Liquid tank, breather device, and exhaust gas purification device for engine

a technology of exhaust gas purification device and liquid tank, which is applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problem of liquid storage and flow ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

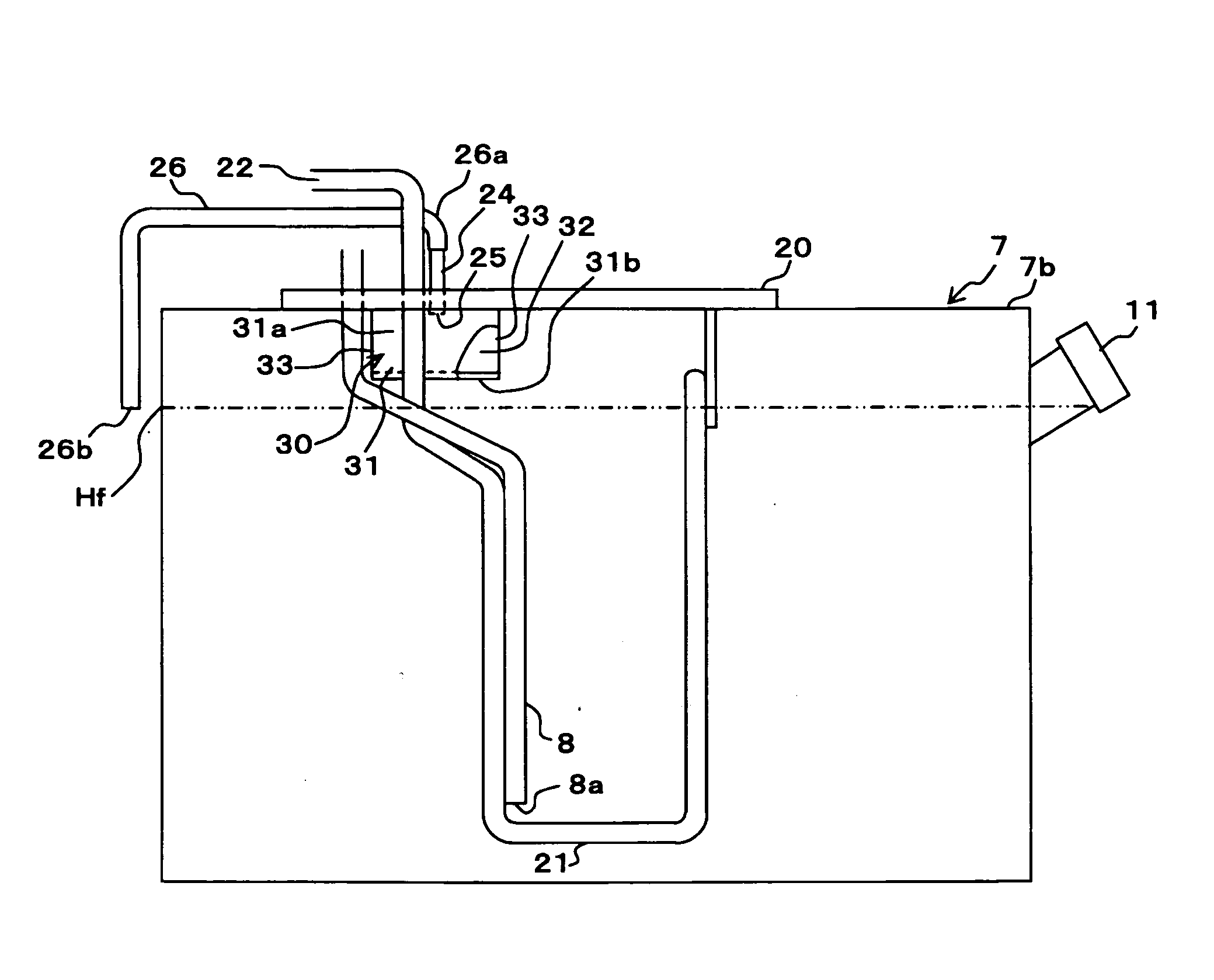

