Method And Apparatus For Protecting Against Ballistic Projectiles

a technology of ballistic projectiles and shields, applied in protective equipment, protective garments, armour plates, etc., can solve the problems of inflexible solid plate designs, high specific energy upon initial impact, and inaccessibility to details, etc., to achieve economical and rapid deployment to the armed forces, reduce the effect of manufacturing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

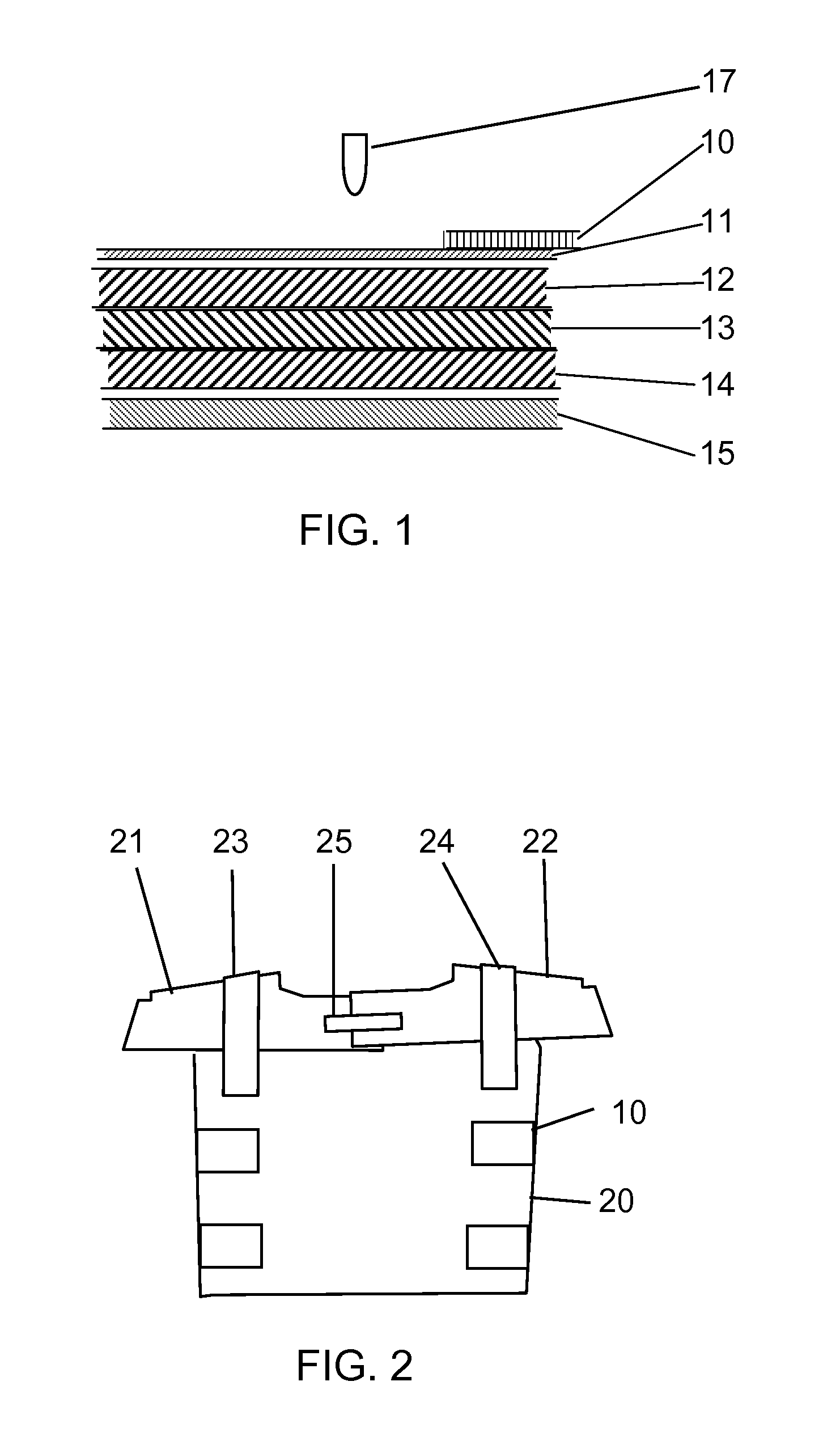

[0040]The first embodiment is a flexible bullet proof vest which provides the wearer protection from high velocity, high power rifle fire to within the inner surface deflection limit of 4.4 centimeters (1.73 inches) specified by the United States National Institute of Justice (NIJ Standard 0101.04). By high velocity, high power rifle, we specifically consider the standard NATO 7.62×51 mm cartridge, which is a common threat in current warfare. This first embodiment of the invention is designed to protect to NIJ Standard 0101.04 Type III which protects against 7.62 mm Full Metal Jacketed (FMJ) bullets (U.S. Military designation M80), with nominal masses of 9.6 grams (148 grains) at a reference velocity of 847 meters / second (2780 ft / s). The concept of flexibility is important in bullet proof vests. A solid or stiff vest is extremely uncomfortable to a human user, and can result in the vest not being worn. Non-flexible vests exist, but tend to be constructed to provi...

