High fiber extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

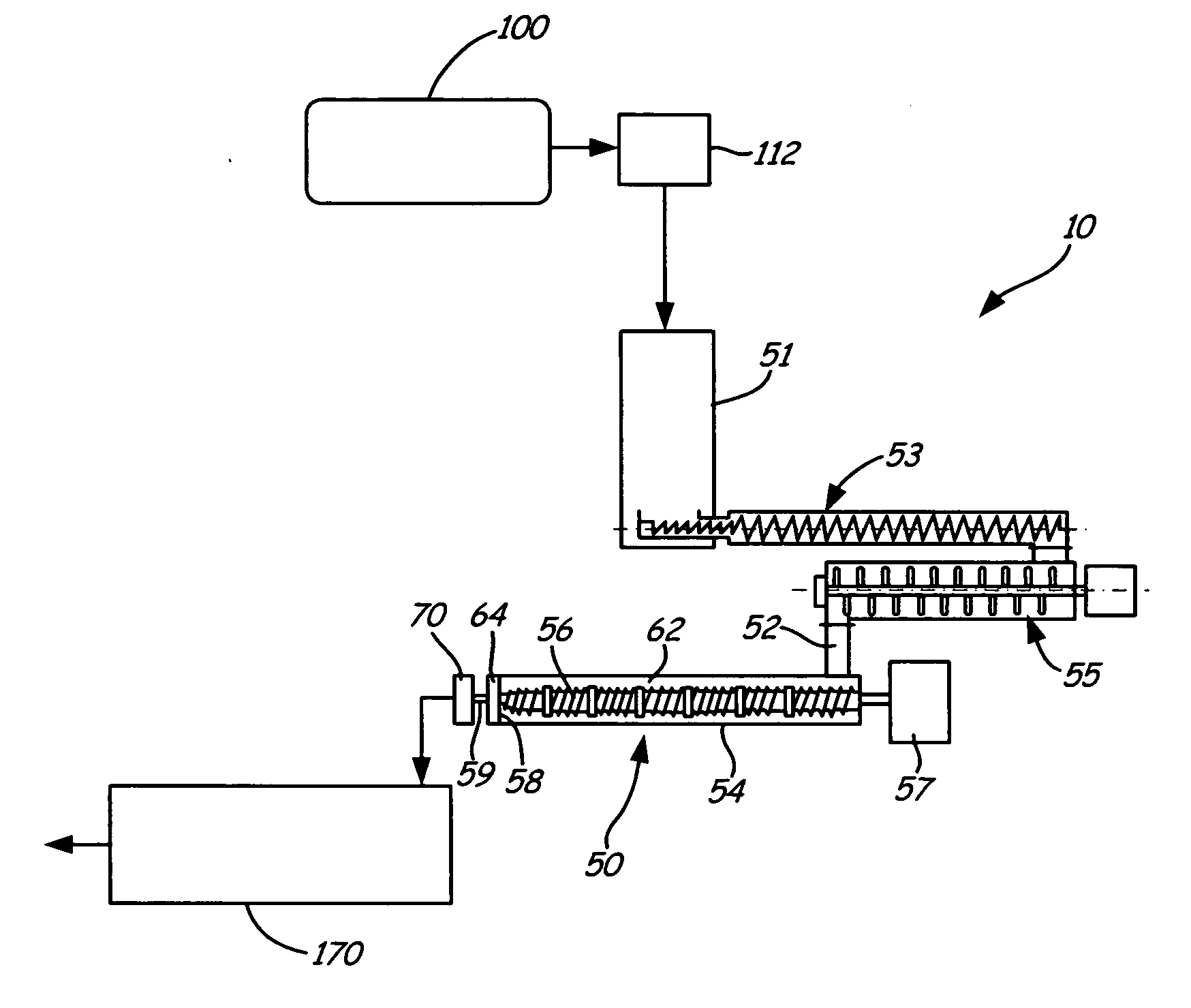

Image

Examples

example 1

[0036]This example illustrates the use of a gum as a binder during extrusion of an animal feed having less than 4 weight percent starch. 5ZF1 Mazuri Wild Herbivore Diet Hi-Fiber meal (PMI Nutritional International, LLC of Brentwood, Mo.) having less than 4 weight percent starch was homogeneously mixed with approximately 5%, 3% and then 1% of a heat-settable gum in the form of Ticagel PF-80 (TIC gums, Inc. of Belcamp, Md.). 5ZF1 Mazuri Wild Herbivore Hi-Fiber has the following ingredients:

IngredientPartsGround Soy Hulls50.71Dehulled Soymeal11.49Ground Aspen10.00Ground Beet Pulp10.00Ground Oat Hulls5.00Molasses5.00Soybean Oil1.76Ground Flax Seed1.00Brewers Yeast1.00Calcium Propionate0.50Apple Flavor0.30Sucrose0.10Vitamins, Minerals and3.14Supplements

In the three runs, Ticagel PF-80 a pet food-grade kappa-carrageenan that forms a gel, was used. The dry mixture was homogeneously mixed and then ground in a Fitzmill® Grinder (The Fitzpatrick Company of Elmhurst, Ill.) through a 4 / 64 inch ...

example 2

[0040]5ZF1 Mazuri Wild Herbivore Diet Hi-Fiber meal (PMI International, LLC of Brentwood, Mo.) was mixed with approximately 10% of Ticagel 550 PT in a first run and 10% Guar 8 / 24 in a second run. (Both from TIC gums, Inc. of Belcamp, Md.). 5ZF1 contains less than 4 weight percent starch Both mixtures were homogeneously mixed and then ground in a Fitzmill® Grinder (The Fitzpatrick Company of Elmhurst, Ill.) passing through a 4 / 64 inch screen.

[0041]After grinding, the dry mixture was introduced into the extruder using the extruder setup as described in Example #2.

[0042]The ground dry mixture was mixed with water added at a rate of 0.43 lbs per minute at the conditioning section of the extruder. The addition of steam to the dry mixture formed a mash that had a temperature of about 208° F.

[0043]Additional water was added to the inlet of the barrel at the rate of 1.07 lbs / min. The screw was operated at a speed of about 515 RPM. The hot mash was cooked and sheared until the hot mash forme...

example 3

[0045]Different levels of a kappa-carrageenan gum (Ticagel PF-80) were tested as a binder with 5MG7 Wild Herbivore Diet (from PMI International, LLC of Brentwood, Mo.). 5MG7 Wild Herbivore Diet has the following ingredients:

Ingredient%Ground Soy Hulls43.50Dehulled Soymeal12.89Ground Aspen10.00Ground Beet Pulp10.00Ground Oat Hulls5.00Ticagel PF805.00Molasses5.00Soybean Oil1.78Ground Flax Seed1.00Brewers Yeast1.00Calcium Propionate0.50Orange Flavor0.40Apple Flavor0.30Sucrose0.10Vitamins, Minerals and3.53Supplements

The 5MG7 Wild Herbivore Diet was extruded (Wenger X-200, Wenger Manufacturing Co, Sabetha, Kan.) without a binder and produced particles that would not hold together.

[0046]

TABLE 23% Gum1% Gum1% GumGrind5MG7Meal notnot Ground( 6 / 64 Screen)HerbivoreNo BinderGround 7 / 32″ Die 7 / 32″ DieParticleNoNotNo acceptableAcceptableDurabilityParticleAcceptableParticlesParticlesParticlesMade

[0047]Mixtures for all runs were homogeneously mixed according to the weight percent set forth in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com