Battery module

a battery module and battery technology, applied in the field of batteries, can solve the problems of difficult to apply uniform pressure to each battery, battery capacity loss and cycle performance deterioration, and the pressure applied tends to vary between the batteries positioned at both ends and those positioned in the vicinity of the center, so as to prevent the distance between the electrodes from increasing, reduce the loss of battery capacity and cycle performance deterioration, and efficiently release the effect of high-rate discharg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

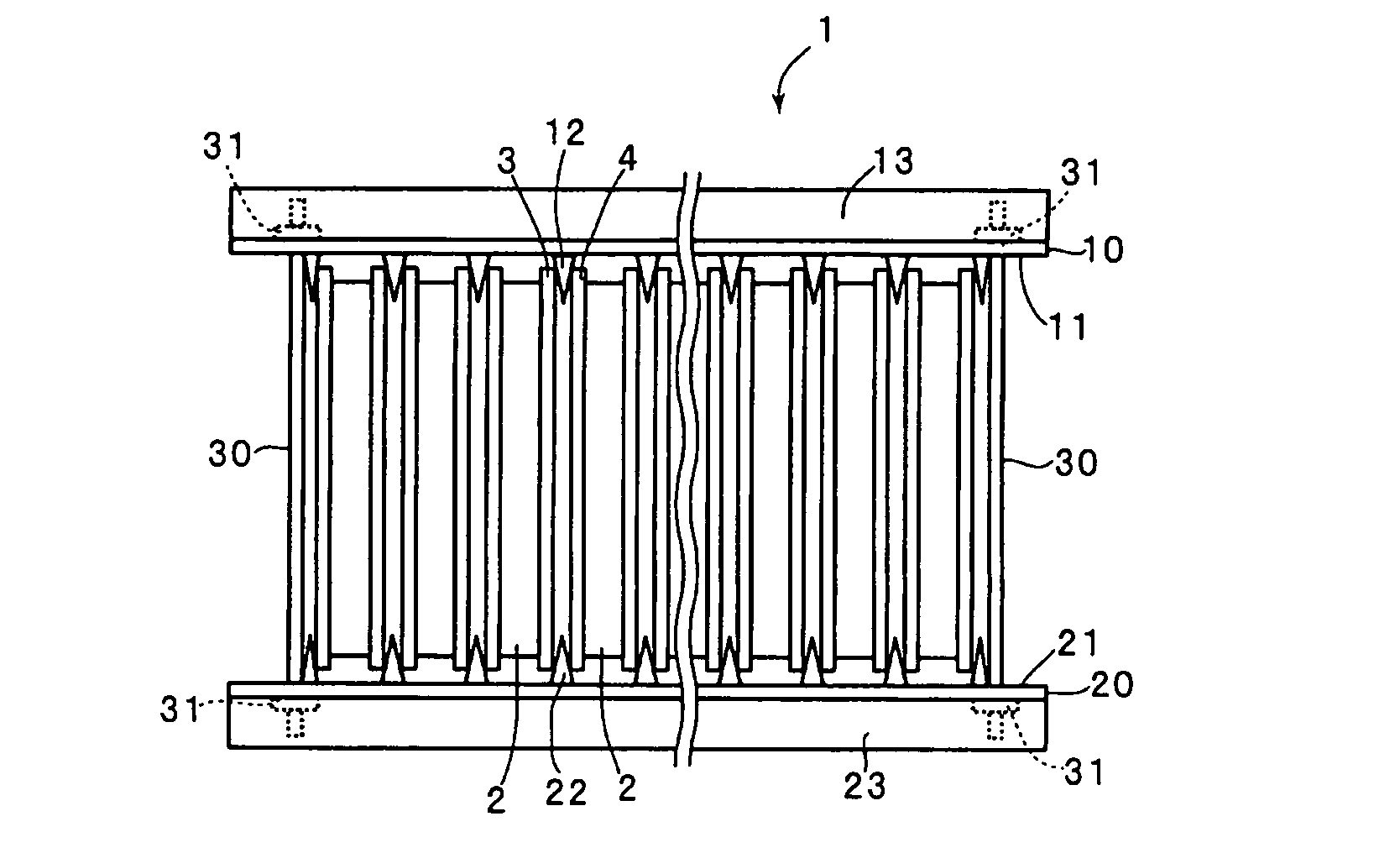

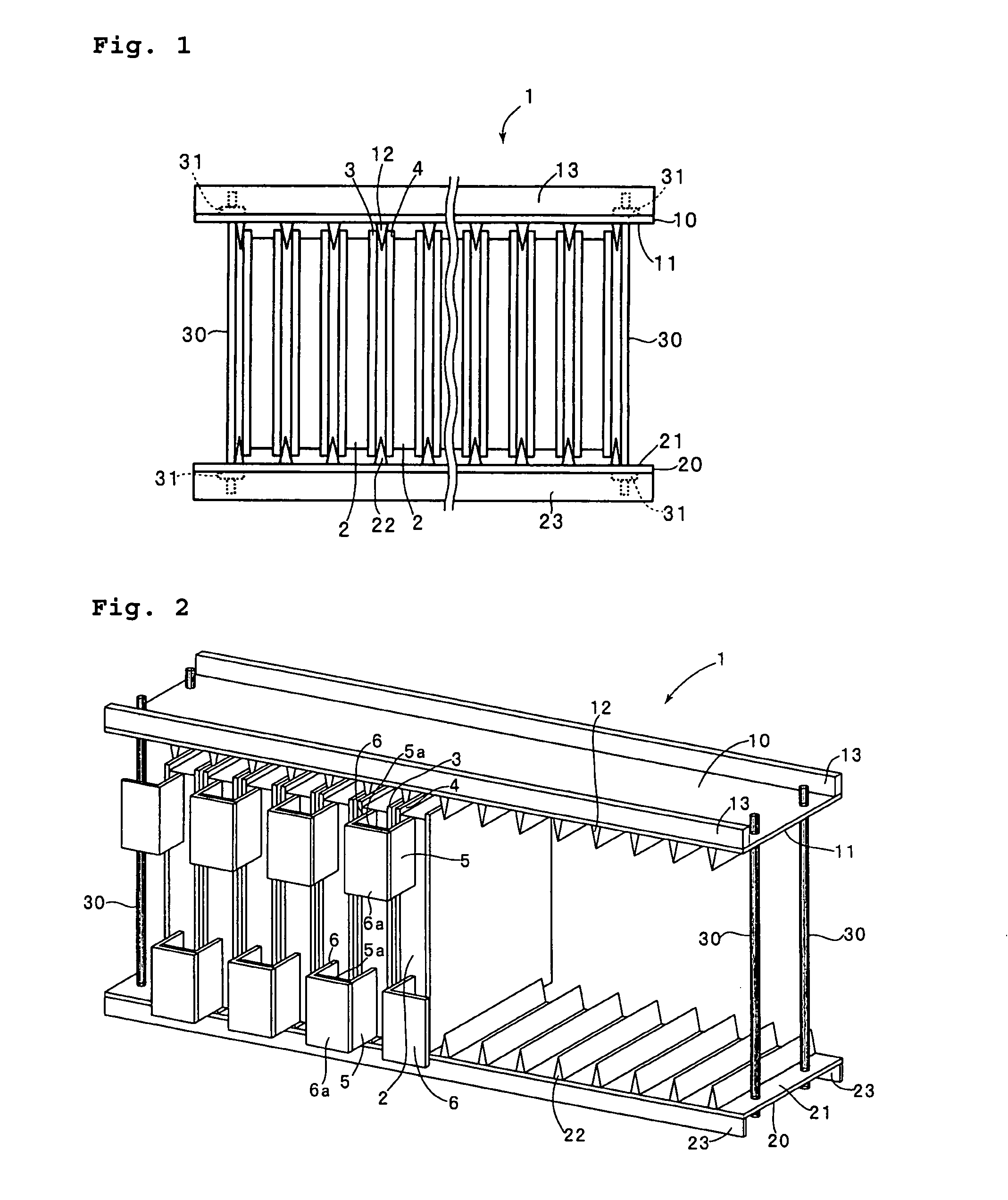

[0053]FIG. 1 is a side view of the battery module prepared in Example 1, and FIG. 2 is a perspective view thereof.