second embodiment

Description of Second Embodiment of the Invention

[0068]A second embodiment of the invention will now be disclosed. It is also a bullet proof vest, hereafter referred to as vest. This second embodiment differs from the first embodiment in the construction of the ballistic layers, which will be described in detail. However the principles of operation and function are the same as in the first embodiment. The general assembly and construction of the final garment is essentially similar to that of the first embodiment and will not be described here.

[0069]The vest is constructed of five layers. There are three ballistic function layers, as with the first embodiment. The outermost first layer (11) and innermost fifth layer (15) are the same as described in the first embodiment.

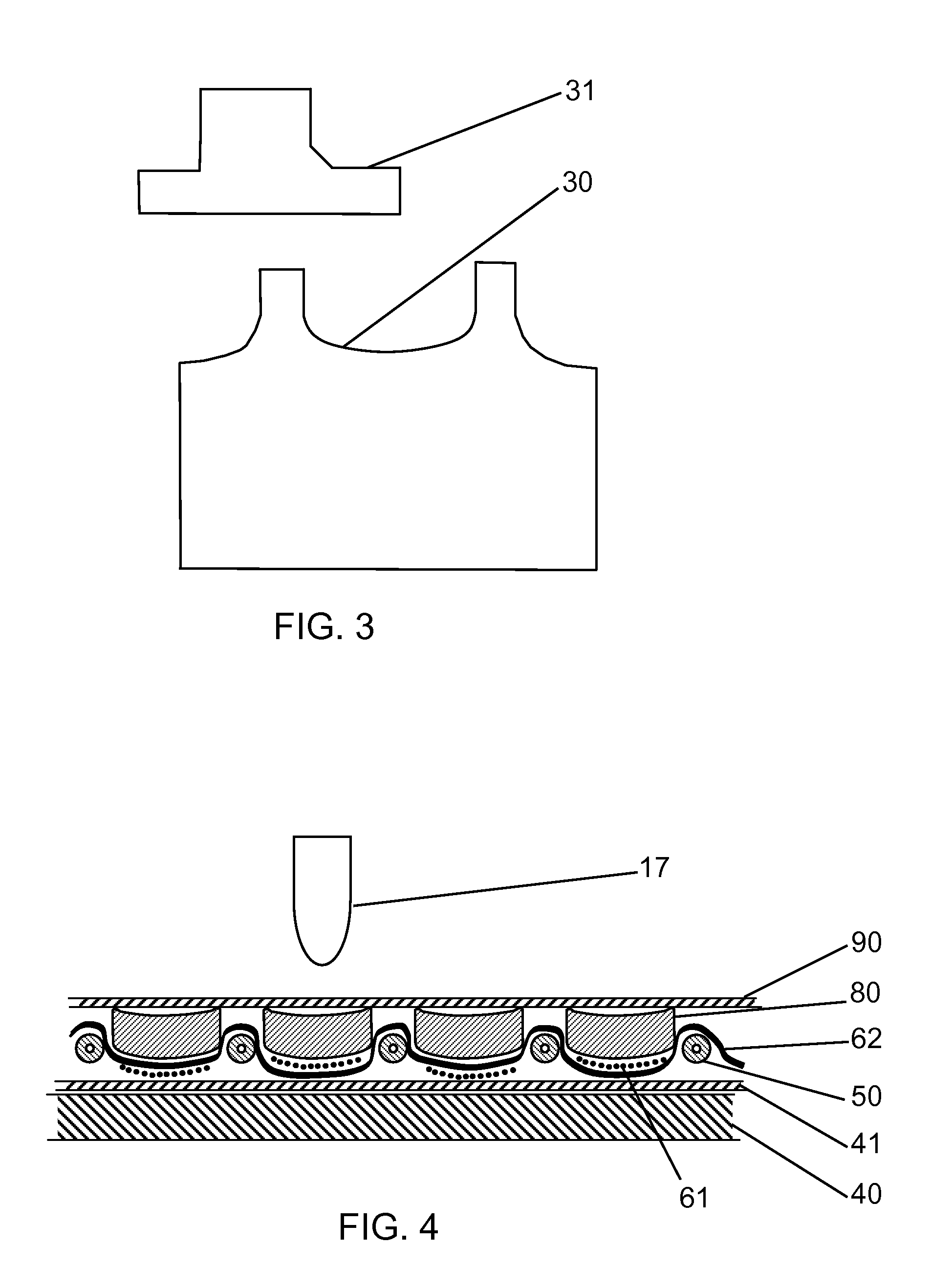

[0070]Details of the construction of the first ballistic layer of the second embodiment vest are shown in the cross section in FIG. 10. A plurality of square cross section discs (103) arranged in a regular square mat...

