Fixing frame for a solar energy module

a solar energy module and fixing frame technology, applied in the direction of heat collector mounting/support, pv power plants, light and heating equipment, etc., can solve the problem of supporting board breaking at welding points, and achieve the effect of high strength, high force resistance, and efficient resistance to external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]While this invention is capable of embodiment in many different forms, shown in the drawings and herein described in detail is the preferred embodiment of the invention. The preferred embodiment is disclosed with the understanding that the present description is but one example of the principles of the invention and is not intended to limit the broad aspects of the invention to the single embodiment illustrated.

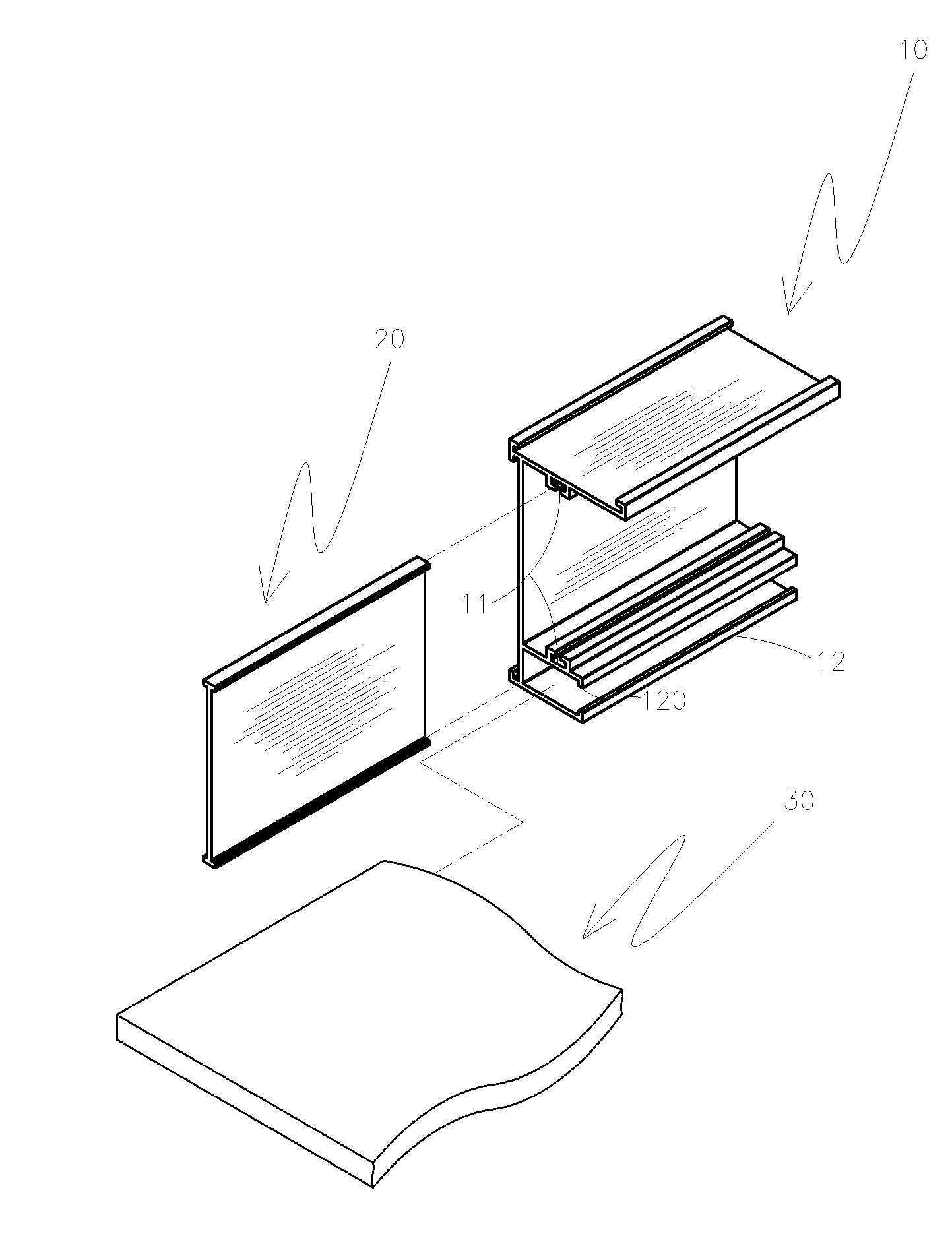

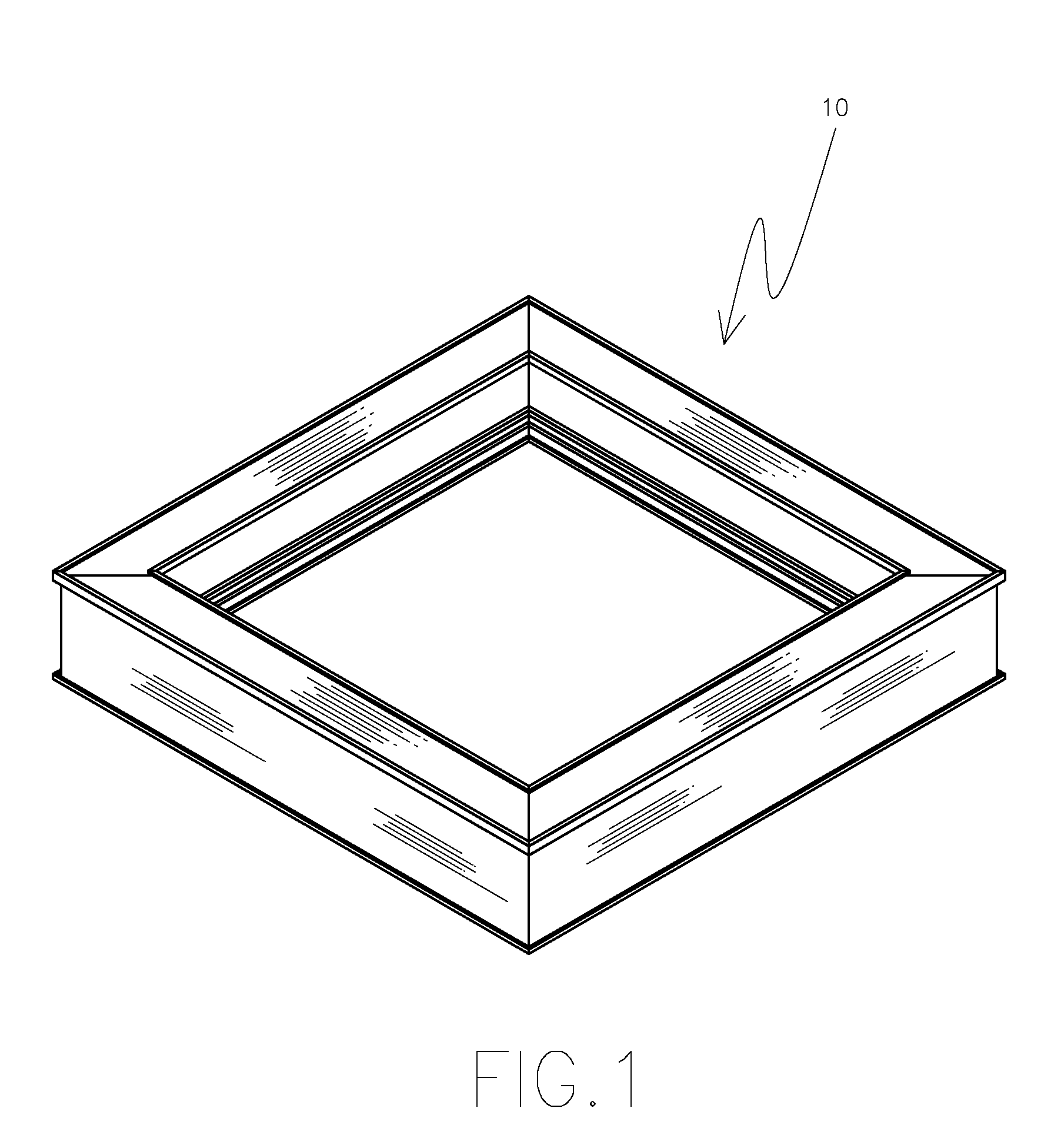

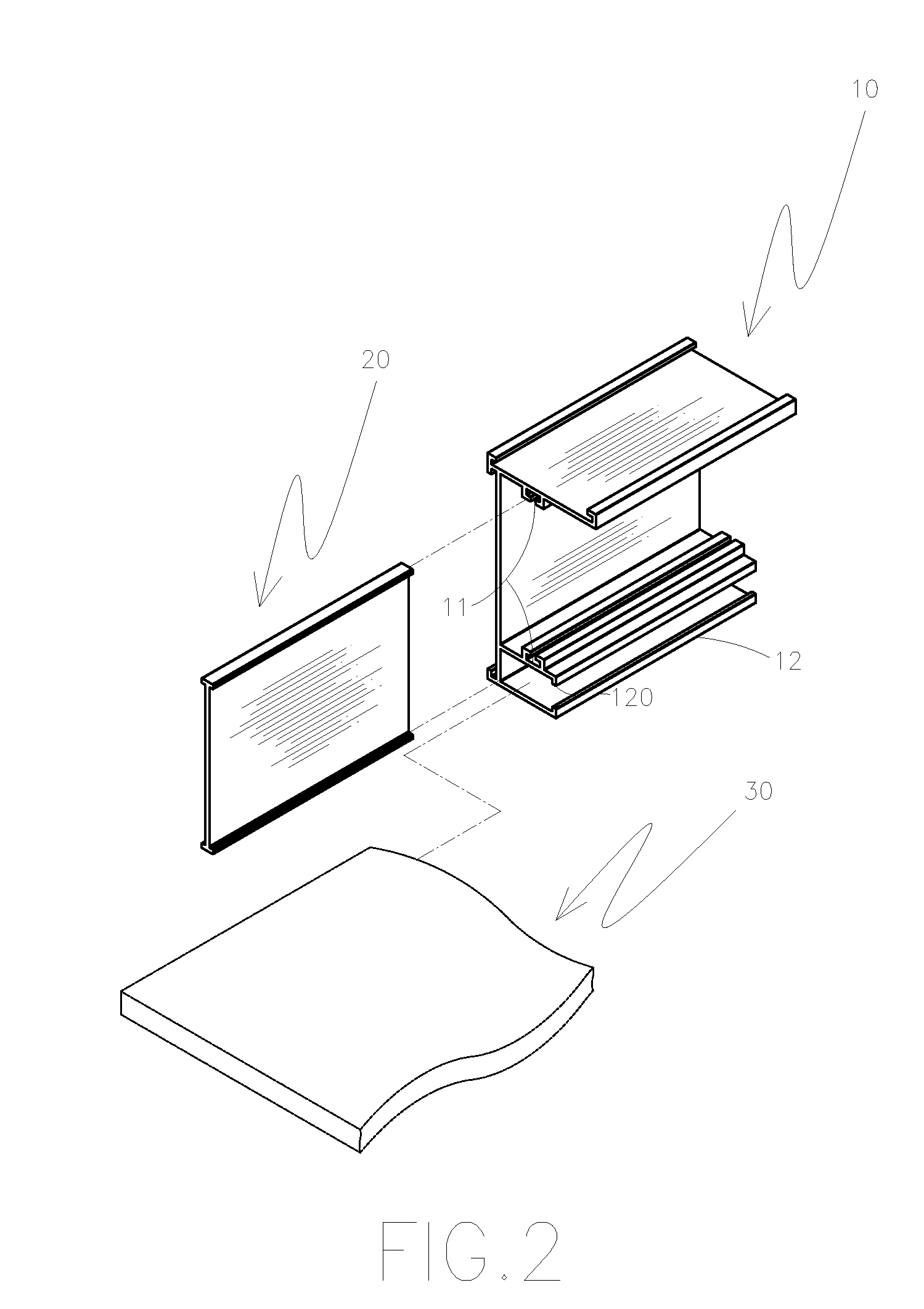

[0017]FIGS. 1 to 3 are perspective, segmented perspective and sectional views schematically showing a fixing frame for a solar energy module of the present invention.

[0018]The frame comprises:

[0019]a frame body 10 having inserting grooves 11 and a locking chute 12, wherein the locking chute 12 contains the locking flanges 120;

[0020]an I-shaped supporting board 20 that is installed by sliding into the inserting grooves 11 of the frame body 10; and

[0021]the frame body 10 and the I-shaped supporting board 20 are made of a high-strength aluminum alloy (aluminum alloy design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com