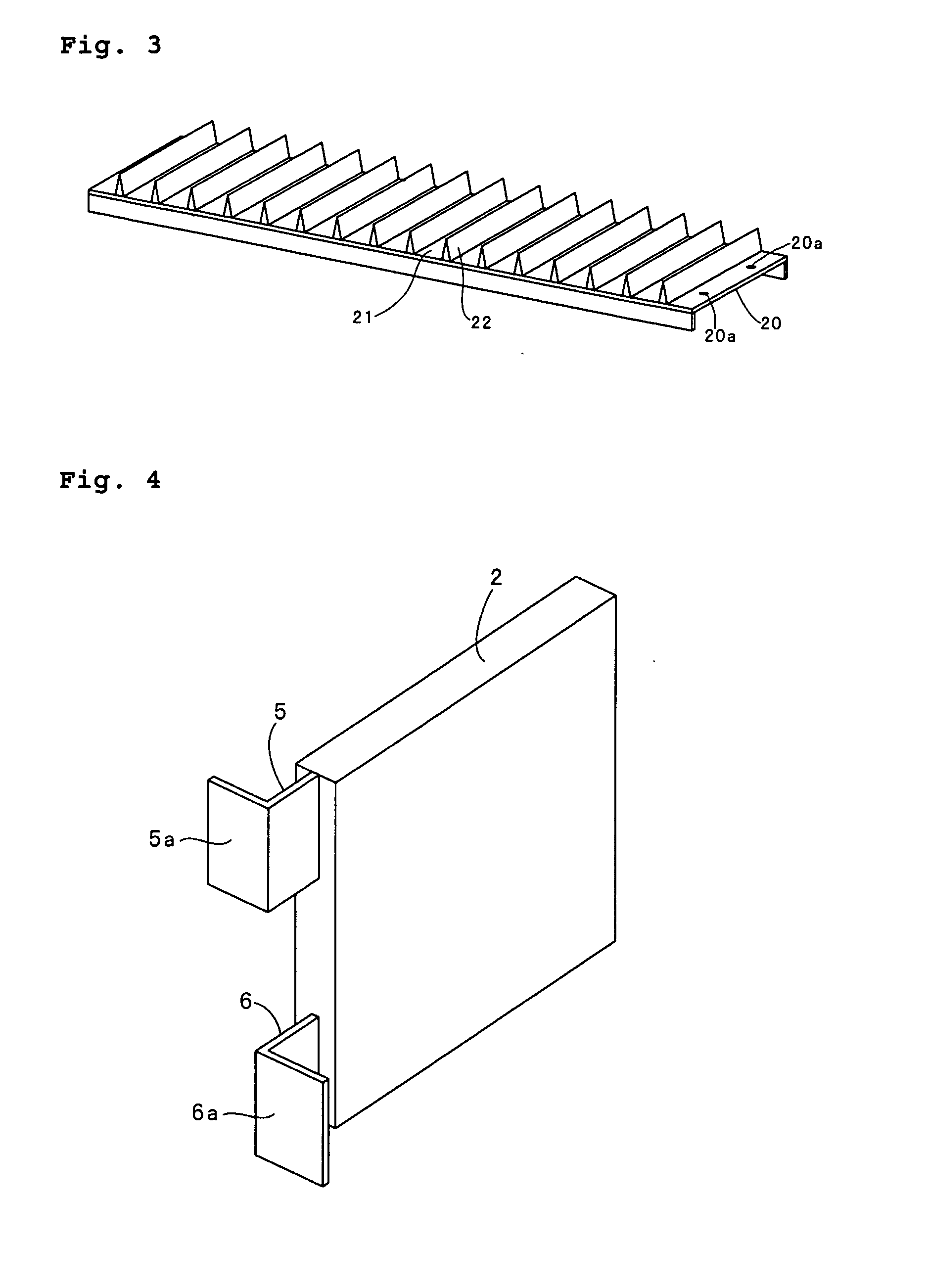

[0054]As illustrated in FIGS. 1 and 2, the battery module of the present example comprises stack electrode batteries 2 stacked in a thickness direction, and two plates 3 and 4 are inserted between each of the batteries 2. Each of the plates 3 and 4 is formed of stainless steel and has a width of 100 mm, a height of 115 mm, and a thickness of 2 mm.

[0055]A pair of frame members 10 and 20 are provided so as to sandwich the batteries 2 along a direction perpendicular to the stacking direction of the batteries 2. The frame members 10 and 20 have respective opposing surfaces 11 and 21 opposed to each other, and the frame members 10 and 20 are disposed so that the opposing surfaces 11 and 21 face each other. Wedge-shaped spacers 12 and 22 are provided on the opposing surfaces 11 and 21, respectively. The wedge-shaped spacers 12 and 22 have a triangular prismatic shape. Each of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com