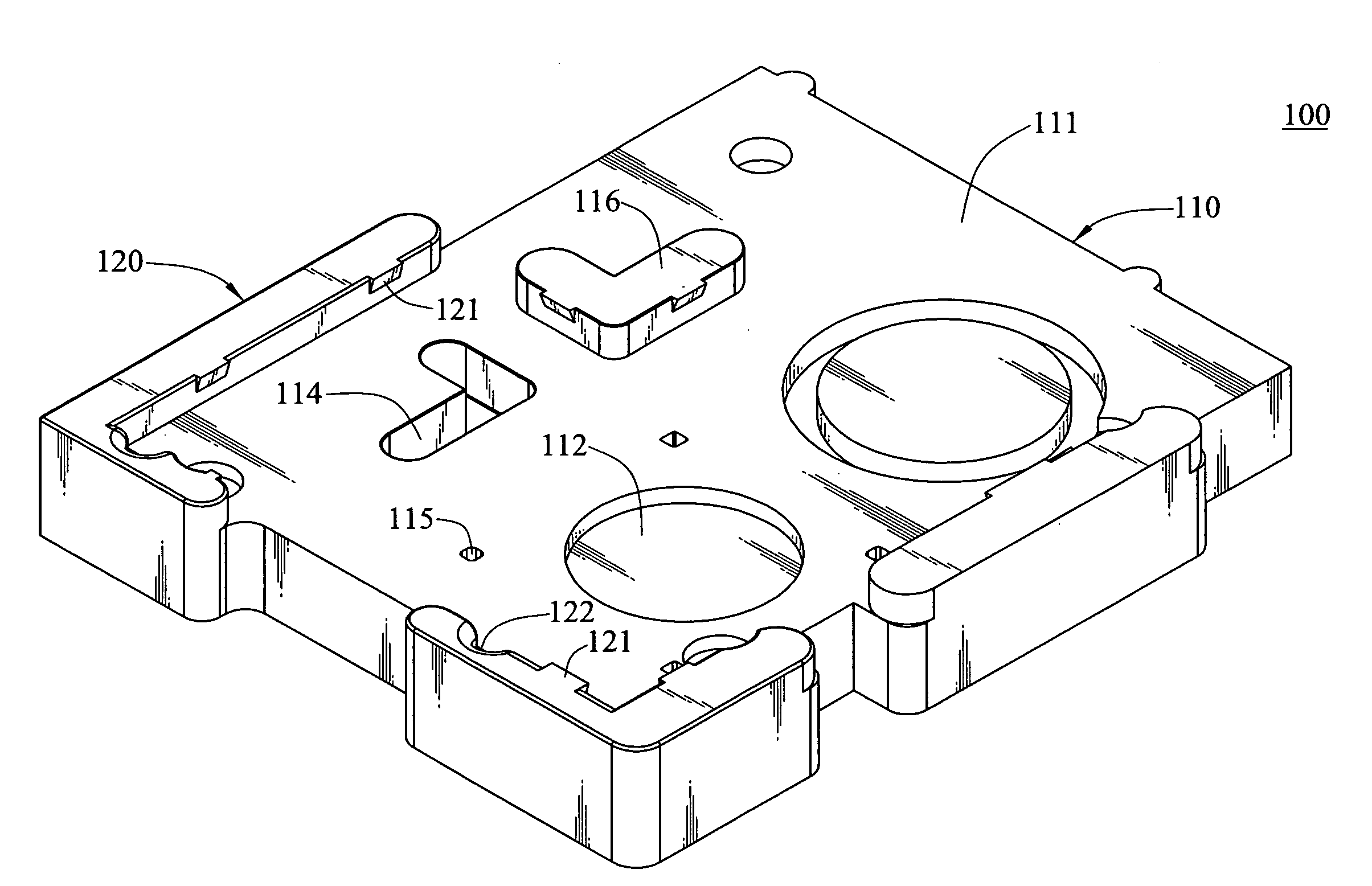

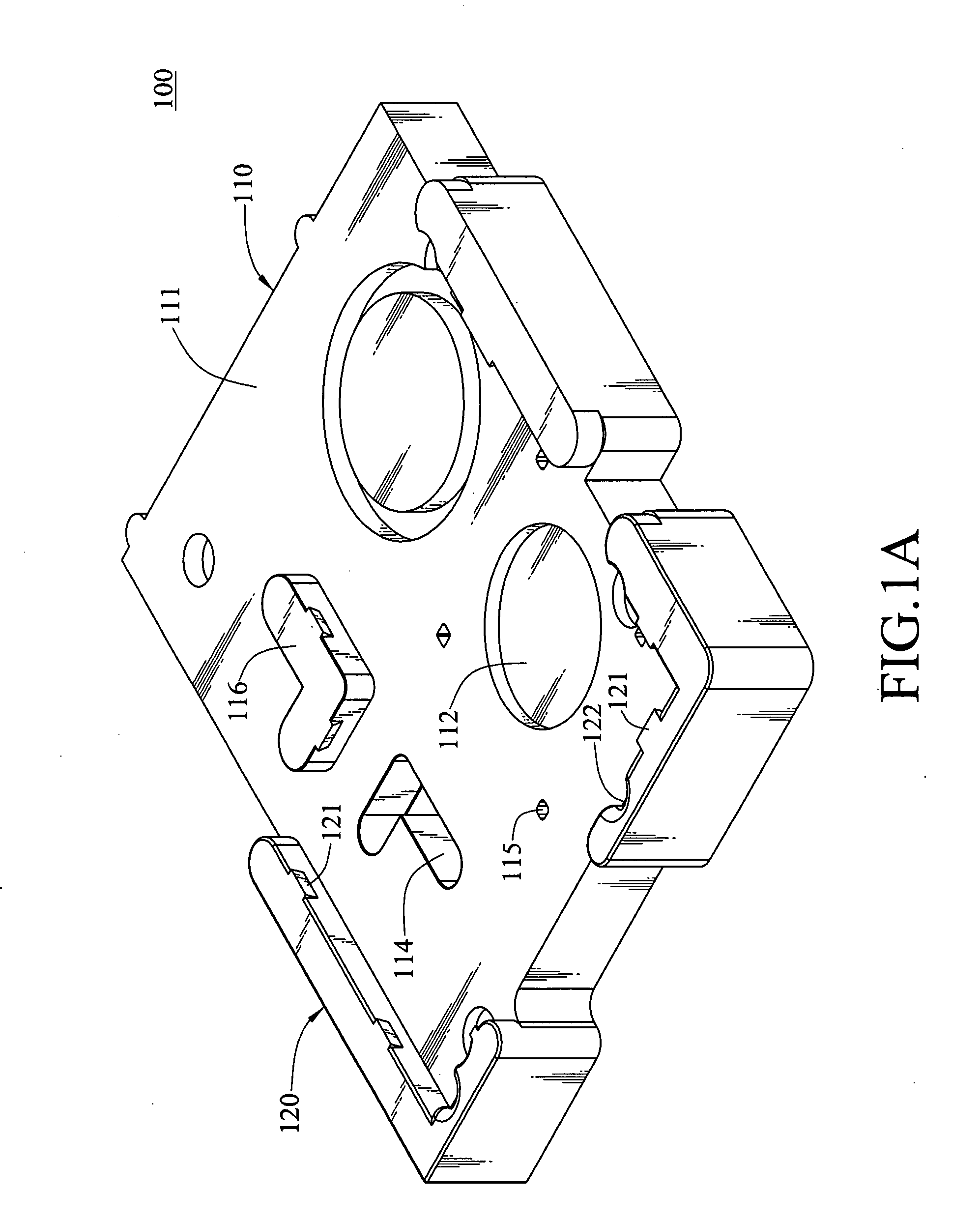

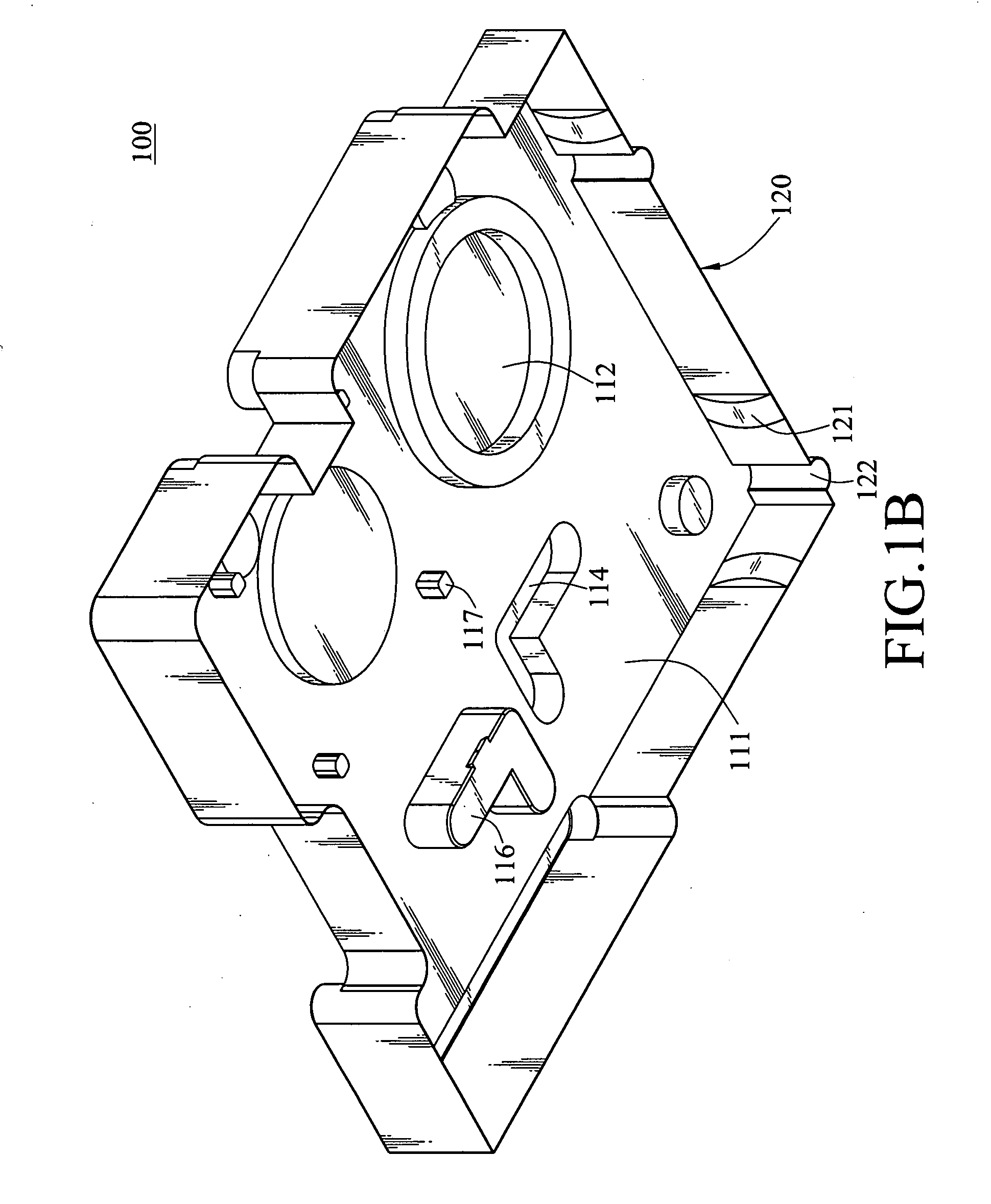

[0036]FIGS. 1A to 1F are schematic views of the present invention. As shown in the figures, the protective cover 100 provided by the present invention may simultaneously protect the thermal conducting mediums 210 coated on the bottoms of two heat sinks 200, so as to protect the thermal conducting mediums 210 from being contaminated or peeling off. The protective cover 100 of the present invention includes a plate body 110 and two holding portions 120. The plate body 110 has two opposite plate surfaces 111 respectively covering the bottoms of the two heat sinks 200 coated with the thermal conducting medium 210. One side of the plate body 110 is designed to be a frame structure with an accommodation space, so a side wall extends vertically to the periphery of one plate surface 111, thereby forming a holding portion 120. A side wall is protruded from the edge of the other side of the plate body 110, so as to form another holding portion 120 at the side of the other plate surface 111. T...