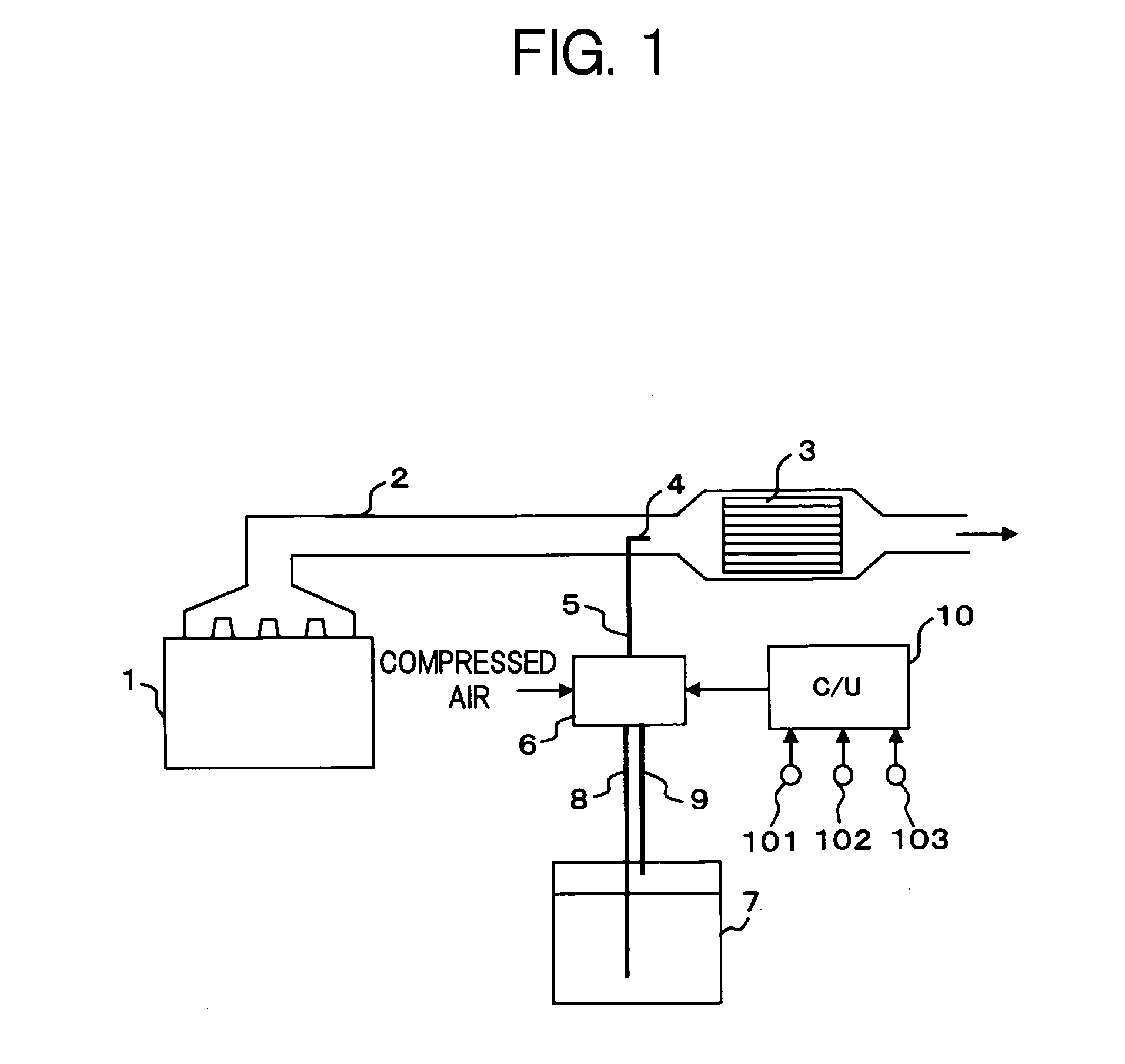

[0027]FIG. 1 is a schematic block diagram of an exhaust gas purification device for an engine, according to the present invention.

[0028]In the present embodiment, an engine 1 is a diesel engine, and is employed to constitute a driving source of a vehicle (here, a large vehicle such as truck).

