Railcar for passenger transport

a passenger transport and railcar technology, applied in the direction of carriages, wagons/vans, locomotives, etc., can solve the problems of consequently the energy consumption of the railcar, reducing the passenger capacity of the architecture, and a large number of bogies also requiring numerous maintenance operations, so as to achieve the effect of reducing maintenance operations, increasing the energy consumption of the vehicle, and increasing the resistance to forward movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

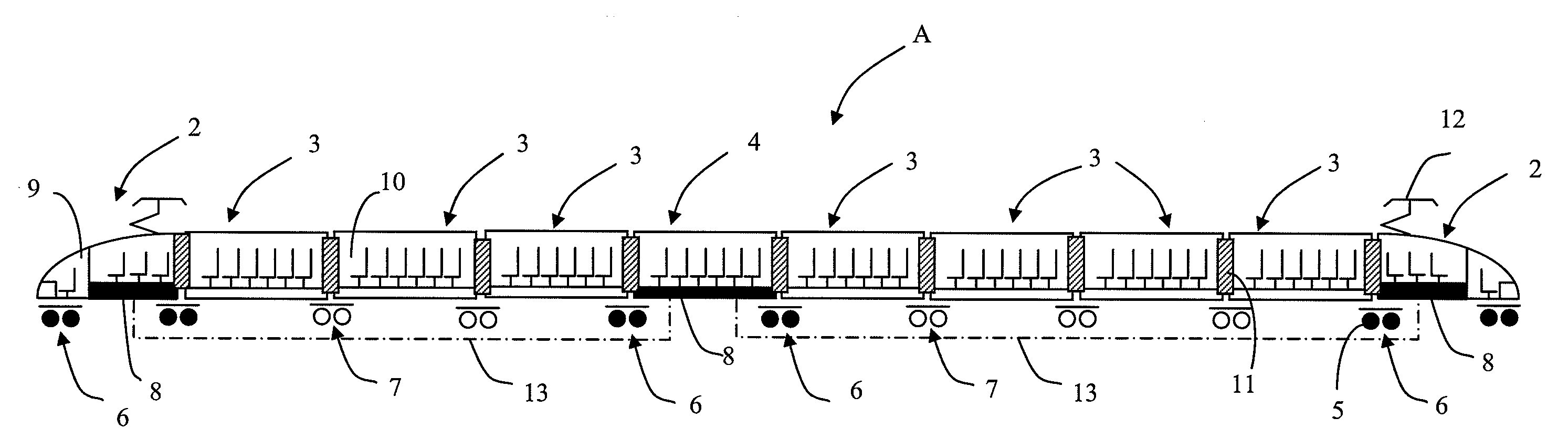

[0050]As illustrated in FIG. 1, a railcar A comprises seven trailers 3 and a motorised intermediate carriage 4 which are arranged between two driving carriages 2.

[0051]A first driving carriage 2 is located at a first end of the railcar A (from the left-hand side in FIG. 1). It has a free end, where a driver's cabin 9 is located, and rests on a motor bogie 6 which is composed of two motor axles 5. A first traction drive 8 is arranged below the passenger compartment 10 of this first driving carriage 2. At the opposite end thereof, the driving carriage 2 is articulated to a first trailer 3. The two ends facing the carriages 2 and 3 rest on a single motor bogie 6 which is composed of two motor axles 5.

[0052]The first trailer 3 therefore shares, at the first end thereof, a motor bogie 6 with the driving carriage 2 and shares, at the other end thereof, a carrier bogie 7 with the second adjacent trailer 3.

[0053]The second trailer 3 is articulated to the first trailer 3 and to the third tra...

