Apparatus for Removing Material, Use of Gas Inclusions in an Abrasive Liquid and Process for Grinding and/or Polishing Surfaces

a technology of gas inclusions and abrasives, which is applied in the direction of abrasion apparatus, metal-working apparatus, manufacturing tools, etc., can solve the problems of inability to use the entire workpiece, inability to continuously transition from grinding to polishing, and large amount of material removal, so as to achieve the effect of reducing the amount of material removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

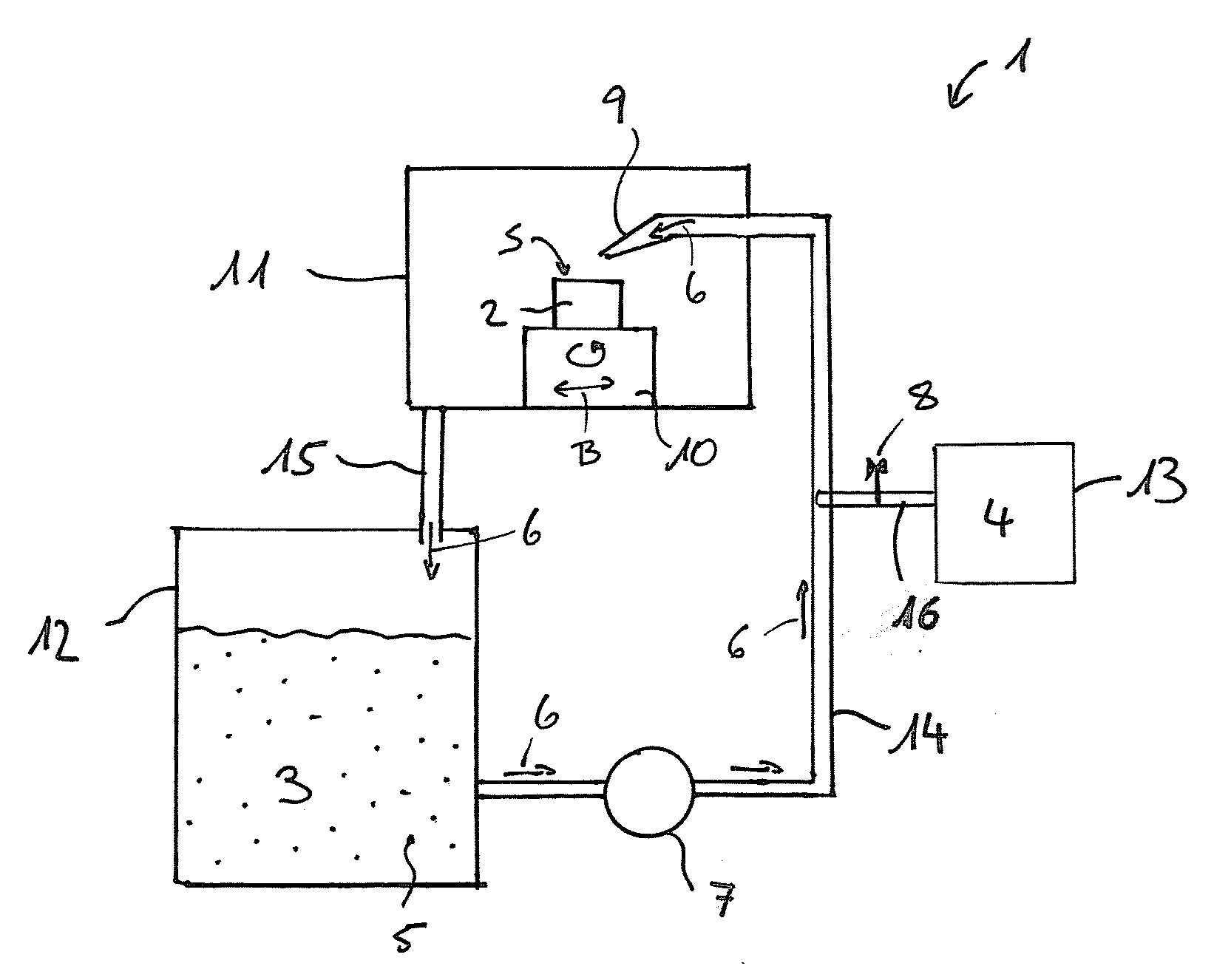

