System for controlled fluid heating using air conditioning waste heat

a technology of air conditioning and waste heat, which is applied in the direction of compression machines with several condensers, light and heating apparatus, machine operation mode, etc., can solve the problems of equipment damage, cost of operation, commercial success, etc., and achieve the effect of optimum air conditioning system efficiency and without equipment damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

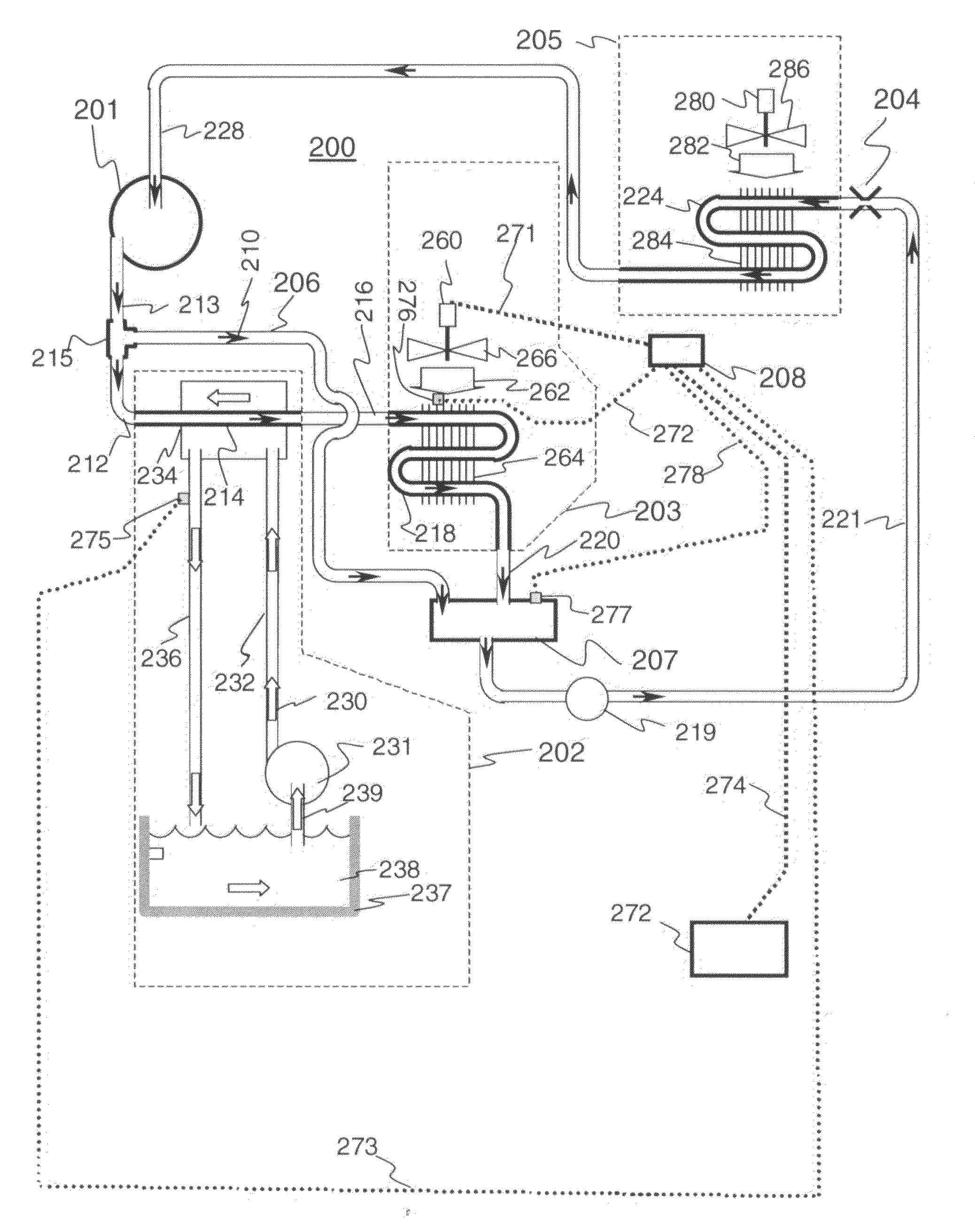