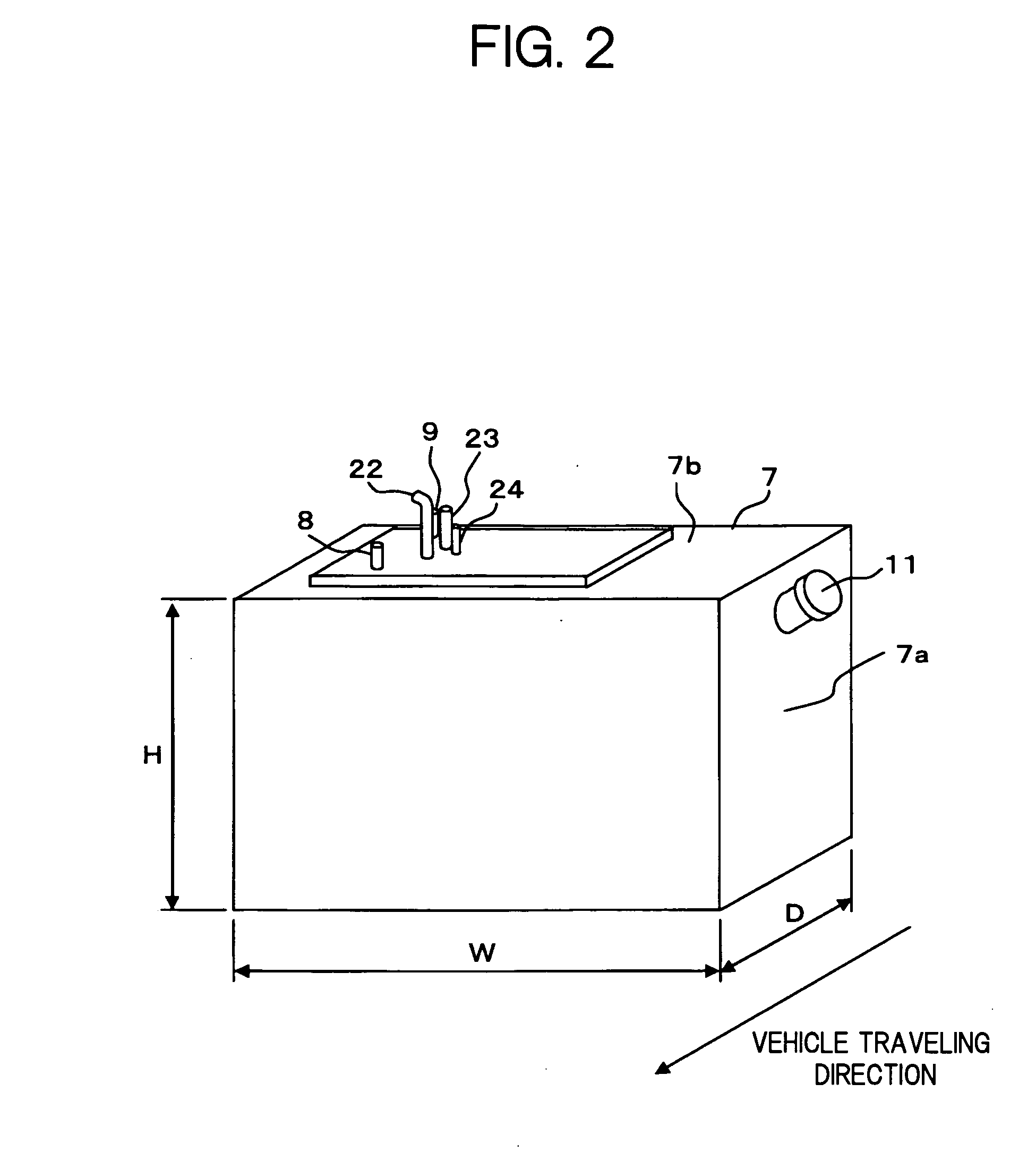

[0029]In an exhaust gas passage 2 of the engine 1, there is interposed a reducing catalytic converter 3 for nitrogen oxides (hereunder, referred to as “NOx”), and this reducing catalytic converter 3 accelerates reductive purification of NOx in engine exhaust gas. In the present embodiment, urea aqueous solution serving as a liquid reducing agent is supplied to the exhaust gas for NOx purification, and a urea aqueous solution injection nozzle 4 (hereunder, simply referred to as “injection nozzle”) is provided on the upstream of the reducing catalytic converter 3. The injection nozzle 4 is inserted into the exhaust gas passage 2 in a manner of passing through the pipe wall of the exhaust gas passa...

second embodiment

[0051]Moreover, in the second embodiment, a portion of the shielding plate also serves a function of the heat transfer plate. However, additional functions of the shielding plate are not limited to this. It is possible to constitute the shielding plate using other components provided in the liquid tank than the heat transfer plate.

[0052]Furthermore, the shape of the liquid tank is not limited to the rectangular shape described above, and it is possible to adopt various shapes. The direction of waves that occur in the liquid tank due to vibrations of the engine during operation is pre-checked, and the shape of the shielding plate (in other words, the position of the opening) is set so that waves occurring in this direction are blocked.

[0053]The present invention is not limited to a liquid tank for storing urea aqueous solution, and may also be applied to a liquid tank for storing other types of liquids, including other liquid reducing agents such as aqueous ammonia and fuel of hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com