Electronic toilet tank monitor utilizing a bistable latching solenoid control circuit

a control circuit and toilet tank technology, applied in water installations, flushing devices, constructions, etc., can solve the problems of increasing overall power consumption, inability to provide constant power source to existing toilets, and inability to include power source in bathroom facilities presently, so as to achieve low power consumption, reliable control of water level in toilet tanks, and faster acting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

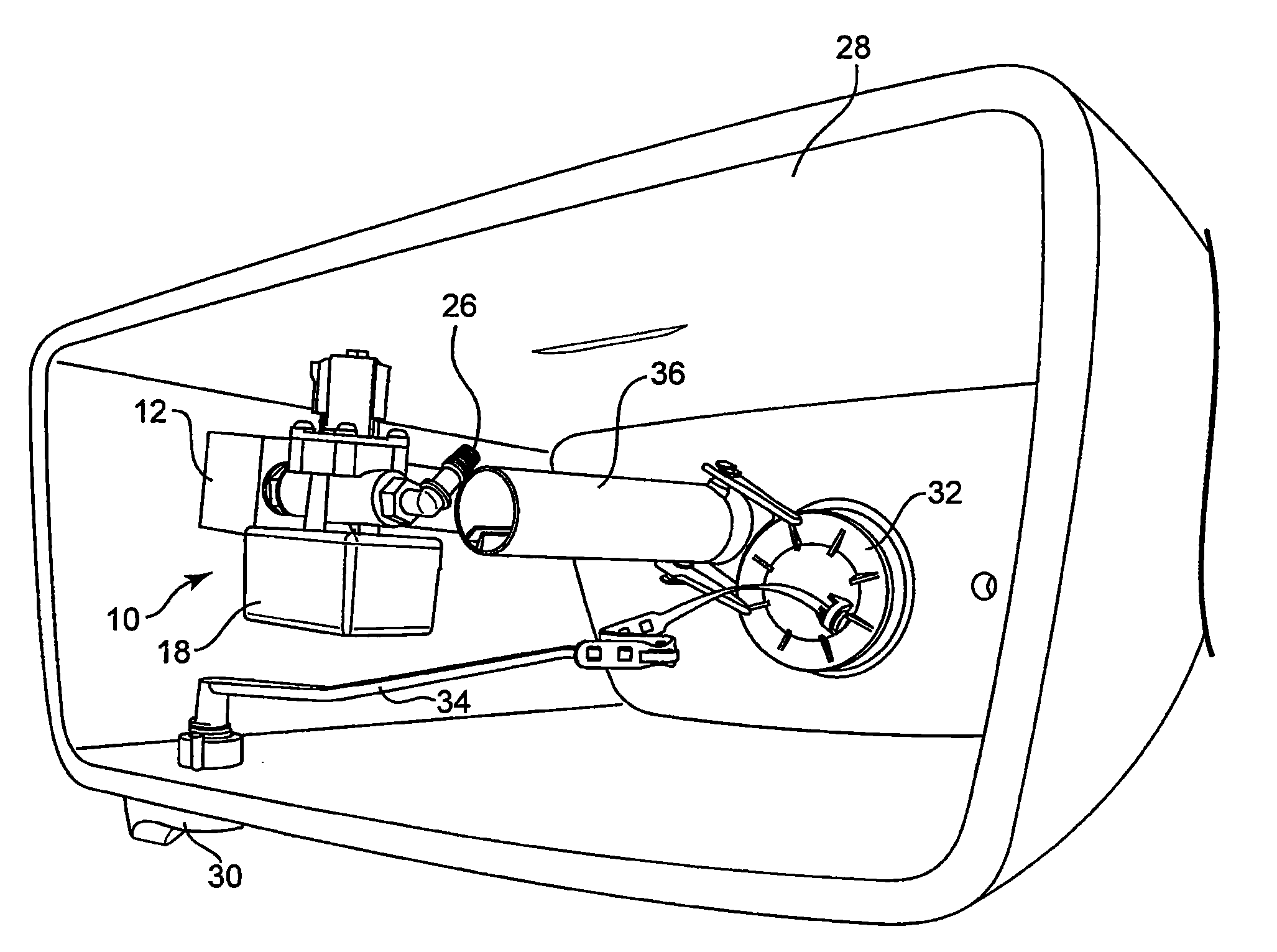

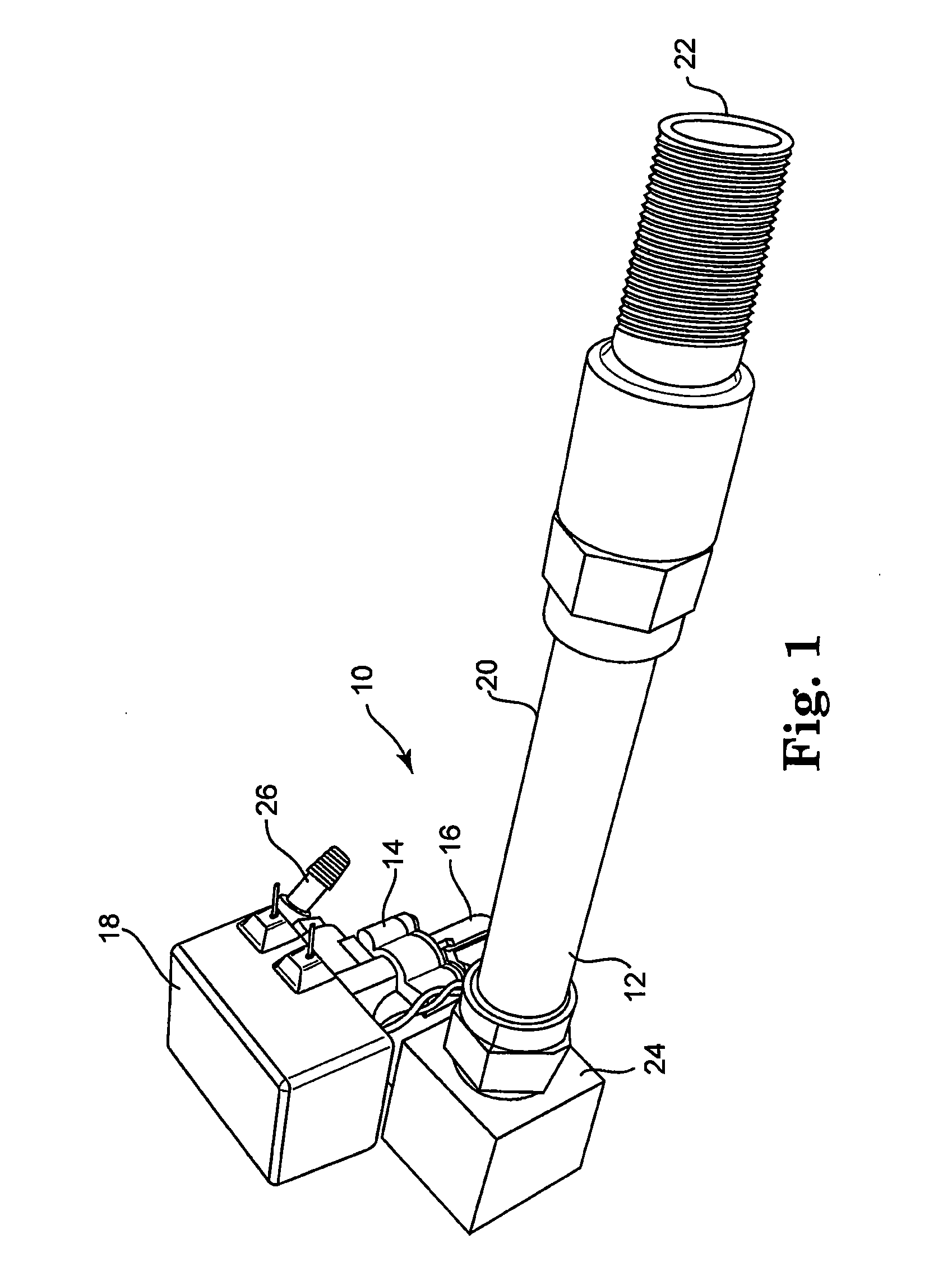

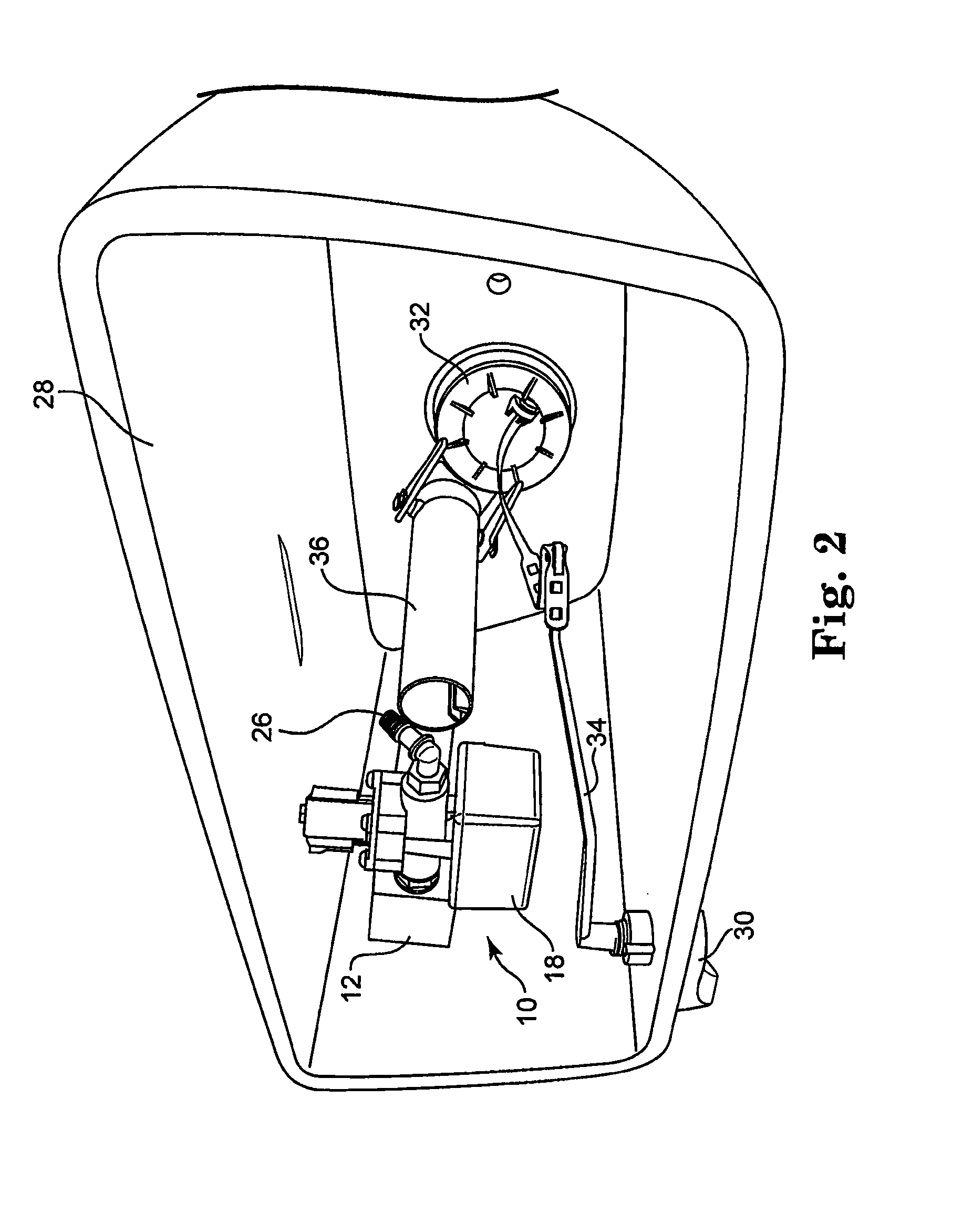

[0027]A toilet tank electronic monitor 10 in accordance with the present invention senses the presence or absence of water, i.e. the water level, in a toilet tank 28 (FIG. 2) using detection pins. This detection methodology is thus used to control at least one flow valve via a control circuit. Referring to FIG. 1, the toilet tank electronic monitor 10 in accordance with the present invention includes a fill tube assembly 12, a valve 14, a solenoid 16 and a control box 18. Fill tube assembly 12 includes a water conduit 20, a water inlet end 22 and a valve inlet end 24. While water conduit 20 is depicted as a generally tubular shape in the figures, those skilled in the art can appreciate that water conduit 20 can have various shapes and sizes to accommodate water feed to valve 14. A water source is connected to water inlet end 22 such that water is supplied from water inlet end 22 through water conduit 20 into valve inlet end 24. Water is provided to fill nozzle 26 only when valve 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com