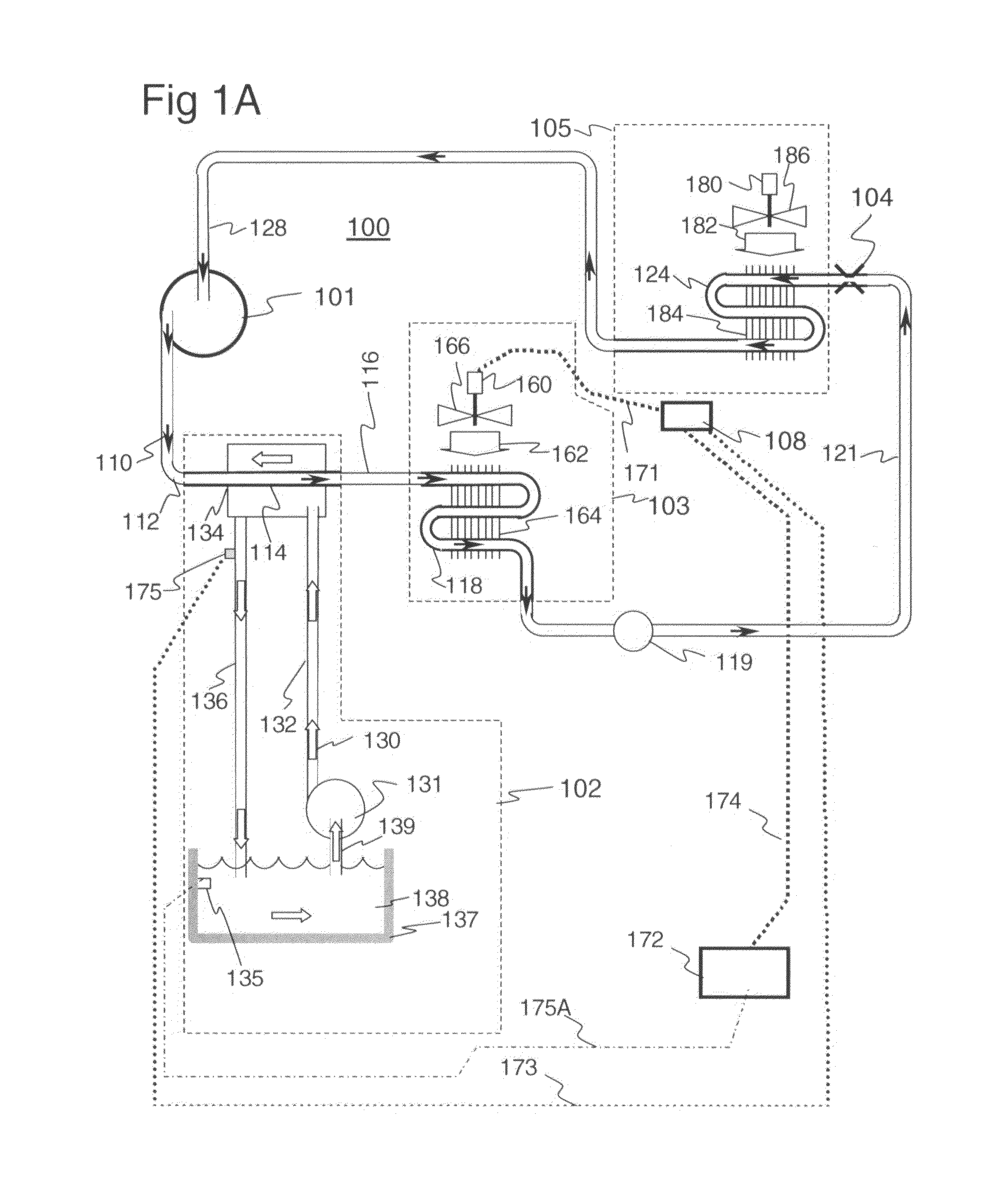

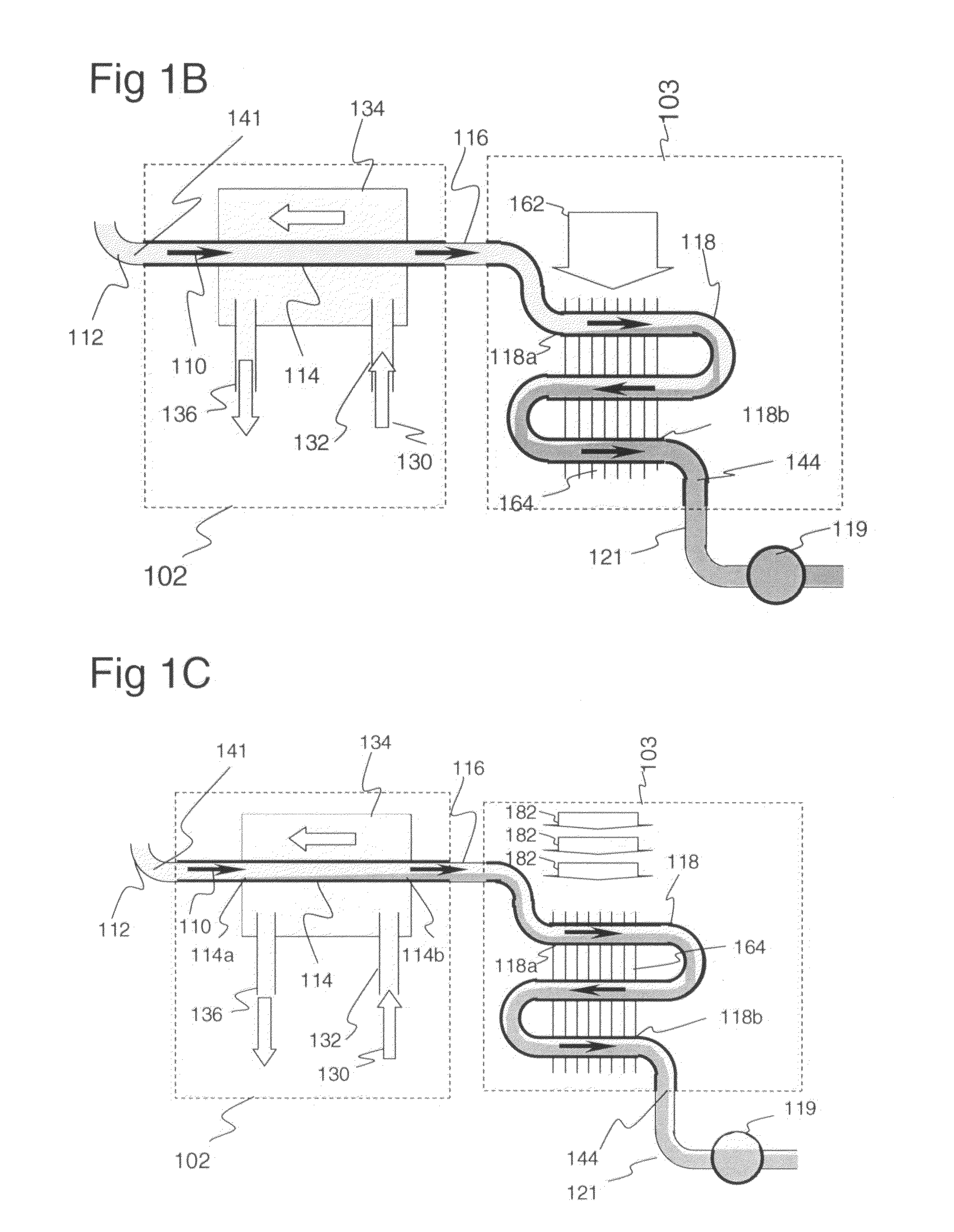

[0014]The use of air conditioning waste heat to heat swimming pool water has been demonstrated and is well know in the art. Davies discloses a system for controlled heating of pool water using waste heat of an air conditioner where the refrigerant-to-air condenser fan is cycled on and off in response to a sensor monitoring the temperature of the water exiting the refrigerant-to-water condenser. If the water temperature is below the Fan Off Set Point, the air conditioning condenser fan will be turned off, increasing the condensing pressure and temperature, increasing the amount of heat going into the refrigerant-to-water condenser, increasing the temperature of the water exiting refrigerant-to-water condenser. When the water temperature reaches the Fan On Set Point, which is higher than the Fan Off Set Point, the air conditioning fan will be turned on, decreasing the condensing pressure and temperature, reducing the amount of heat going into the refrigerant-to-water condenser, loweri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com