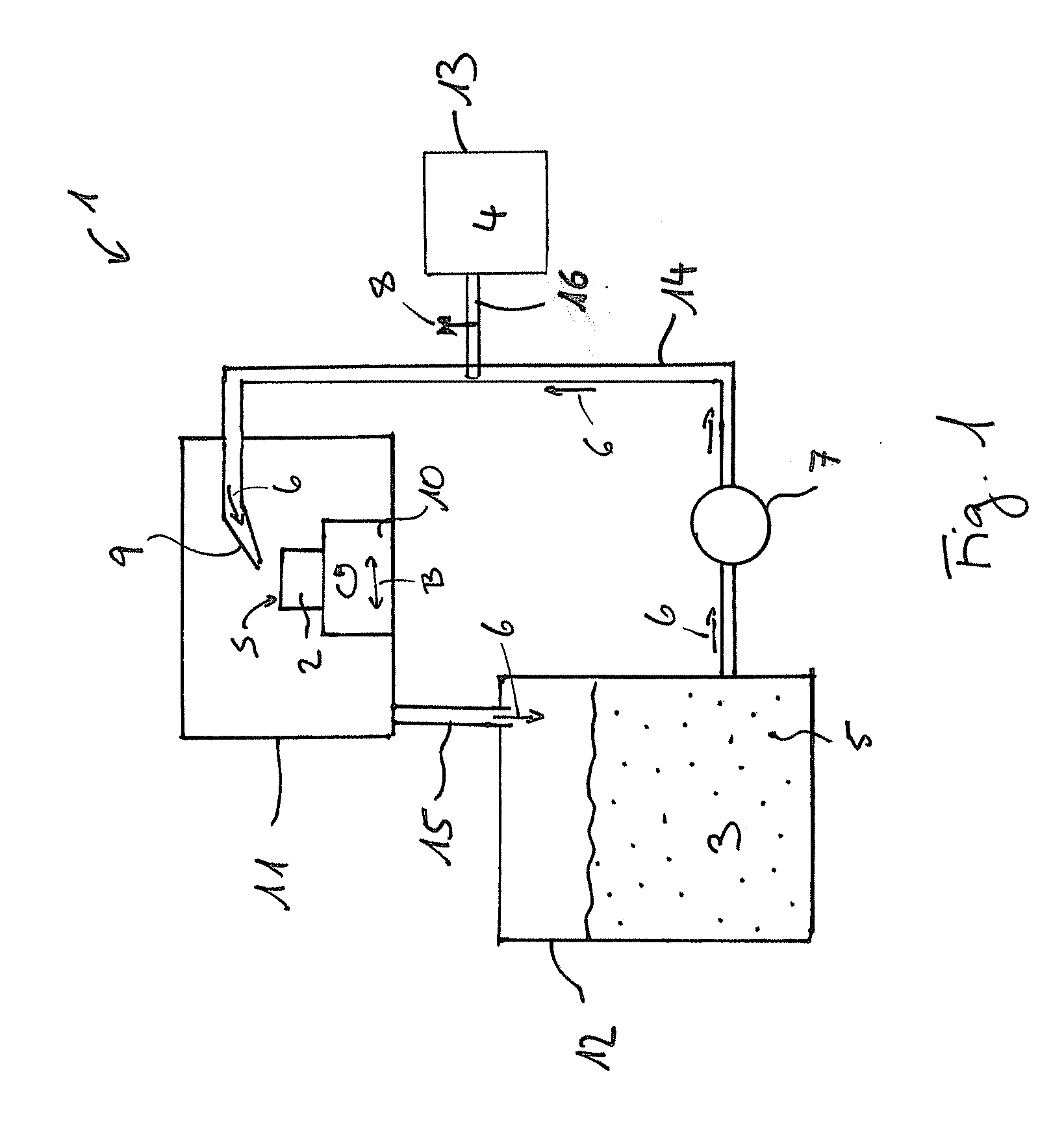

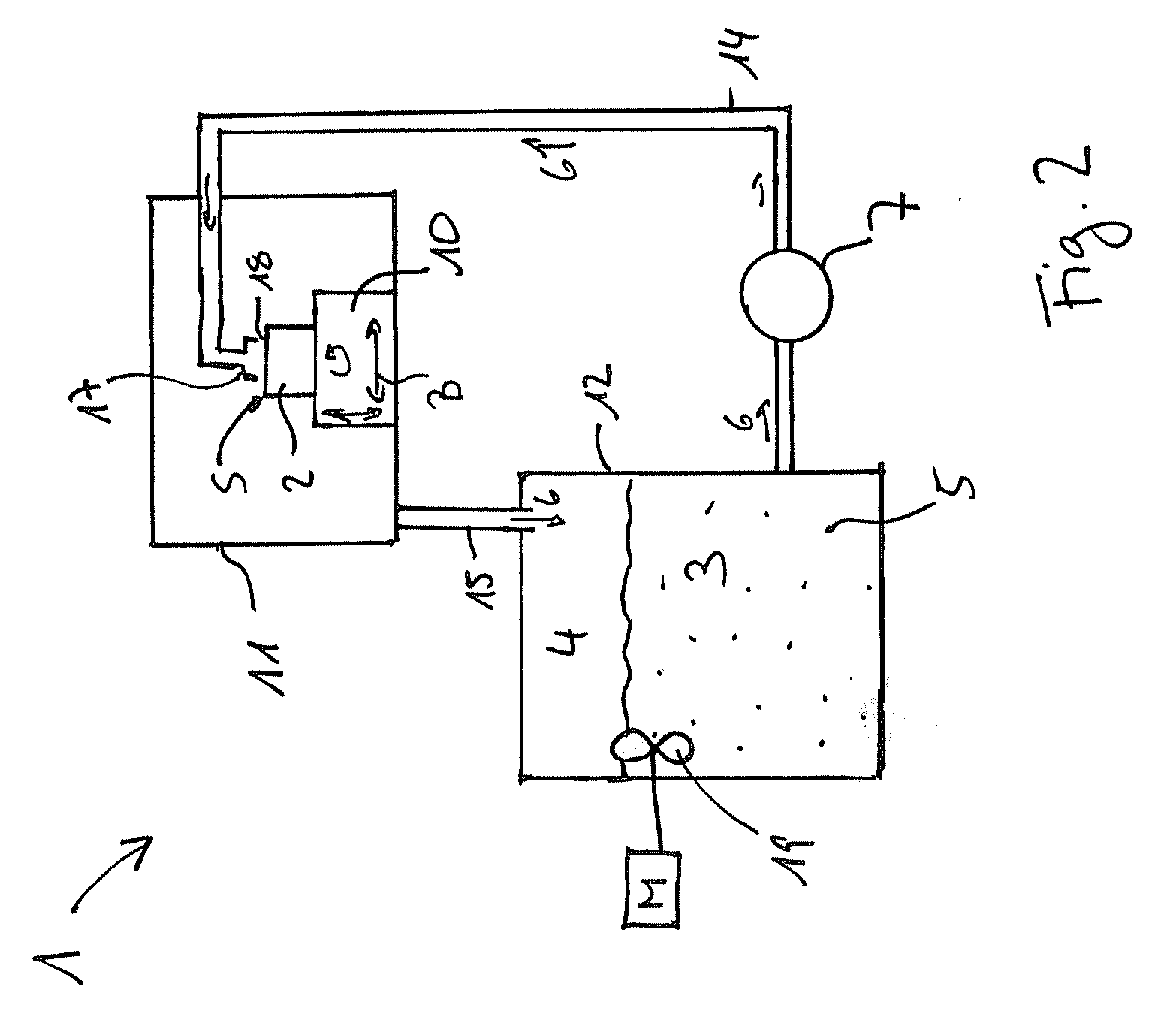

[0048]FIG. 1 diagrammatically depicts a first exemplary embodiment of the invention. A workpiece 2 is located on a holder 10 in a closed vessel 11. The surface S which is to be ground and polished is on the top side of the workpiece 2. The holder 10 can be displaced along a longitudinal axis and rotated about a vertical axis. The movement of the holder 10 is indicated by the arrows B.

[0049]A liquid 3, in this example water, is located in a liquid tank 12. Abrasive particles 5 have been added to the water 3 in a concentration of 10% by weight. Abrasive particles 5 of silicon carbide with a grain size of 7 (m diameter are used. The abrasive liquid 3 is delivered by a pump 7 through the delivery line 14 in the direction indicated by the arrows 6. The delivery pressure is 12 bar.

[0050]The removal of material takes place at room temperature, i.e. at approx. 21° C. The mechanical loading can heat the abrasive liquid to approx. 25° C., which, however, has no adverse effect on the material-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean grain diameter | aaaaa | aaaaa |

| mean grain diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com