Pressure relief valve for structure

a pressure relief valve and structure technology, applied in the field of structures, can solve the problems of severe building damage, roof blowing off, and building wind damage, and achieve the effects of reducing the possibility, reducing the possibility, and instant relief of windstorm-induced pressure insid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

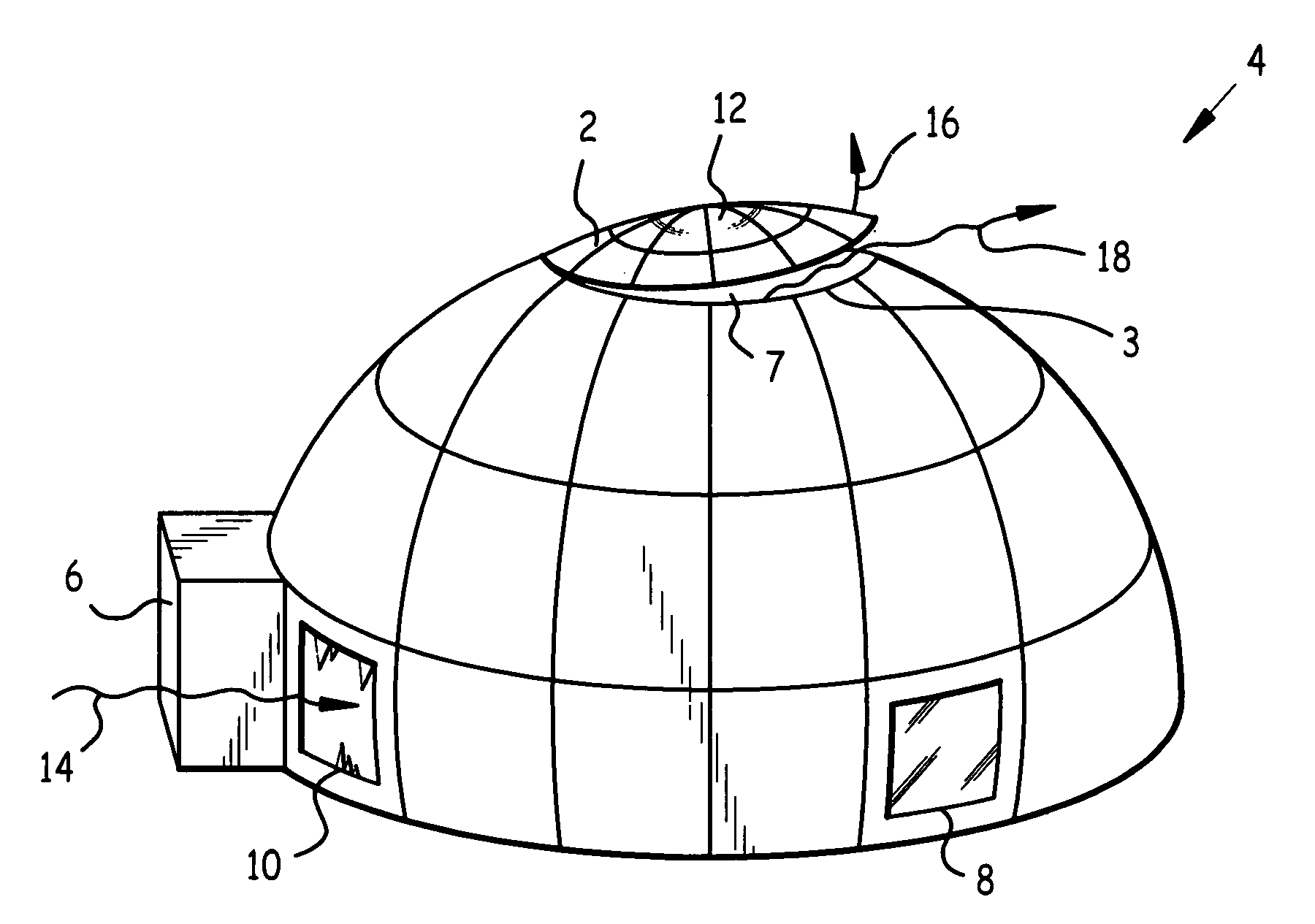

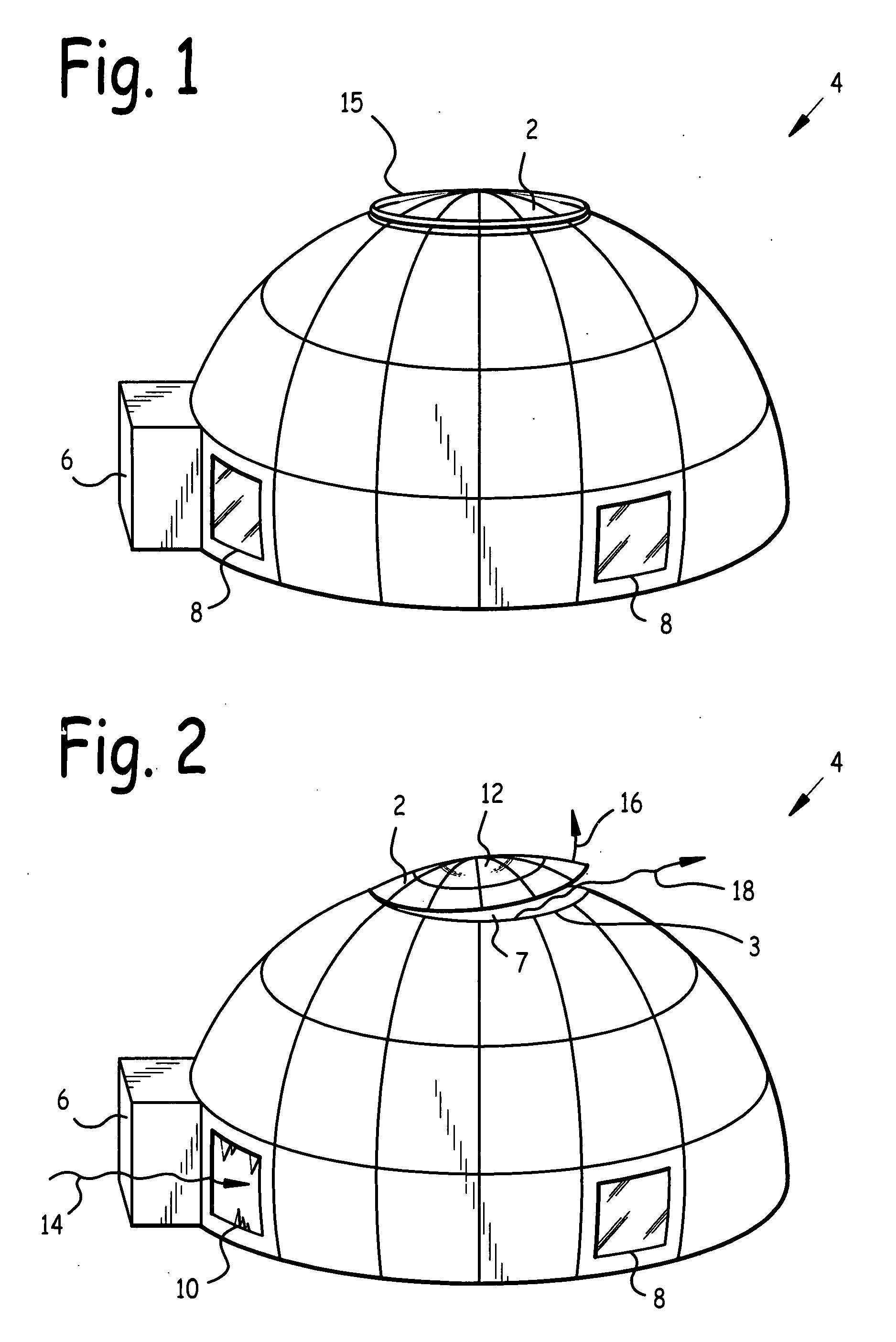

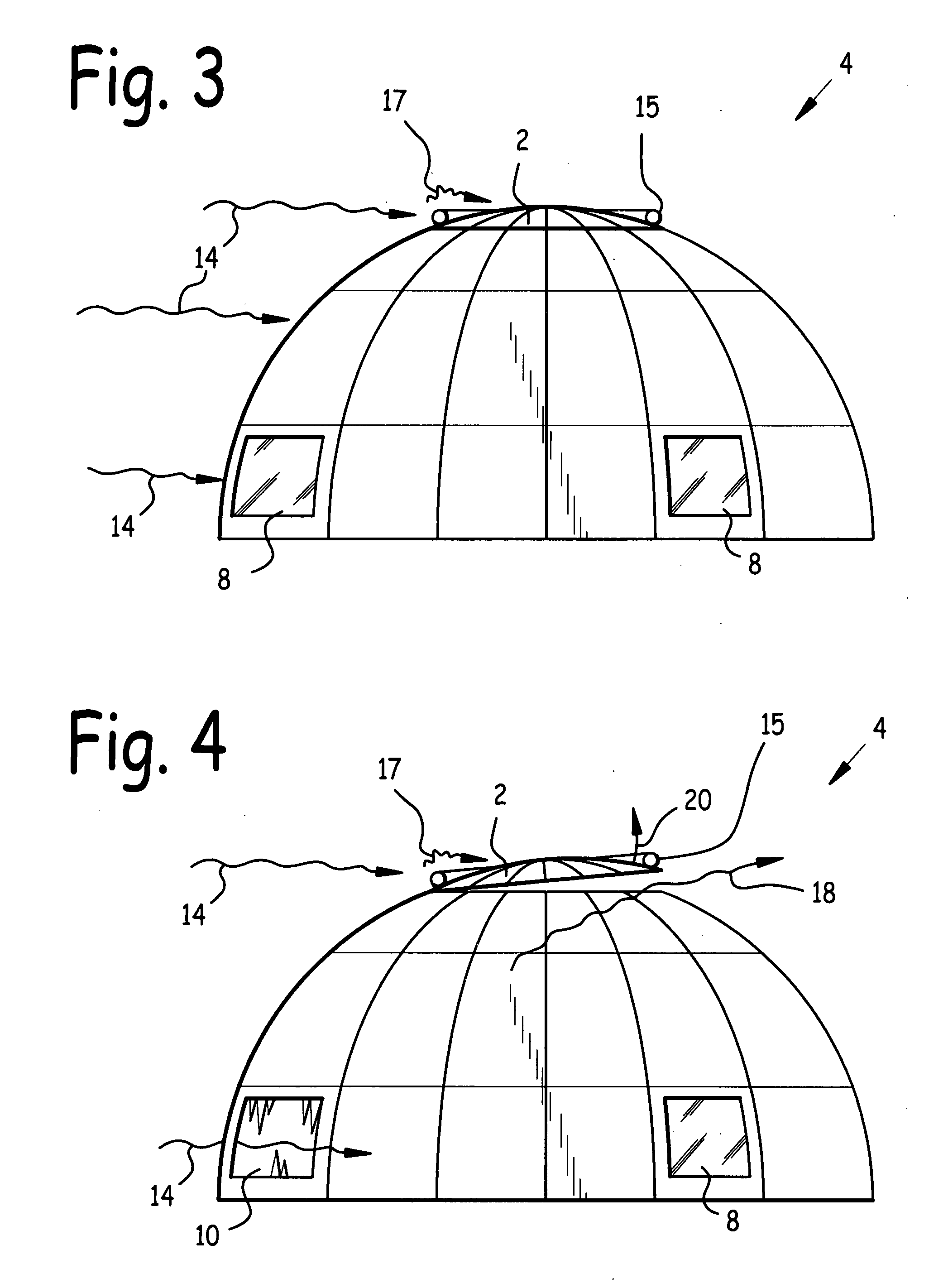

[0029]Referring now to FIG. 1, we observe a side isometric view of a pressure relief valve 2 mounted at the top of structure 4. Structure 4 comprises door 6 and windows 8. FIG. 2 is a side isometric view of valve 2 which has opened to relieve air pressure internal to structure 4. As may be observed in FIG. 2, valve 2 seats in valve seat 3, which is disposed around structure valve aperture 7. Spoiler 15 is disposed around the edge of valve 2. Unless opened by internal pressure within structure 4, valve 2 is normally spring-loaded, and / or urged by gravity, into the closed position depicted in FIG. 1. In the preferred embodiment, an internal structure pressure of as little as 1.5 pounds per square inch (psi) sufficed to open valve 2.

[0030]Referring now to FIG. 2, storm wind 14 has breached a window 8 such as may occur during a hurricane, and is now blowing into structure 4 via broken window 10. Valve 2 has opened against its spring-loaded mounting as indicated by arrow 16, and is permi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com