second embodiment

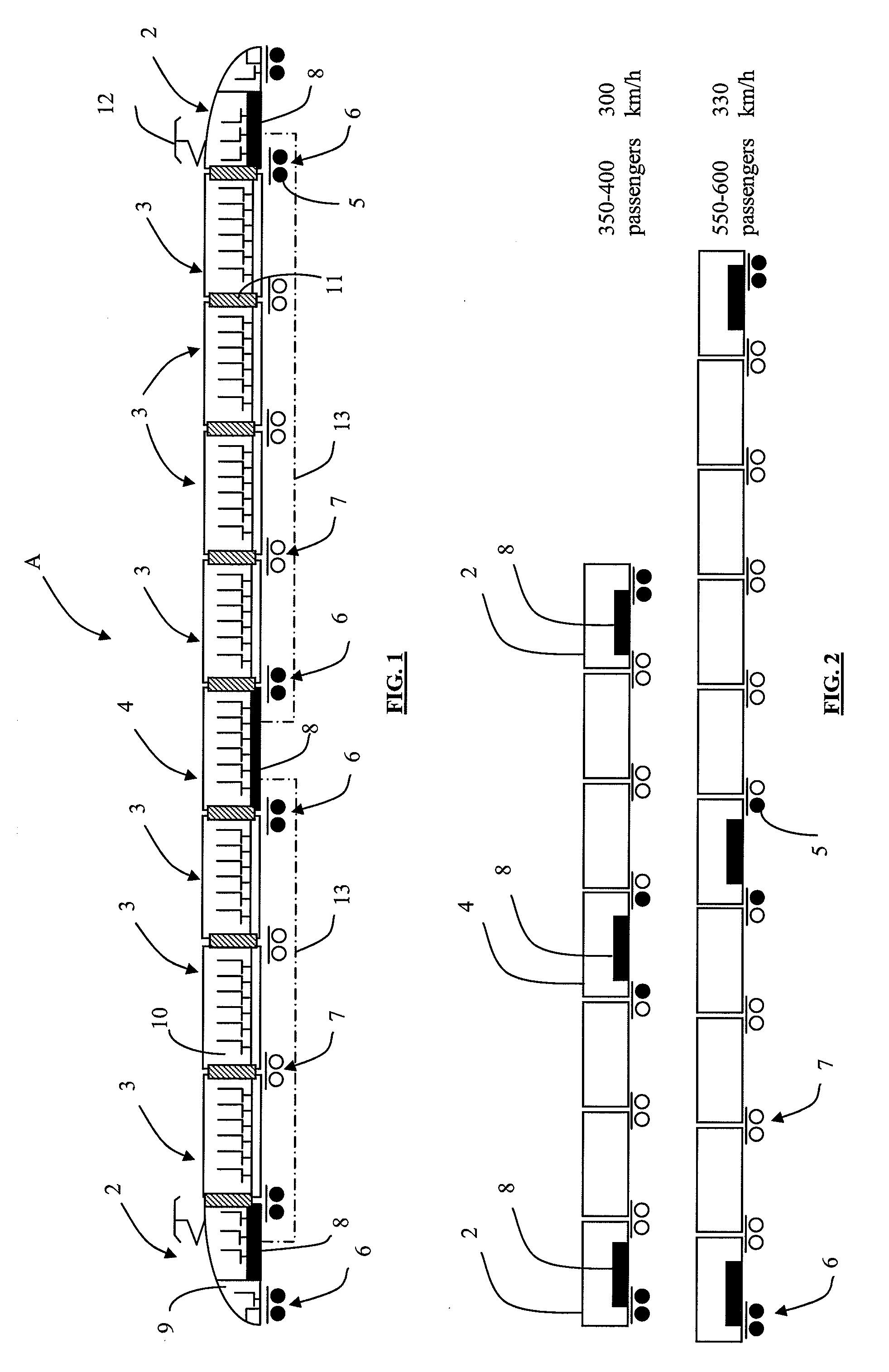

[0068]As illustrated in FIG. 1, the railcar A comprises only single deck carriages. In a variant, the driving carriages 2 and the intermediate carriages 3, 4 are double deck, as illustrated in FIG. 3.

[0069]Advantageously, in a railcar B which has double deck carriages, the lower level of a driving carriage 2 and the motorised intermediate carriage 4 which receives a traction drive 8 is used to accommodate the traction drive(s) 8, the other level being reserved for passengers.

[0070]The passages 11 are placed at the upper level in order to move from one trailer 3 to another. In contrast, the passages between the driving carriages 2 and the adjacent trailers 3 are formed at the lower level. A stairway (not illustrated) which is arranged in the driving carriage 2 and in the trailers 3 allows the upper level to be reached from the access doors (not illustrated) of the carriages 2, 3, 4.

