Method for manufacturing semiconductor package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

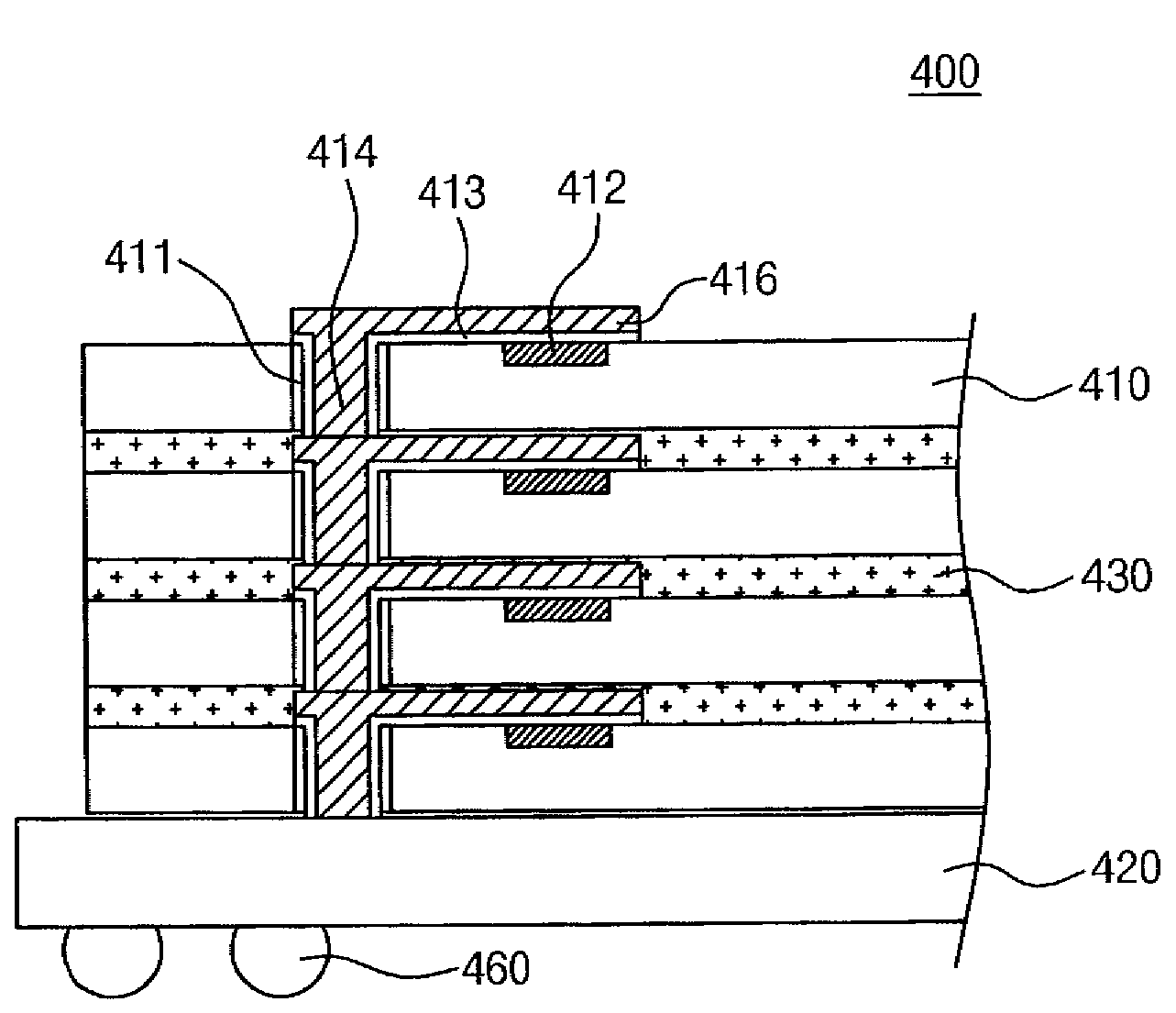

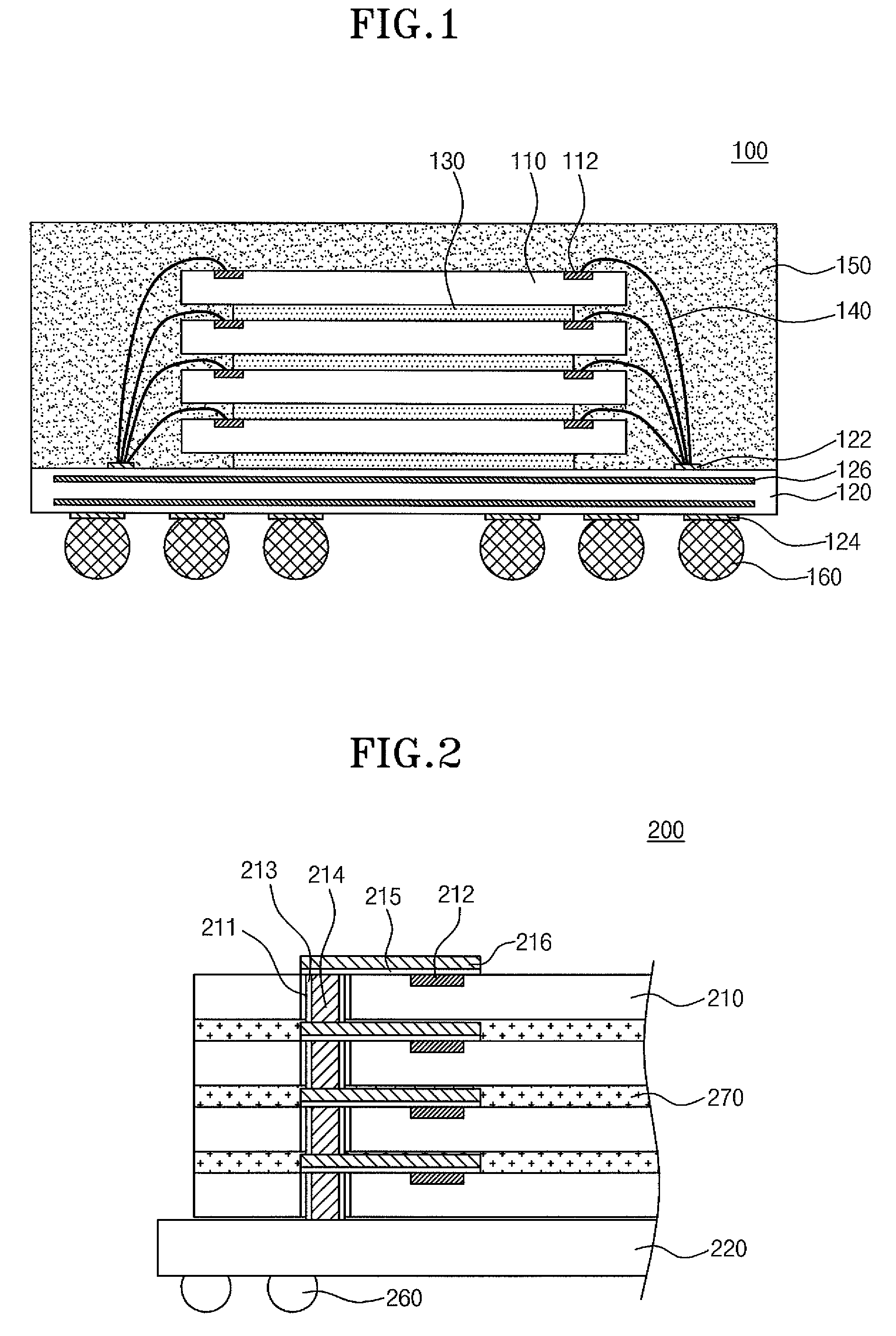

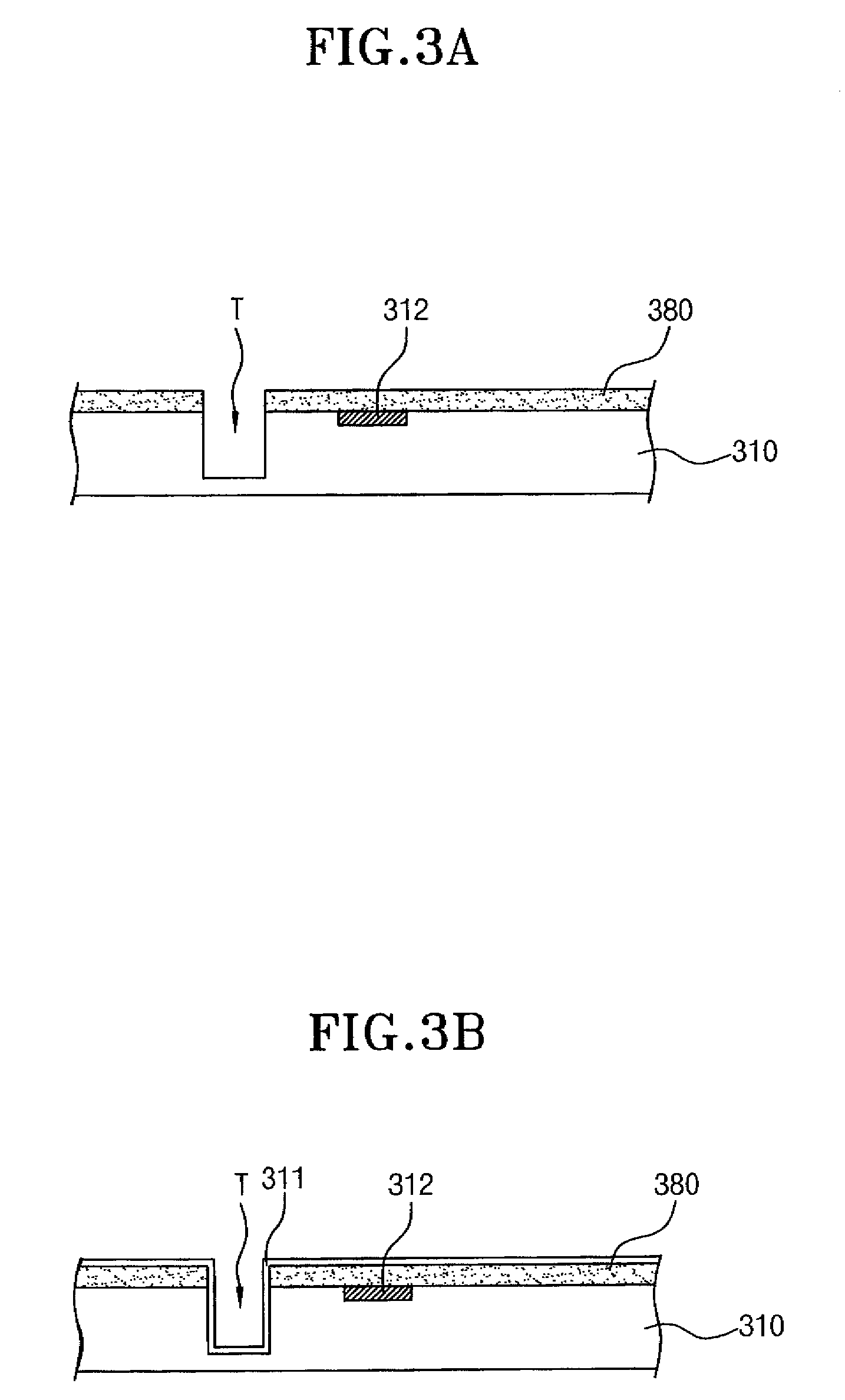

[0042]A preferred embodiment of the present invention is directed to a method for manufacturing a semiconductor package in which a through silicon via and a redistribution layer, connecting the through silicon via to a bonding pad, are formed simultaneously. Further, a preferred embodiment of the present invention is directed to a method for manufacturing a semiconductor package in which semiconductor chips are stacked vertically such that mold parts are formed on both upper and lower surfaces of the semiconductor chip formed with the through silicon via and the redistribution layer.

[0043]Therefore, in an embodiment of the present invention, since the through silicon via and the redistribution layer are formed not separately but simultaneously, it is possible to simplify the process and reduce manufacturing costs.

[0044]Also, in an embodiment of the present invention, because the stack type semiconductor package is realized by stacking the semiconductor chips formed with the mold par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com