Rocker arm for valve actuation

a rocker arm and valve technology, applied in valve arrangements, machines/engines, mechanical equipment, etc., can solve the problems of high amplitude vibration force to react on rocker arms and valve system components, engine block and cylinder head castings are complicated with structure, and achieve the effect of increasing airflow into the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

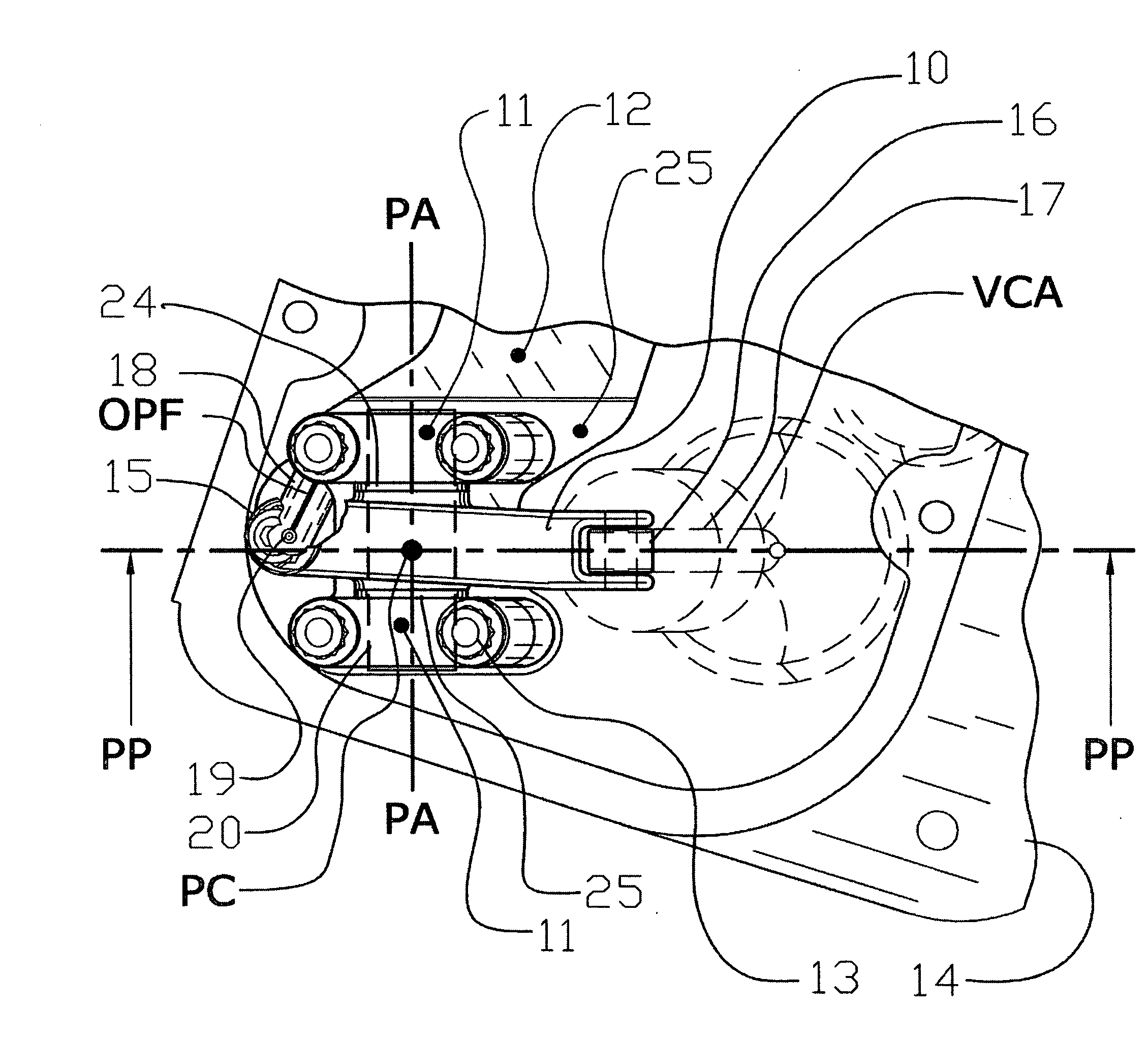

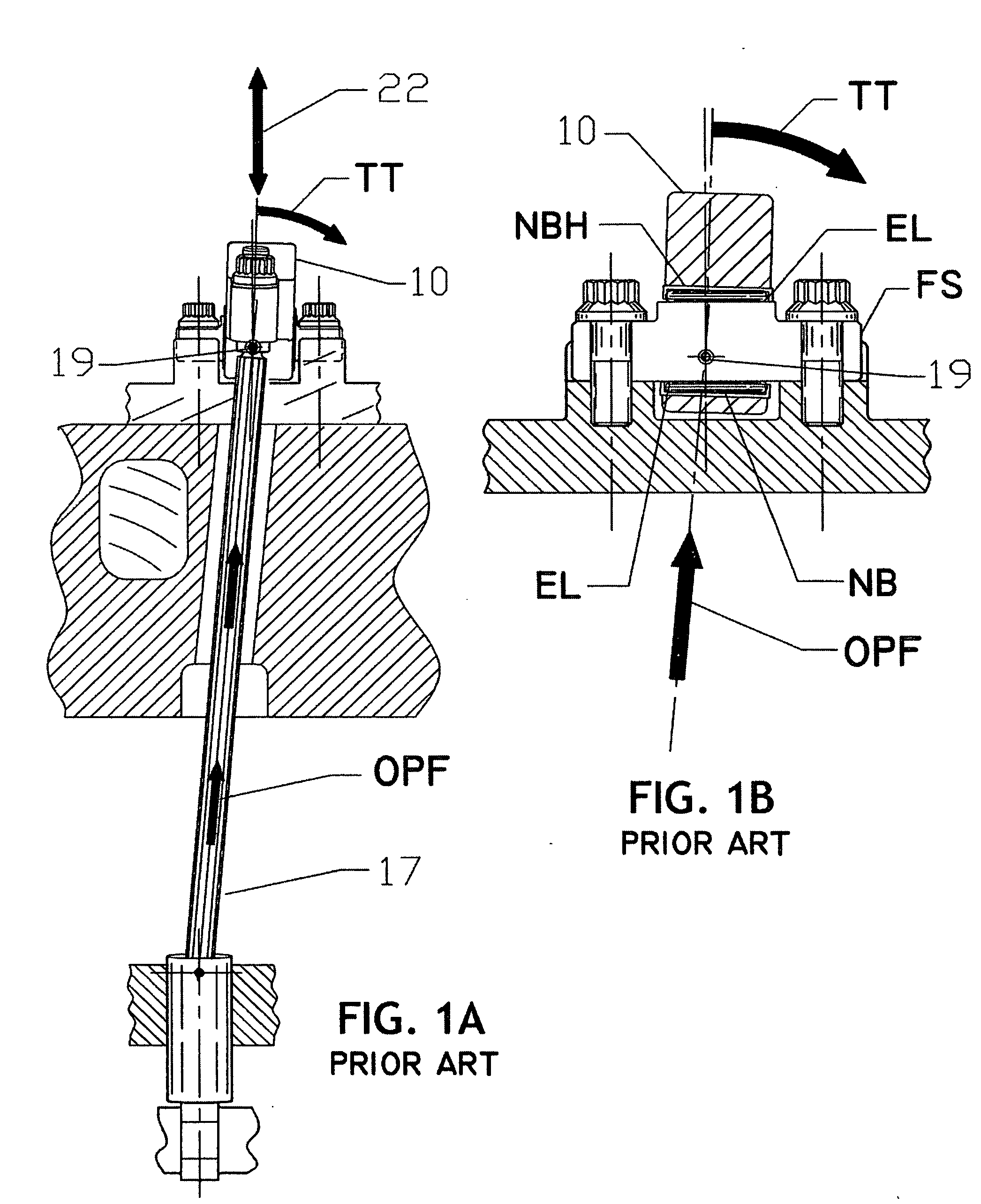

