Lath support system

a technology of lath support and support rod, which is applied in the direction of walls, covering/linings, constructions, etc., can solve the problems of cracking of stone, plaster, or stucco, visible, unstable, and unattractive, so as to save labor costs, save installation time, and increase the coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

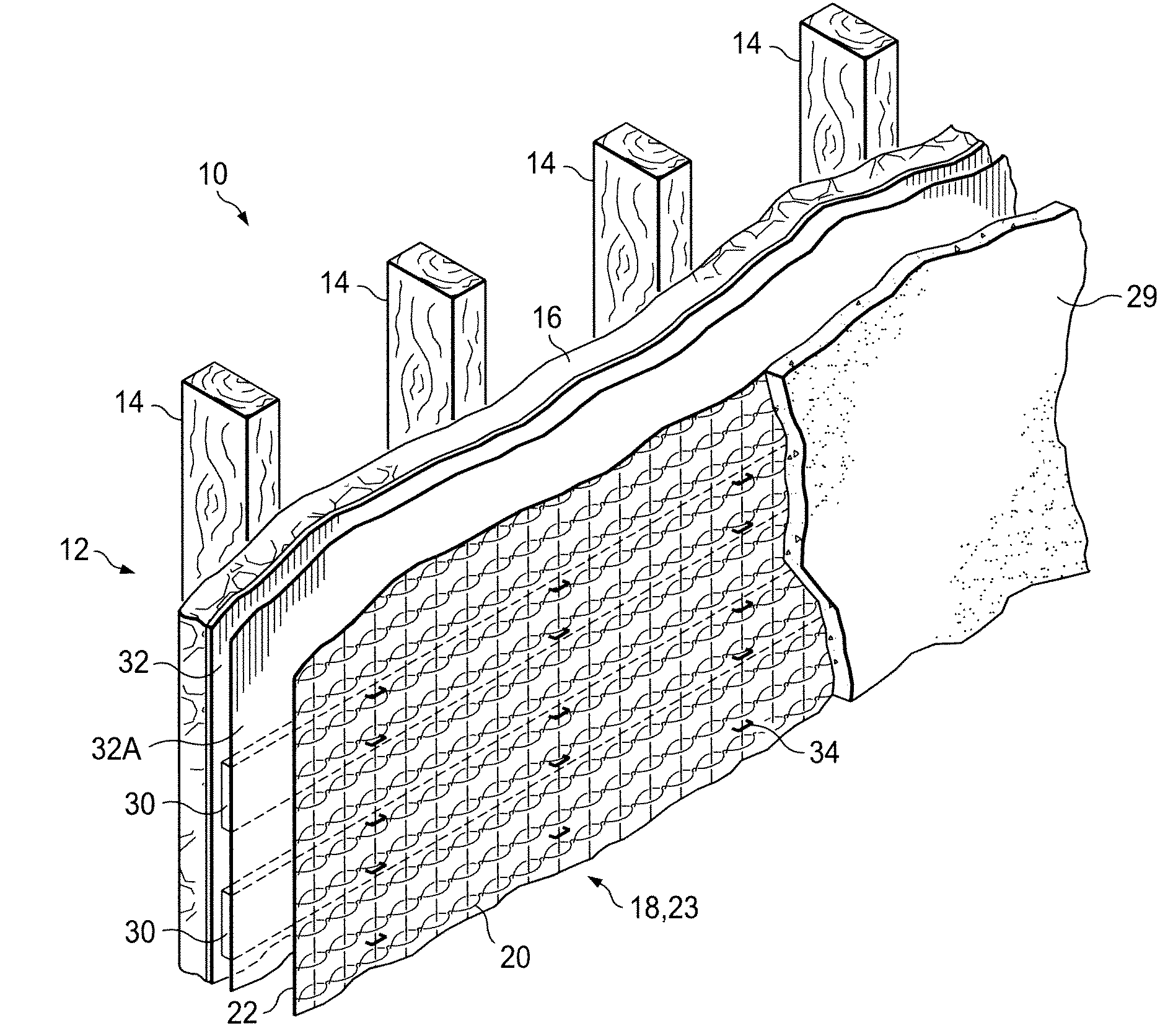

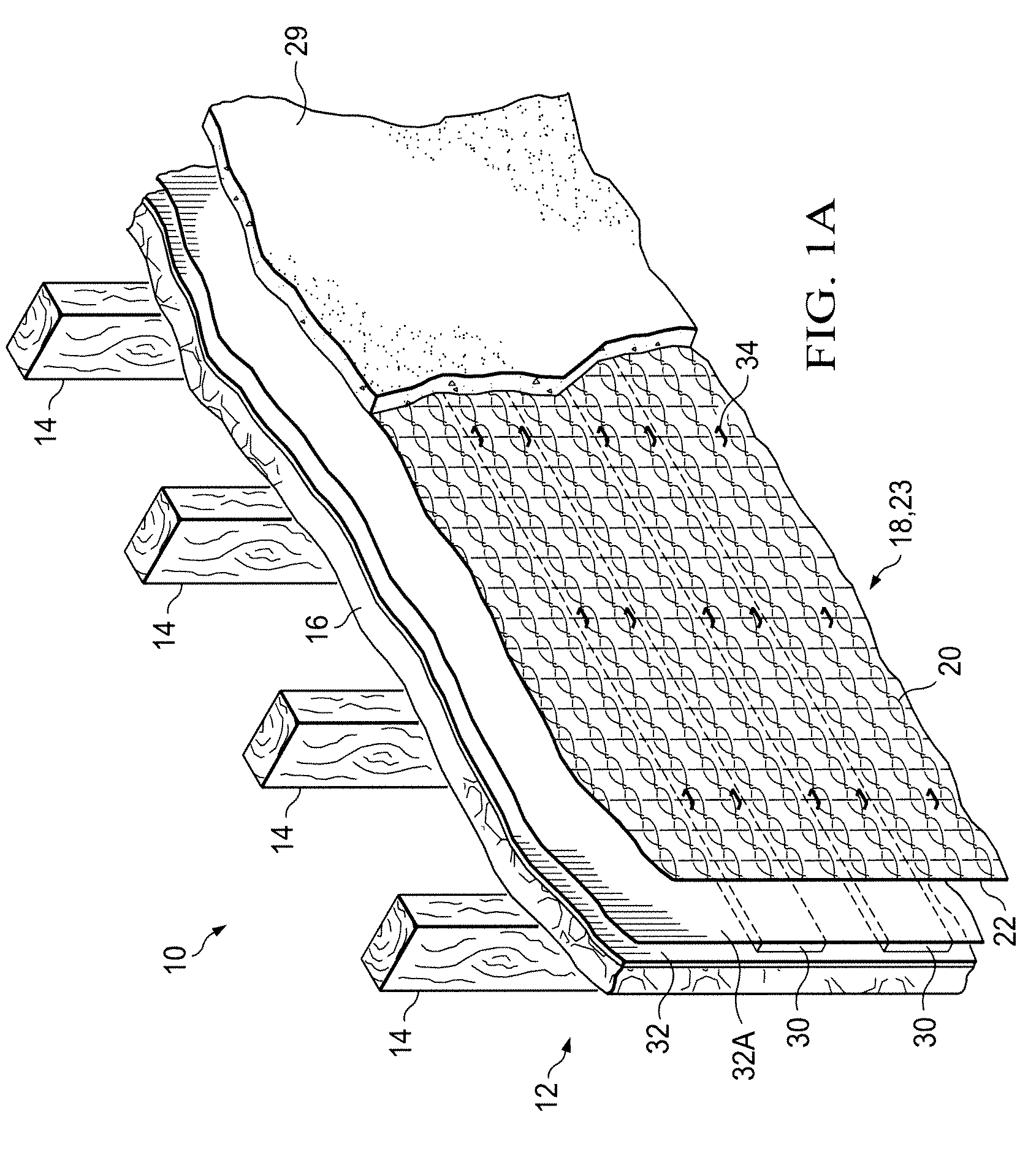

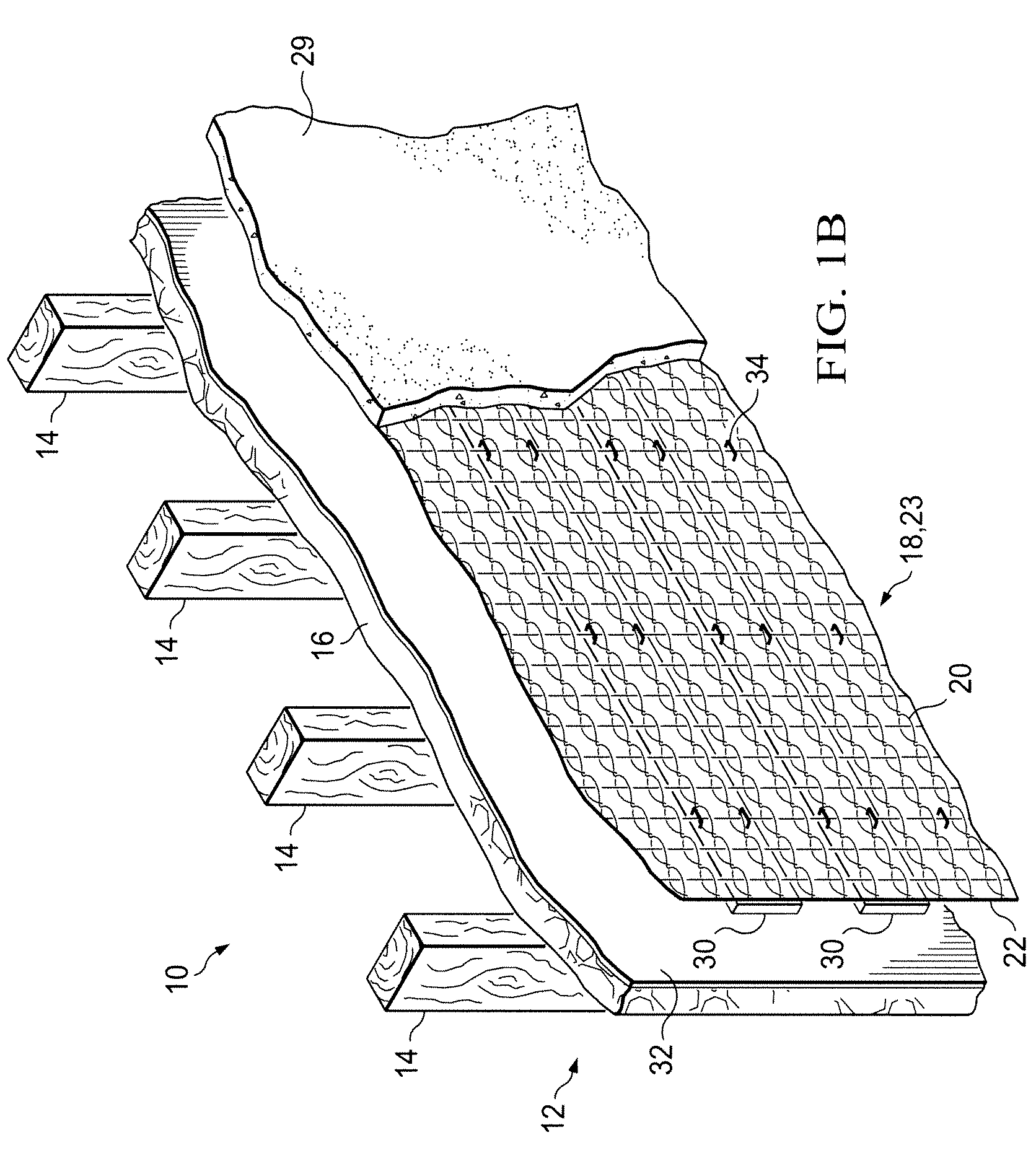

[0062]Referring now to FIG. 1B, the structural reinforcement system 10 of the invention is shown. Structural reinforcement system 10 is affixed to support structure 12. Support structure 12 typically is made up of a plurality of studs 14 which may be covered with sheathing 16. An example of sheathing 16 is oriental strand board (OSB). A lath 18 is located adjacent to support structure 12. Lath 18 has a front surface 20 and a rear surface 22.

[0063]In one embodiment (FIGS. 1A-6) lath 18 is a mesh structure 23. Mesh structure 23 may be a metal lath or a non-metallic lath. In the embodiment wherein lath 18 is a non-metallic lath, mesh structure 23 includes a first group of a plurality of strands 24 (best shown in FIGS. 3-6) that are generally parallel to one another, e.g., horizontal strands. Mesh structure 23 further includes a second group of strands 26 that are generally parallel to one another and transverse to the first group of plurality of strands 24, e.g., vertical strands. Firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap