Method and system for rub detection in a steam turbine

a technology for steam turbines and rub detection, which is applied in the direction of instruments, heat measurement, engine starters, etc., can solve the problems of reducing the efficiency of the turbine, causing the turbine blades to rub against the stationary casing, and damage to the turbine components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

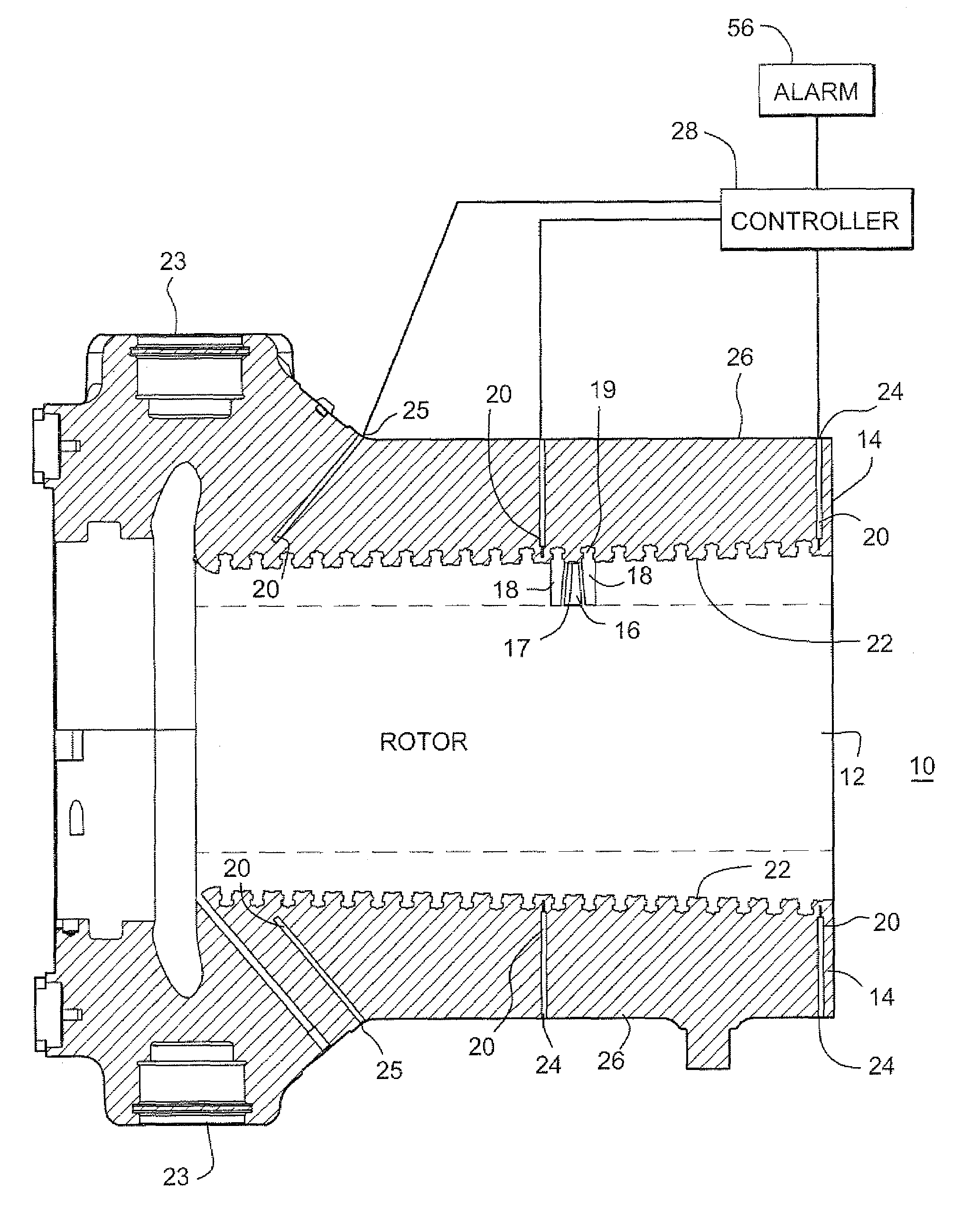

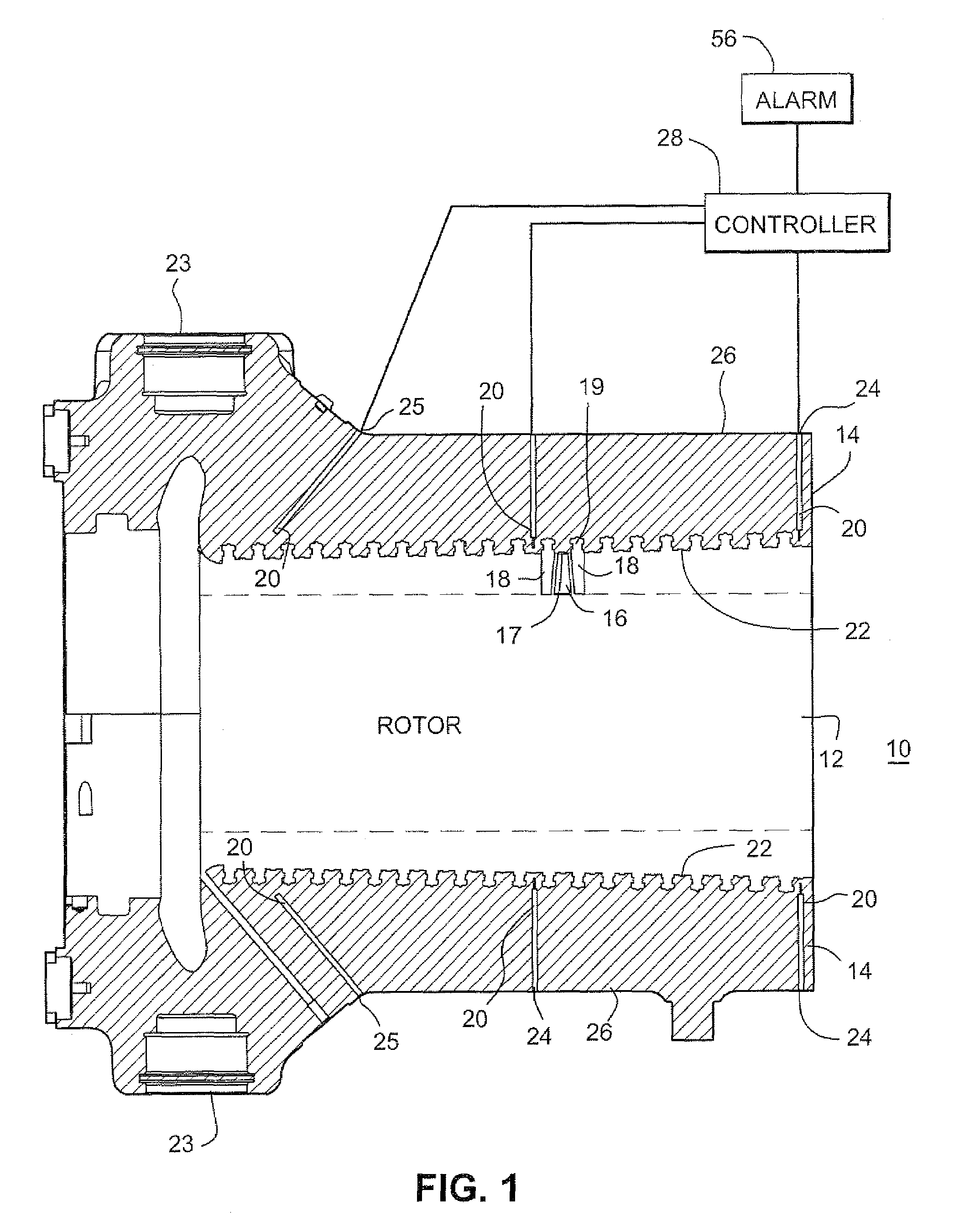

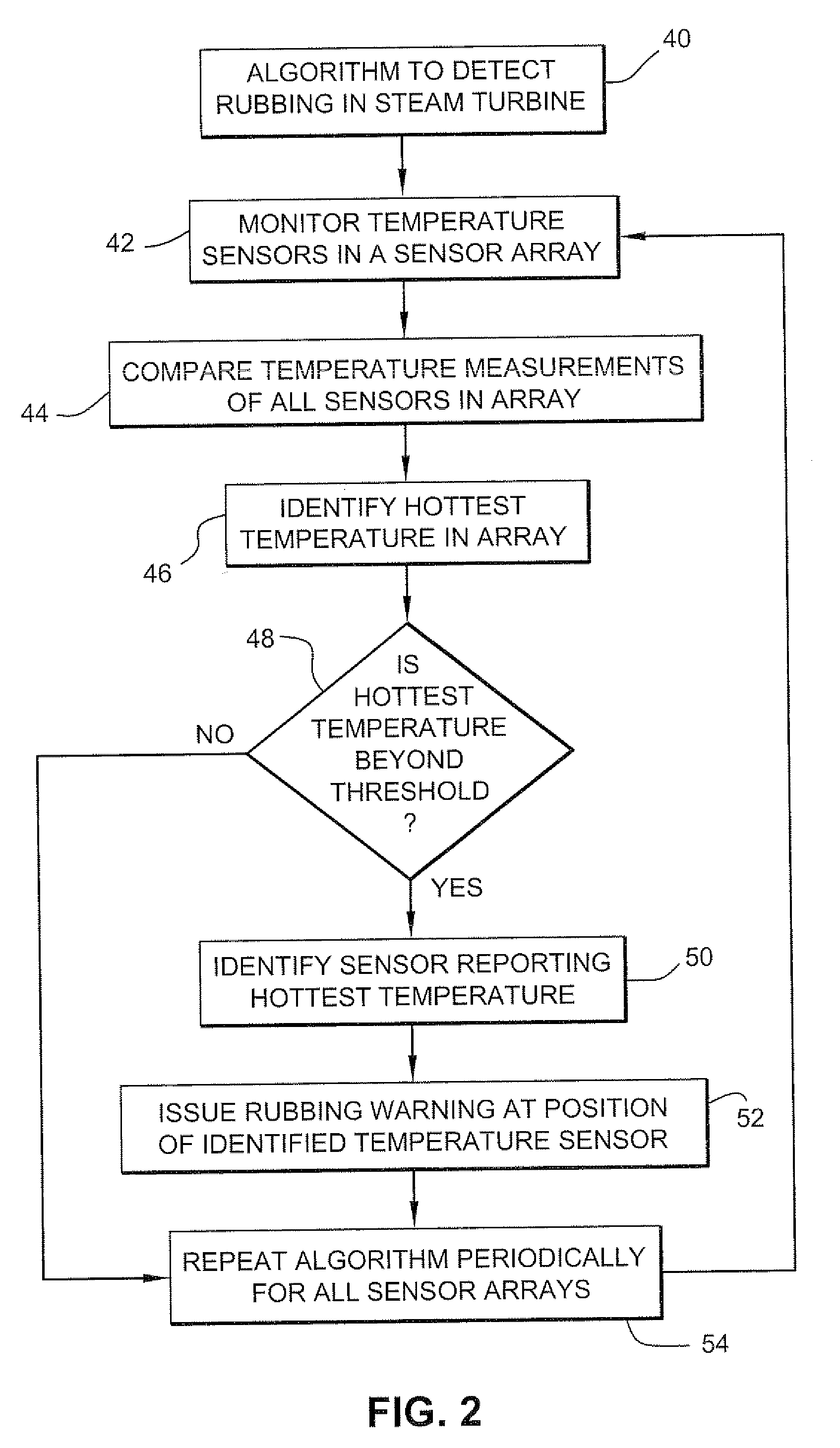

[0010]A novel system and method has been developed to detect rubbing in a steam turbine using temperature sensors on the turbine casing. The friction of rubbing creates heat at the rubbing location. The heating is localized in the metallic casing. Temperature sensors, e.g., thermocouples, embedded in the casing report the temperature increase in the casing due to the rubbing. The sensor reporting a high temperature is determined by comparing the temperature signal reports from an array of thermocouples. A rub is detected when the temperature report from one sensor in the array is sufficiently above the temperature reports from other sensors in the array. The location of the rub is determined to be proximate to the temperature sensor that reported the high temperature.

[0011]FIG. 1 is a side view showing in cross-section a steam turbine 10 having a rotor 12 and a turbine casing 14. The rotor includes rows of turbine rotor buckets 16 (turbine blades) that are each arranged between rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com