third embodiment

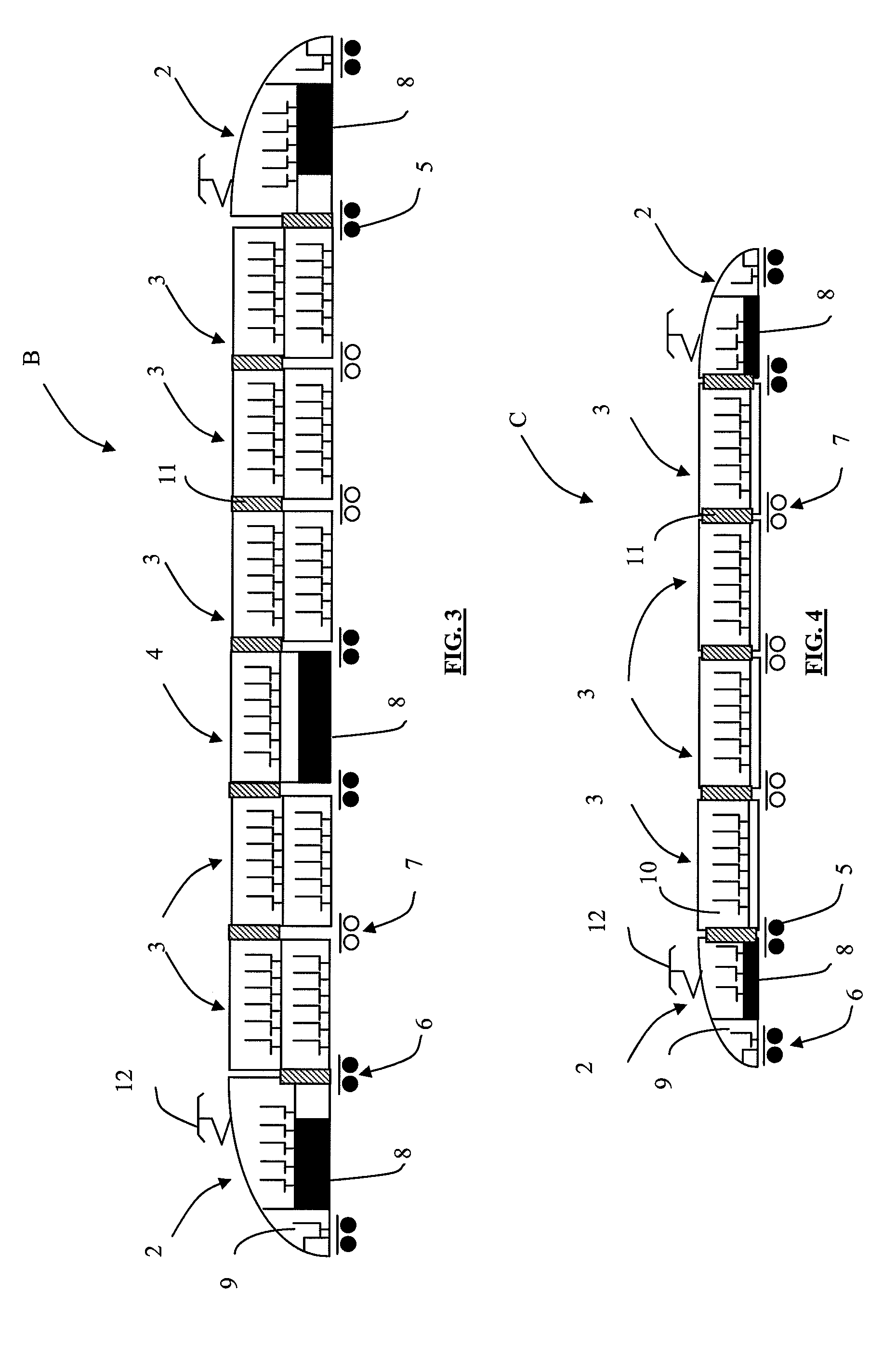

[0071]For a short railcar, in the order of from 120 to 160 m, it is advantageous to reduce the number of motor bogies by removing the motorised intermediate carriage 4 which receives the traction drive(s) 8 and removing the associated motor bogies 6.

[0072]In this manner, in the variant illustrated in FIG. 4, in which the references to the elements which are similar to those of FIG. 1 have been retained, a railcar C is distinguished from that of the preceding embodiments in that it comprises only trailers 3 which have no traction drives 8. The railcar C therefore has no motorised intermediate carriage 4 which receives a traction drive 8.

[0073]The railcar C comprises four motorised bogies 6 which are arranged below the free ends of the driving carriages 2, and in a straddling manner below the end of a driving carriage 2 and the end of the adjacent trailer 3. In accordance with the desired power / mass ratio, from four to eight axles could be motorised, each motor bogie 6 having at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com