Flat heat pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

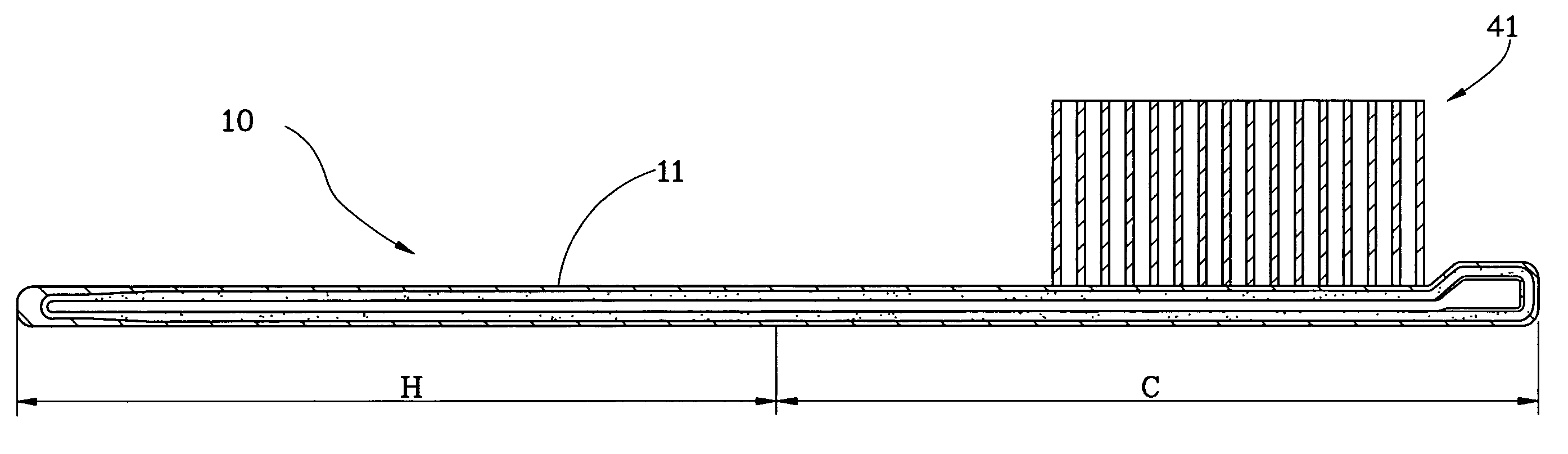

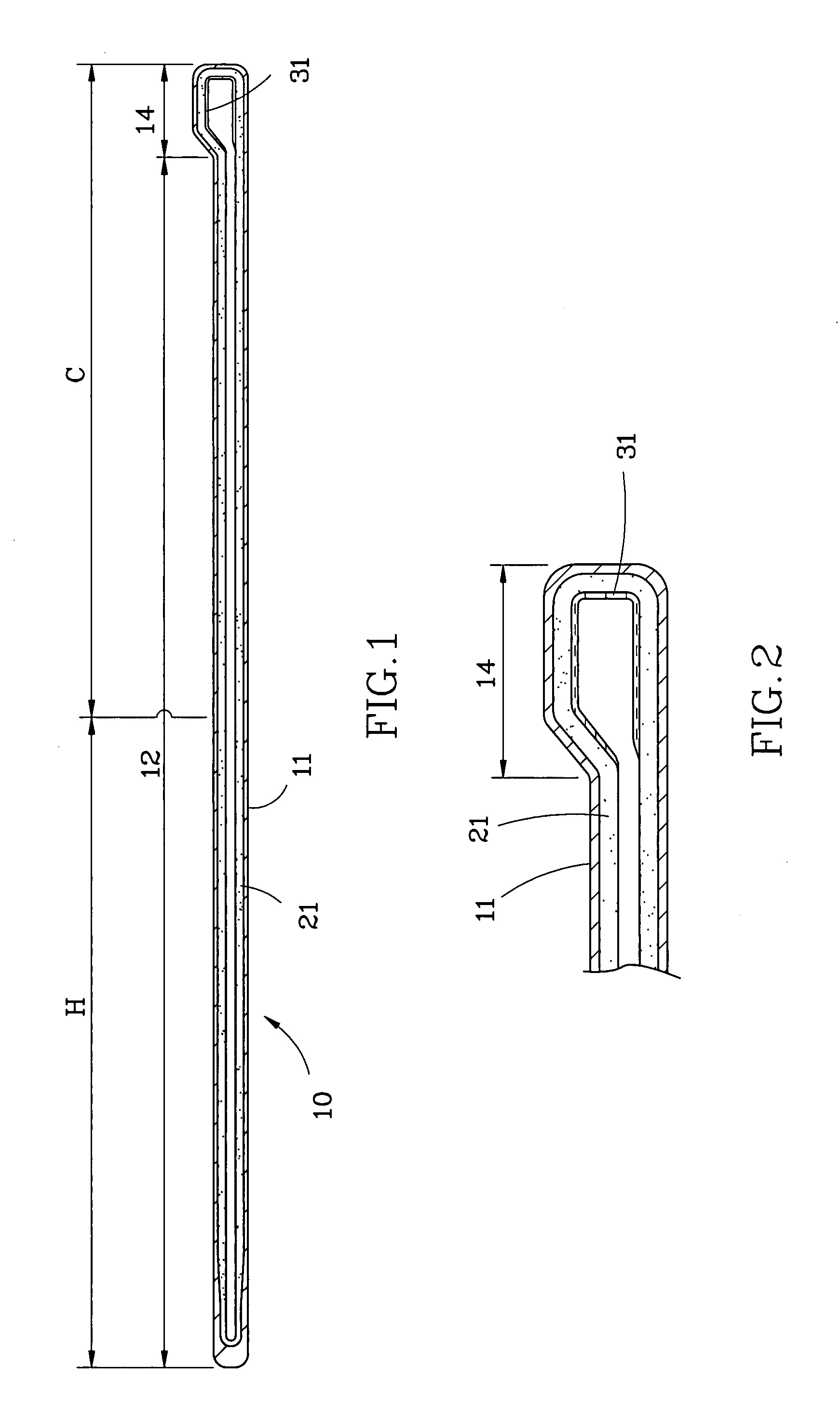

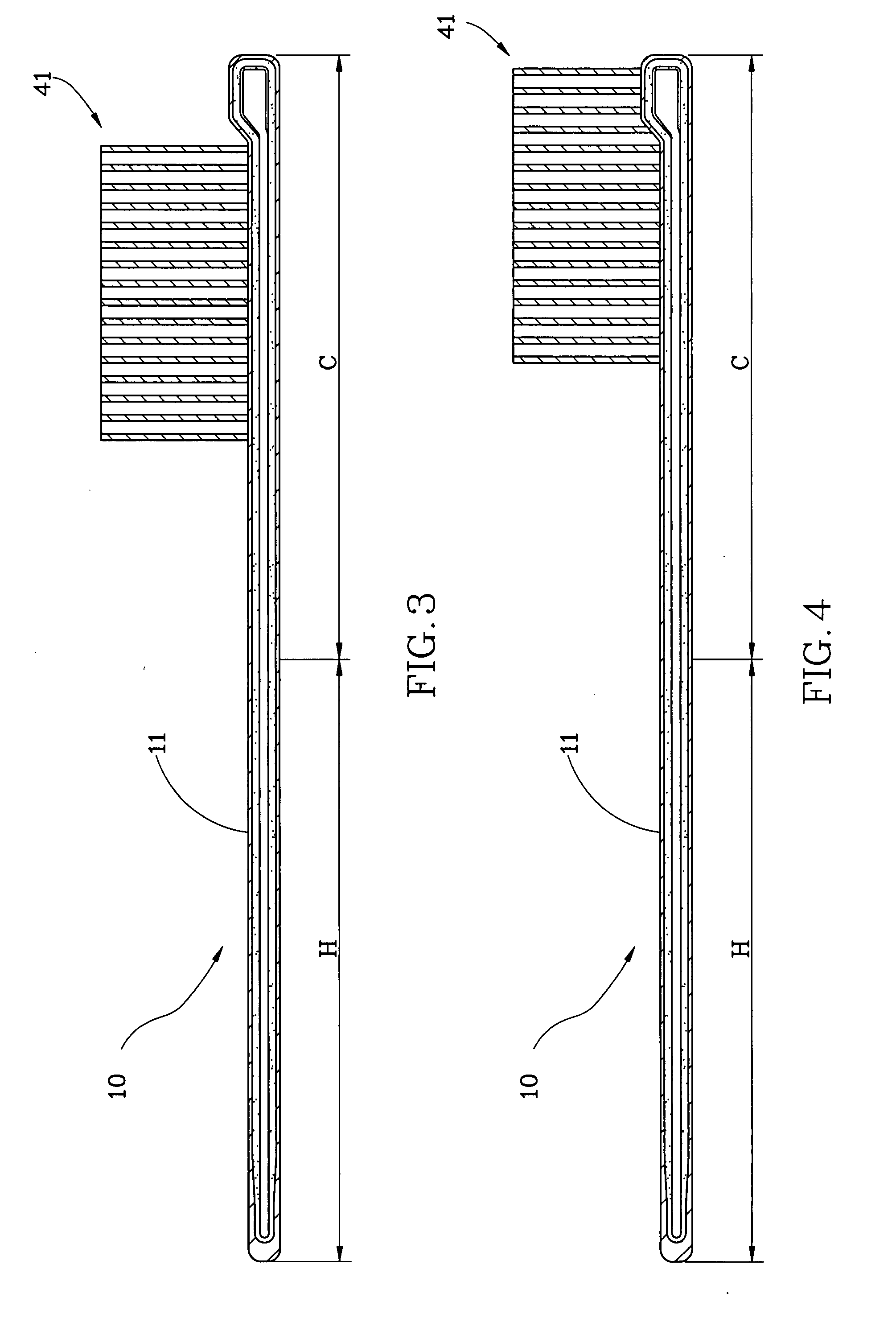

[0016]Referring to FIG. 1 and FIG. 2, the flat heat pipe 10 of present invention including: a tubular member 11, a capillary wick 21 and liquid 31. Wherein:

[0017]Said tubular member 11 makes of copper and both ends are sealed.

[0018]Said capillary wick 21 is disposed at the internal sidewall of said tubular member 11. Said capillary wick 21 can be a metal mesh or copper powder or grooves that is provided at the internal sidewall of said tubular member 11. In this embodiment, present invention takes the sintering by copper powder as an illustration. The metal mesh and the grooves type are all prior art skills and the capillary wick is not the technique key point of present invention, so there are no more redundancy words.

[0019]Said liquid 31 is disposed into said tubular member 11. Wherein said tubular member 11 defines a flat section 12 and a thicker section 14. Said flat section 12 is placed at one end of said tubular member 11 and said thicker section 14 is placed at the other end,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com