Unit and Method for Conveying Workpieces Along a Processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

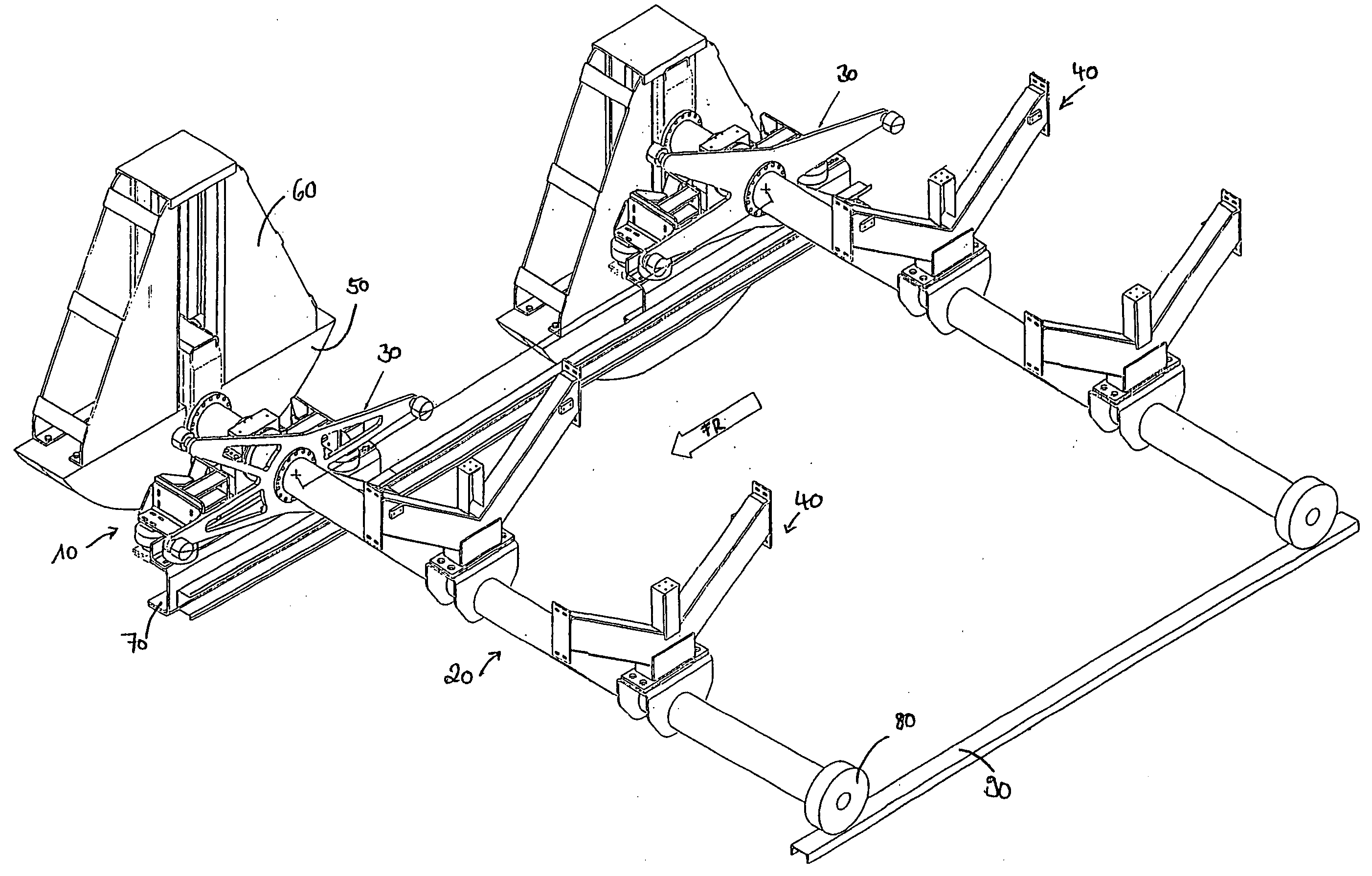

