Gasification reactor

a gasification reactor and gas technology, applied in the direction of gasifier mechanical details, combustible gas purification/modification, combustible gas production, etc., can solve the problems of affecting the operation of the process, affecting the opening of the burner, etc., and achieve the effect of less damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

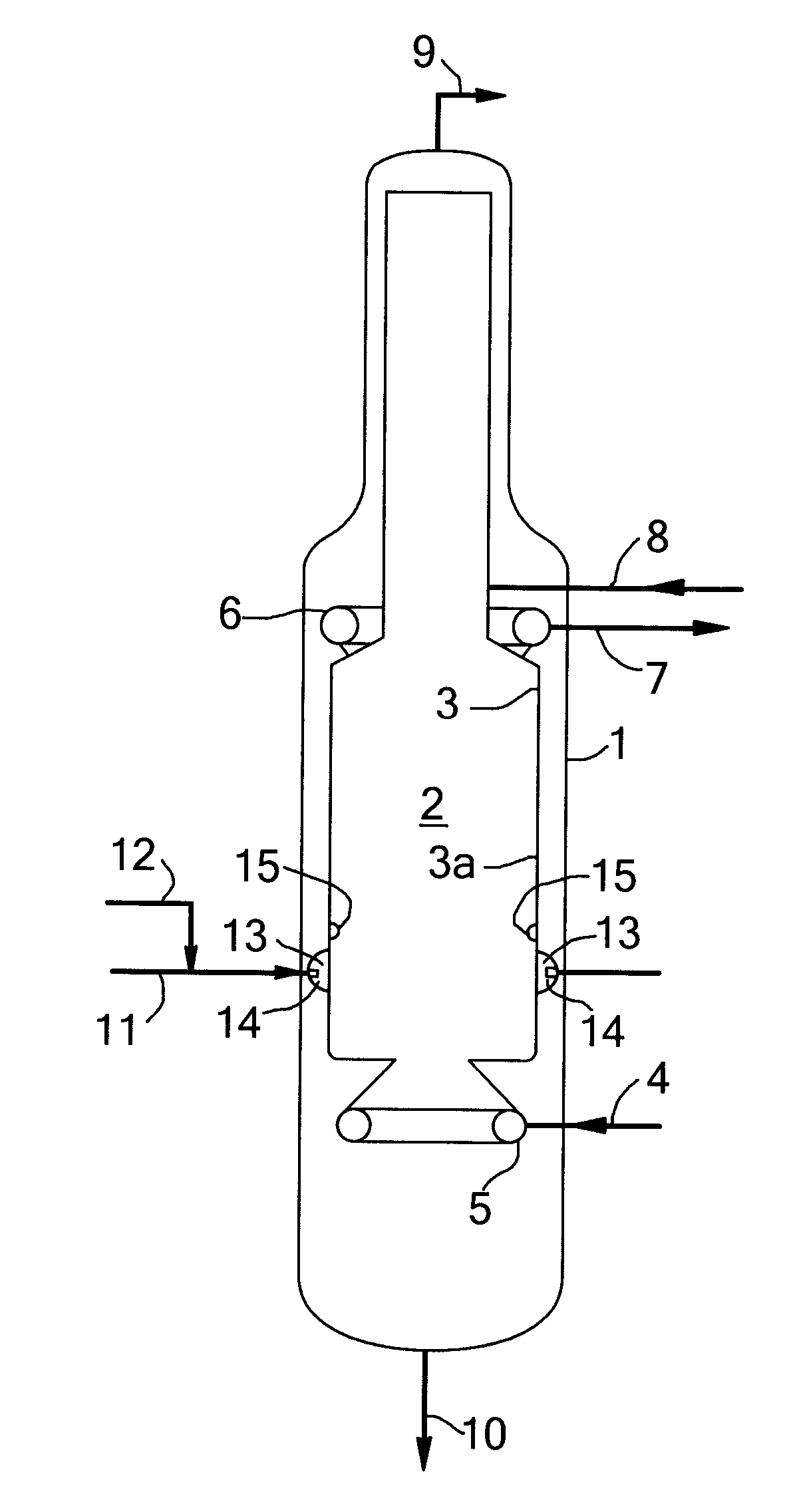

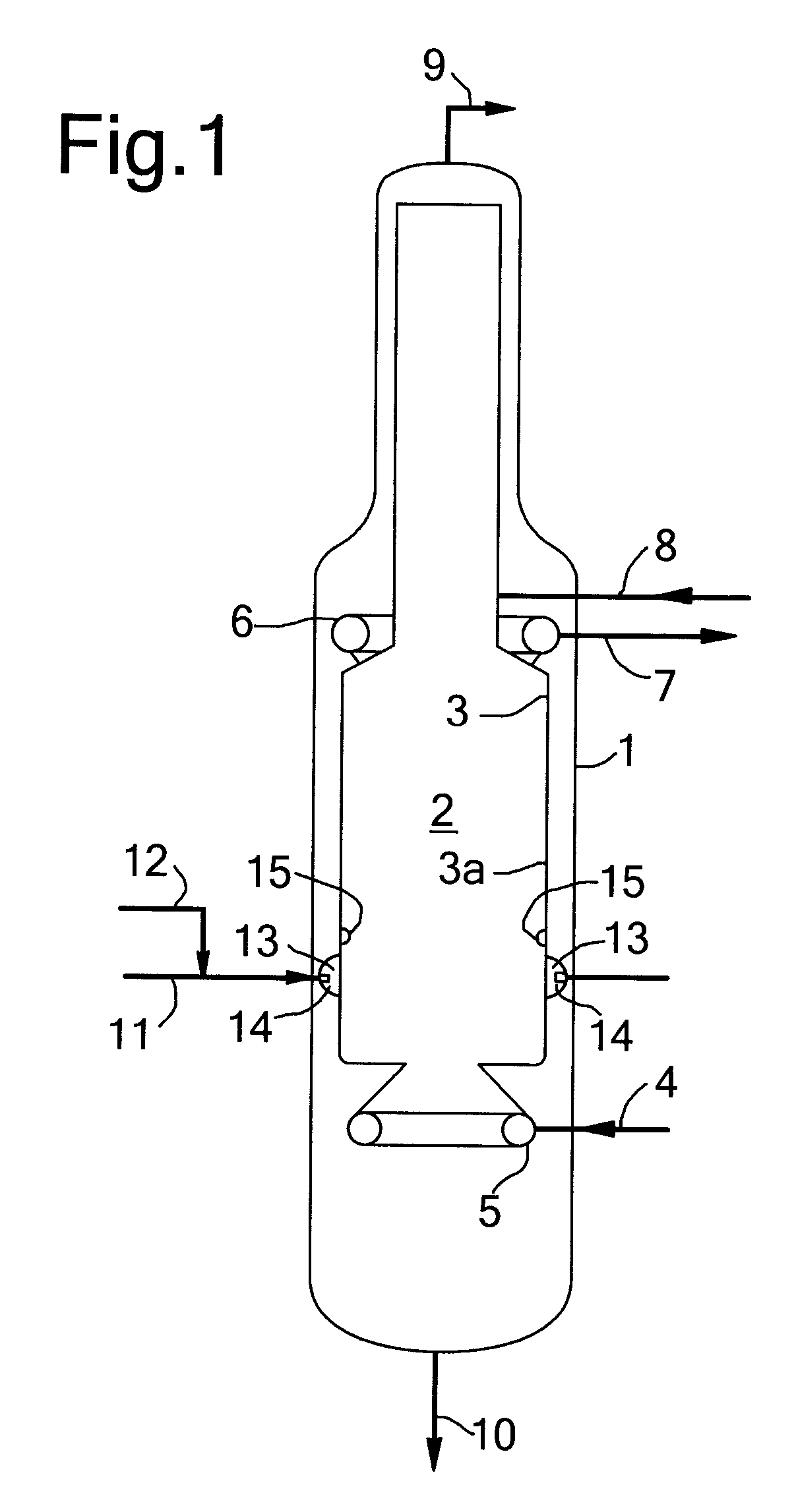

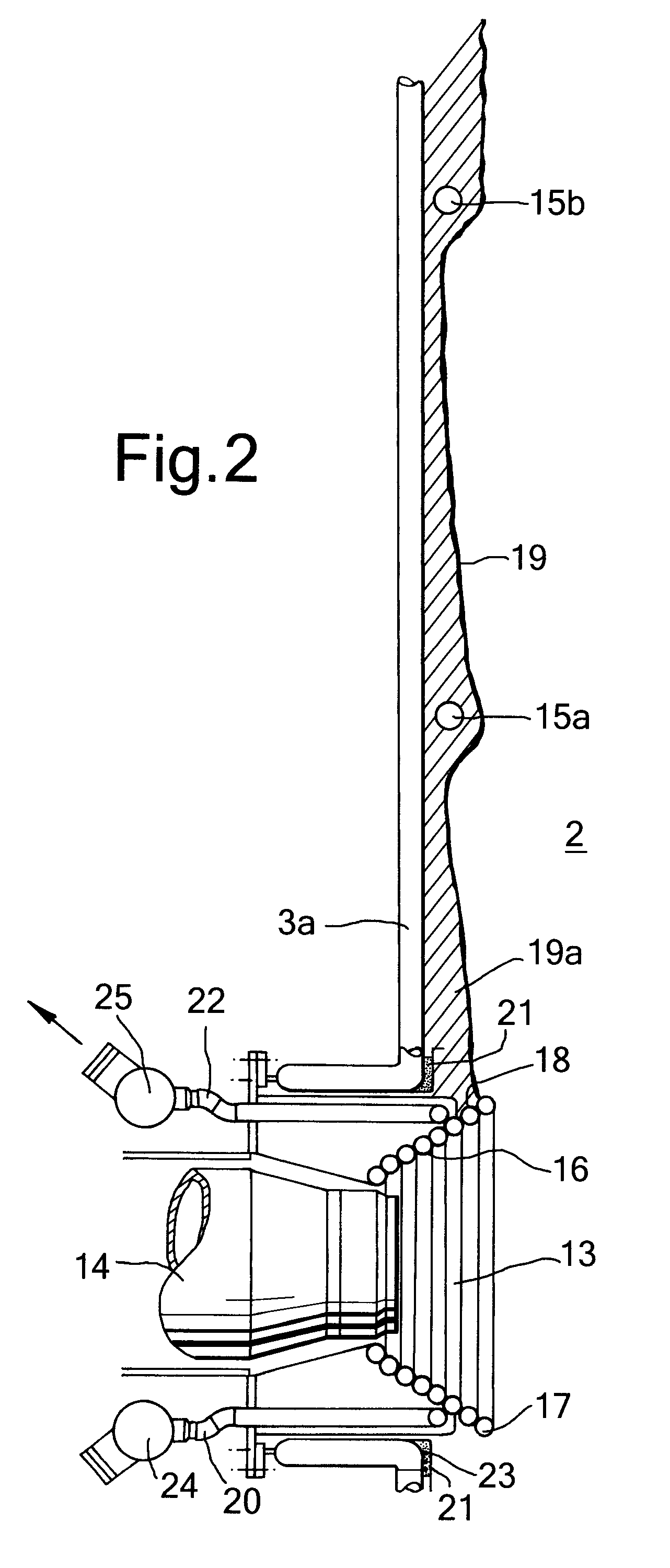

[0016]In a preferred embodiment, the present invention provides a slag deflector above one or more openings in a tubular membrane wall of a gasification reactor. The upper end of the slag deflector may be positioned between 0.1 and 3 times the width of the opening above the upper end of said opening. The slag deflector may be a rim attached to the membrane wall. The rim may be provided with a refractory coating. The deflector may be a conduit attached to the membrane wall provided with an inlet end for a cooling medium and an outlet end for used cooling medium. Said conduit may have a part located at a higher elevation above the opening and lower parts of the conduit extending side ways, such that in use at least part of the downwardly flowing slag is deflected away from the opening. The conduit may be provided with a refractory coating.

[0017]The slag deflector may be made from a low alloy steel with a Cr content up to 5 wt % or a high alloy steel with Cr content above 15 wt %.

[0018...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com