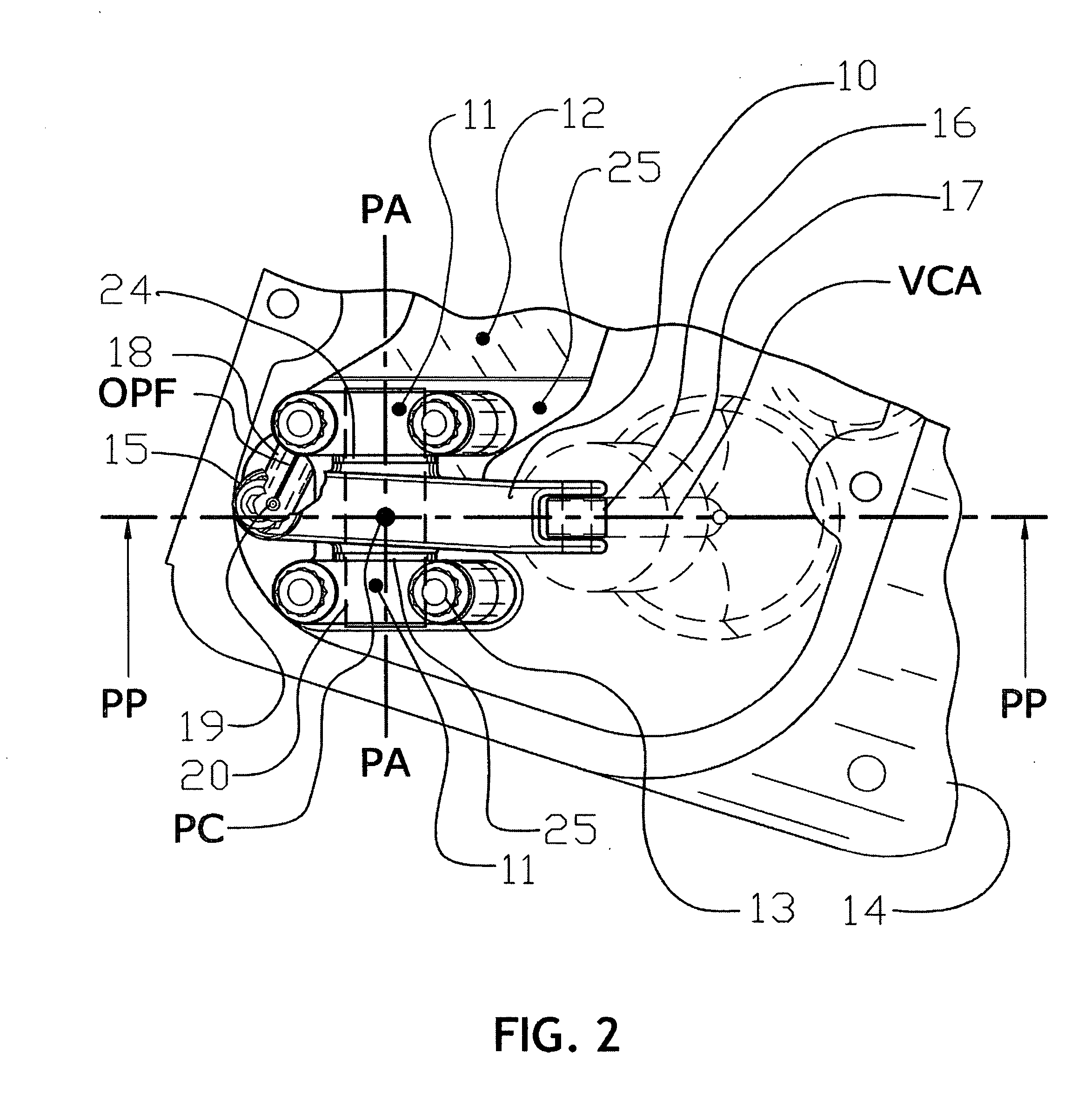

[0030]The improved system embodies a rocker arm beam having journals, (cylindrical pivot projections, one each side), extending from each side of the rocker arm body making a single whole structure, supported and pivoting in outboard bearings and bearing mounts to guide the pivot motion of the rocker arm and journal as a whole. The improved rocker arm embodiment with journals and outboard bearings embodies a widely spaced dual bearing support, thus eliminating common installation of a pivot bearing or bearings centered within the rocker arm beam body. This improvement provides wide stable resistance to rocker beam deforming torsional forces. The improved stability provides a rocker arm pivot system having accurate and precise valve actuation. Improving valve system stability and precision leads to higher potential engine speed and improved engine performance and reduced or eliminated unwanted valve train excitation caused by vibration amplitude excesses.

[0031]A detailed description ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com