third embodiment

Description of Third Embodiment of the Invention

[0078]A third embodiment of the invention will now be disclosed. It is also a bullet proof vest, hereafter referred to as vest. This third embodiment differs in construction of the ballistic layers, one of which will be described in detail, however the principles of operation and function are the same as in the first and second embodiment. The general assembly and construction of the final garment is essentially similar to that of the first and second embodiment and will not be described.

[0079]The vest is constructed of five layers. There are three ballistic function layers, as with the first embodiment. The outermost first layer (11) and innermost fifth layer (15) are the same as described in the first embodiment.

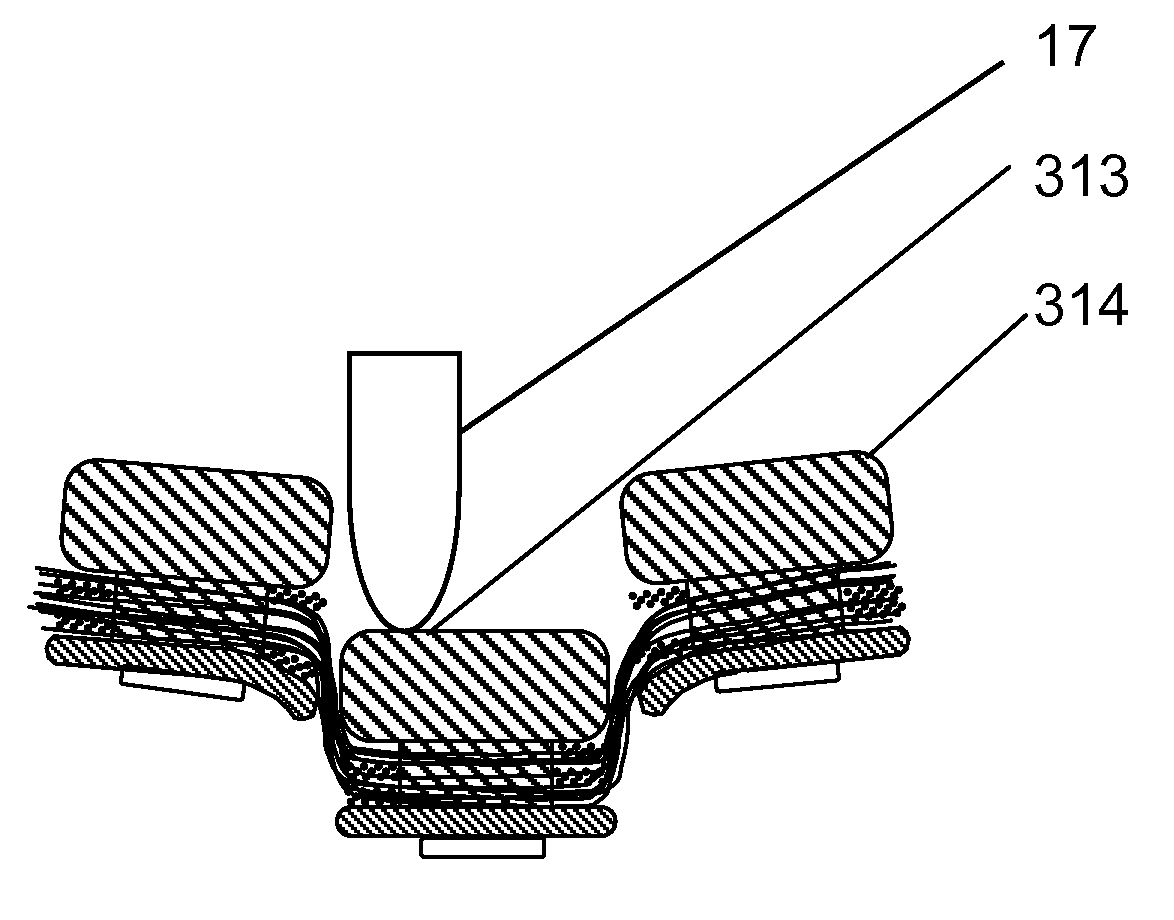

[0080]Details of the construction of the first ballistic layer of the third embodiment vest will now be described with reference to FIGS. 11, 12 and 13.

[0081]A plurality of square cross section multi-component discs (303) arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Momentum | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com