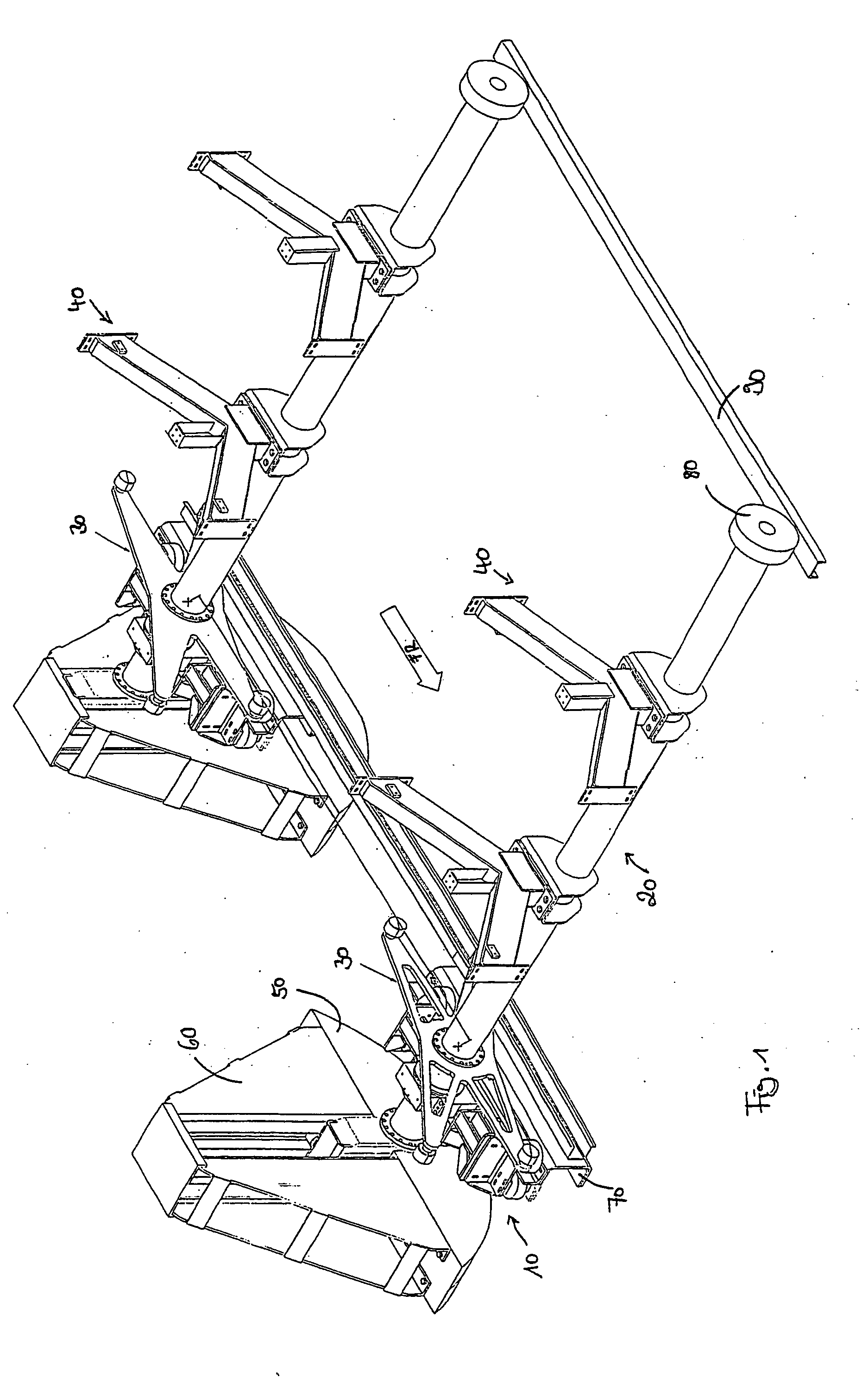

[0041]A schematic overall view of a unit according to the invention is shown in FIG. 1.