second embodiment

[0039]FIGS. 2A to 2F are schematic views of the present invention. The plate body 110 of the present invention has two opposite plate surfaces having a plurality of columnar support members 113 protruding therefrom. When the plate body 110 covers the bottoms of the two heat sinks 200, the top ends of the support members 113 rest on the bottoms of the heat sinks 200, so that the thermal conducting medium 210 may be accommodated in the space between the support members 113 and the plate surface 111, and is separated from the plate surface 111 by a distance without contacting the plate surface 111.

[0040]Referring to FIGS. 2A to 2F, a plurality of recess holes 115 corresponding to the support members 113 on one plate surface 111 is formed on the plate surface 111 on the other side. Moreover, an L-shaped recess portion 114 corresponding to the size of the heat sinks 200 is formed on the plate surfaces 111 respectively, so that the protruding portions of the heat sinks 200 may be engaged ...

third embodiment

[0041]FIGS. 3A to 3G are schematic views of the present invention. A protection cavity 112 corresponding to the thermal conducting medium 210 is recessed on one of the two opposite plate surfaces 111 of the plate body 110, and a plurality of columnar support members 113 are formed on the other plate surface 111. When the plate body 110 covers the bottom of the heat sink 200, the thermal conducting medium 210 may be just accommodated in the protection cavity 112. Or, the bottom of the heat sink 200 rest on the top ends of the support members 113, so that the thermal conducting medium 210 is separated from the plate surface 111 by a distance without contacting the plate surface 111.

[0042]As shown in FIGS. 3A to 3G, a plurality of recess holes 115 corresponding to the support members 113 formed on one plate surface 111 is formed on the plate surface 111 at the other side. Furthermore, an L-shaped recess portion 114 corresponding to the size of the heat sink 200 is respectively formed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com