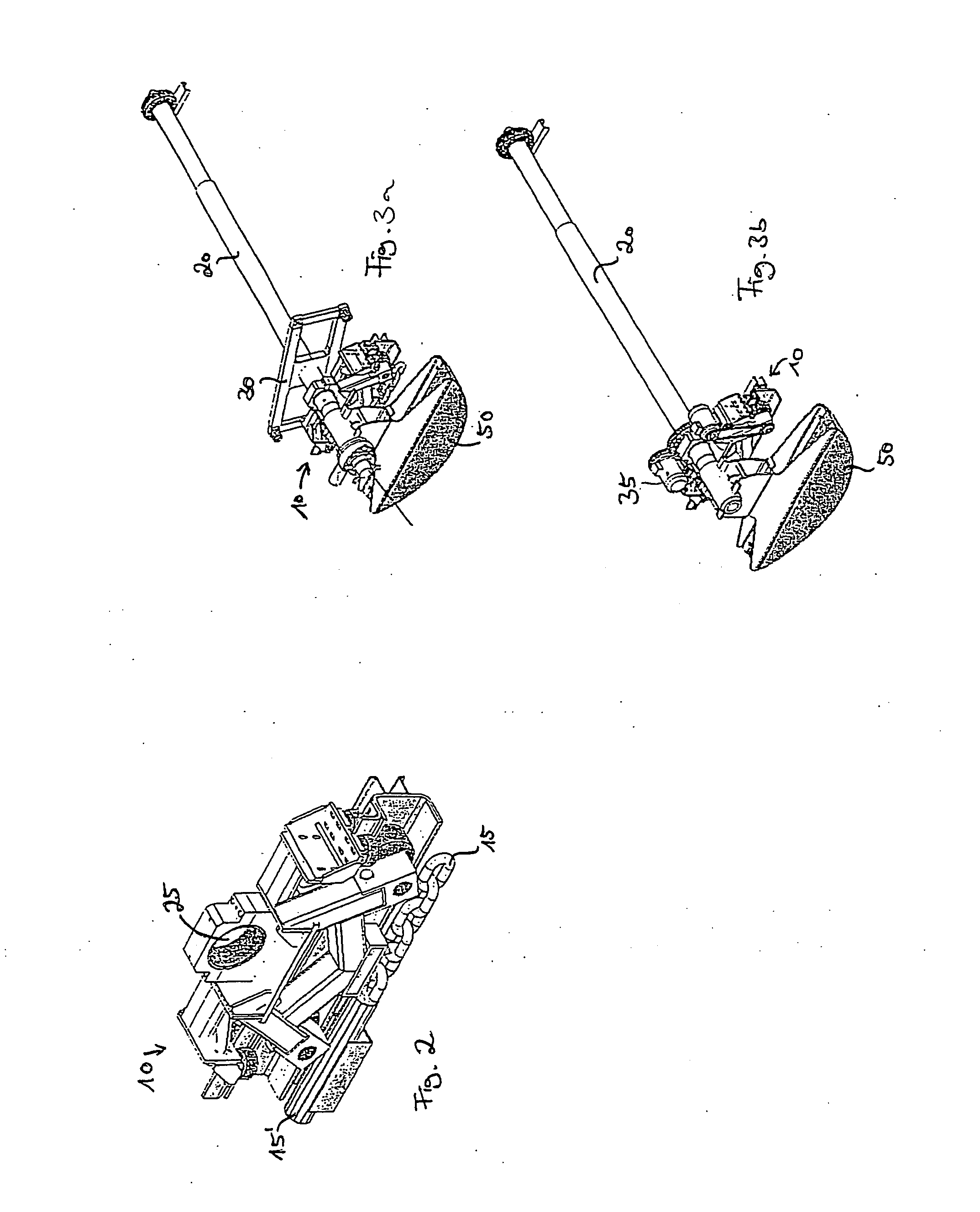

[0042]Using this unit, workpieces can be transported through a processing station. In particular, a unit of this type may serve to guide car body parts through a dipping bath in order to varnish the same. For this purpose, the unit comprises a plurality of tool carriers, two of which are shown in FIG. 1, and which are each formed by a transport car 10 and a rotating shaft 20 as essential parts.

[0043]Rotating shafts 20, in turn, each show mounts 40, on which the car body parts which are to be varnished can be fixed directly or using so-called skids. Rotating shafts 20 are rotatably supported on transport car 10 and move together with transport car 10 in a conveying direction characterized by “FR” along a guiding way 70. For this purpose, transport cars 10 are driven, for example using a conveying chain, a rope or a belt. A dipping bath (not shown), into which the car body parts which are fixed to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com